Wrench capable of being quickly adjusted and with clamping function

A functional and fast technology, applied in the field of wrenches, can solve the problems of single function of adjustable wrench, lack of stable clamping, increase of operation time, etc., and achieve the effect of reducing the difficulty of disassembly, convenient disassembly, and fast tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

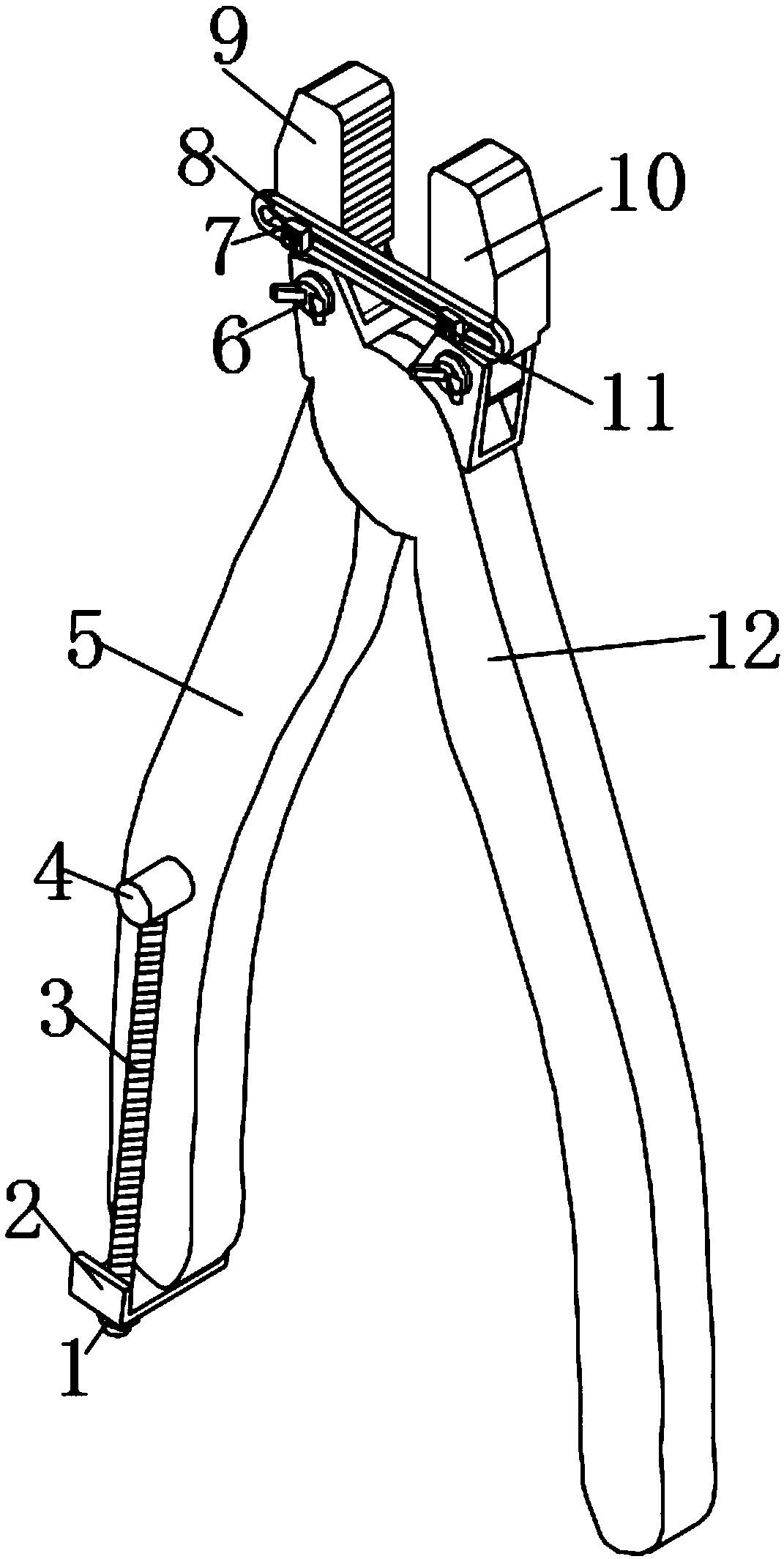

[0025] Embodiment one, with reference to Figure 1-4 , a wrench that can be quickly adjusted and has a clamping function, including a first handle 5, a first clamping block 9, a second clamping block 10, and a second handle 12, and the first handle 5 and the second handle 12 pass through each other The interlocking discs are hinged to each other, and the first handle 5 and the head end of the second handle 12 are respectively connected to the second clamping block 10 and the first clamping block 9 by fastening the adjusting bolt 6, so that the user can Adjusting the bolt 6 changes the fastening strength of the first clamping block 9 and the second clamping block 10, which facilitates the control of a certain angle to the first clamping block 9 and the second clamping block 10, and the first clamping block 9 and the second clamping block 10 are mirror images of each other, the end faces of the first clamping block 9 and the second clamping block 10 are provided with a slider fi...

Embodiment 2

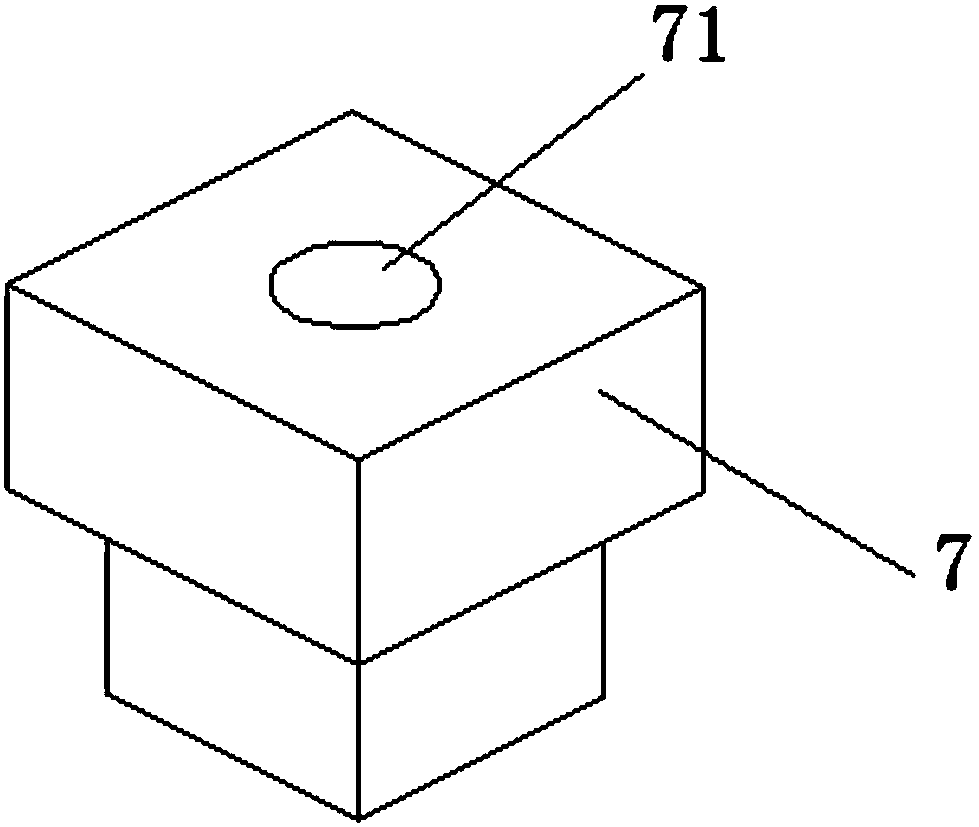

[0026] Embodiment two, refer to Figure 3-4 , the slider 7 is superimposed by two cuboids with a square cross section, wherein the width of the small cuboid is the same as the inner width of the chute rod 8, and the inner contour of the slider fixing groove 13 is the same as the outer contour of the small cuboid of the slider 7 , when the slider 7 moves in the chute rod 8, it can still keep the first clamping block 9 and the second clamping block 10 moving in parallel, and the first clamping block 9 and the second clamping block 10 are oppositely clamped Anti-slip strips are evenly provided on the surface to increase the surface roughness, thereby improving the clamping force of the clamped object.

Embodiment 3

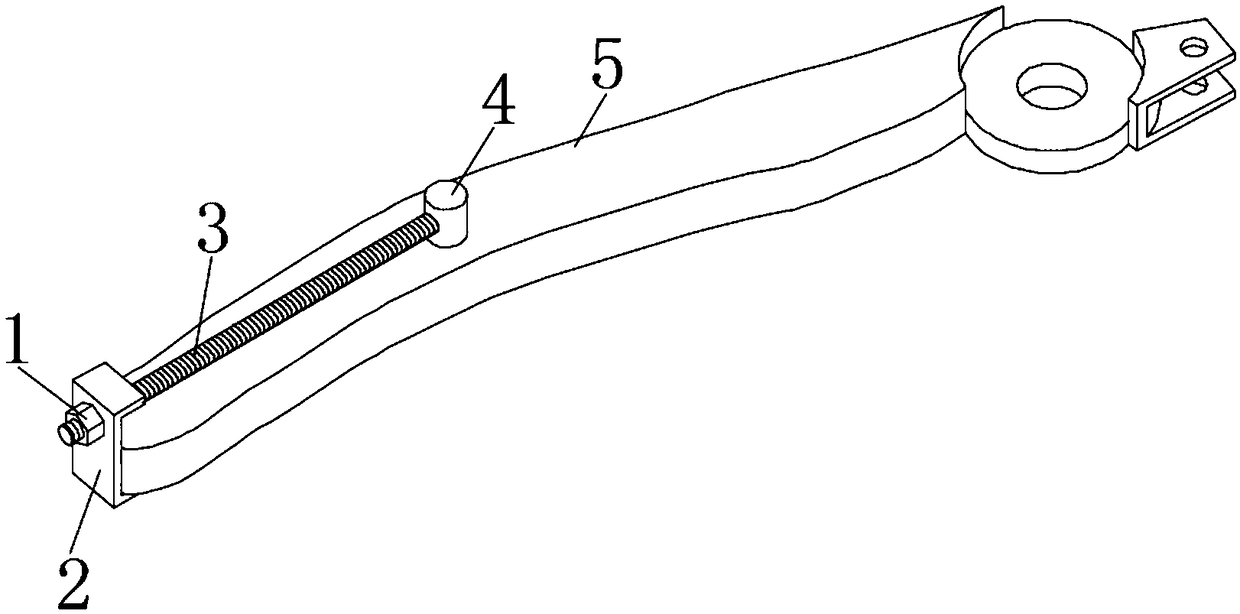

[0027] Embodiment three, refer to Figure 2-4 , the first handle 5 and the center position of the end face on the same side of the slider 7 are connected to the rotating seat 4 through rotation, the side wall of the rotating seat 4 is welded with the screw rod 3, the outer wall of the screw rod 3 is slidingly sleeved with the clamping plate 2, and the screw rod The end of 3 is screwed and connected with fastening nut 1, the cross-sectional profile of clamping plate 2 is U-shaped, and the length of screw 3 is greater than the distance from the axis of rotating seat 4 to the tail end of first handle 5, so that the user can pass clamping plate 2 The fixed angle control of the first handle 5 and the second handle 7 is realized, which is convenient for the user to connect the round tube to the first handle 5 or the second handle 12, thereby increasing the torque and reducing the difficulty of operation.

[0028] Working principle: when in use, when the first clamping block 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com