Edge and arc chamfering device machining for precision quartz crystal resonator

A technology of quartz crystals and resonators, which is applied in the field of crystal component processing technology, can solve problems such as track change and easy change of heart, achieve good wafer processing control capabilities, ensure design compliance, and improve wafer processing control capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

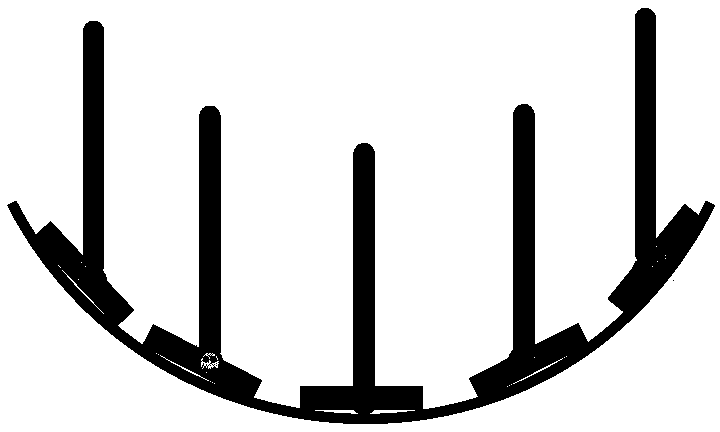

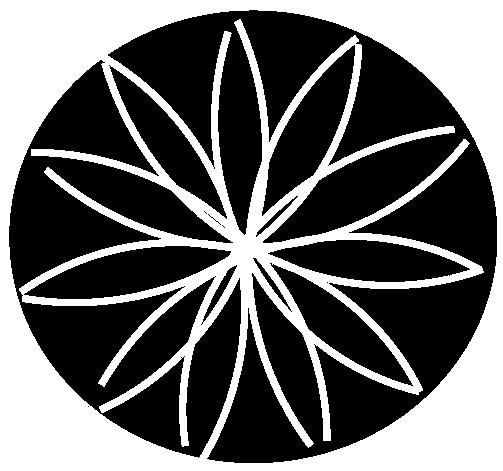

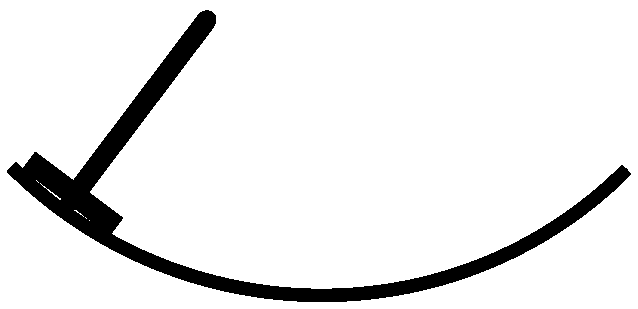

[0031] In order to illustrate the present invention more clearly, the present invention will be further described below with reference to the preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0032] The existing chamfering and arcing process usually follows the traditional crankshaft swing arm grinding machine. When chamfering and arcing grinding, a fixed stylus is installed vertically at the end of the swing arm of the equipment, and its spherical end is embedded in the center of the top of the wafer buckle carrying the wafer. In the hole, the wafer is pressed against the surface of the R bowl grinding disc. When the motor rotates, the R bowl and the crankshaft are driven by the motor to rotate at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com