Automatic detection equipment for automobile curtain

An automatic detection and curtain technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of low detection efficiency, large product errors, difficult product quality, etc., and reduce the detection process , high accuracy, and reduce the effect of manual misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

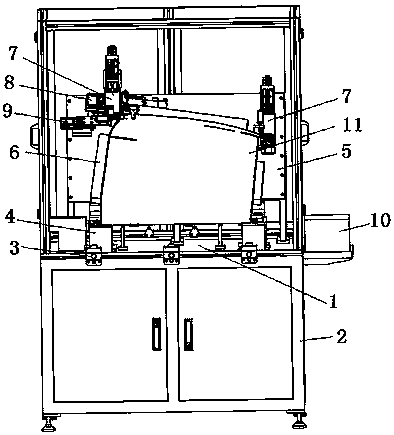

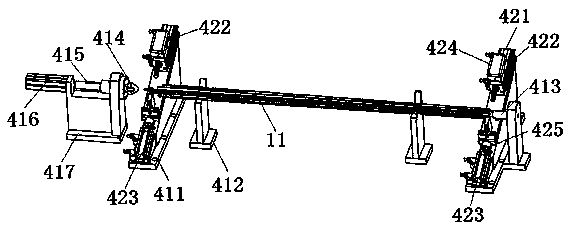

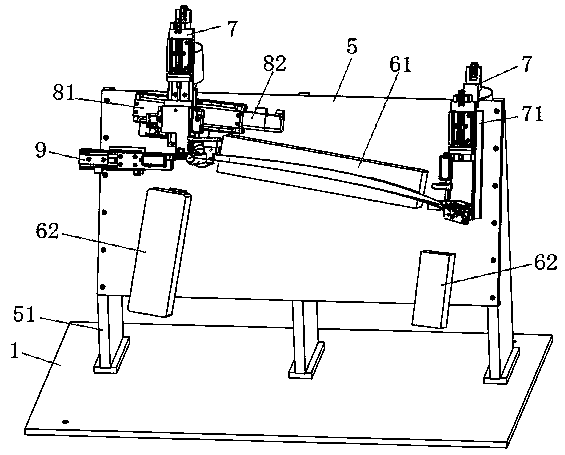

[0058] Such as figure 1 As shown, an automatic detection device for automobile curtains, including: a workbench 1, an electrical control cabinet 2 welded and fixed at the bottom of the workbench, a PLC controller is installed in the electrical control cabinet 2, and a passing wire is fixedly connected to the workbench 1 A control button 3 connected to the PLC controller; the workbench 1 is fixedly connected with a spindle shaft diameter detection mechanism 4 through fasteners, and the spindle shaft diameter detection mechanism 4 includes a spindle fixing mechanism for fixing the spindle on the workbench. device, and a shaft diameter detection device that is fixed on the main shaft fixing device by a fastener to detect the shaft diameter of the main shaft; it is located on the opposite surface of the main shaft shaft diameter detection mechanism 4, and a support plate is fixedly connected to the workbench by a fastener; The size detection device 6 for detecting the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com