Automatic Batch Grinding Tooling for Small Diameter Cylindrical Samples

A cylindrical sample and small-diameter technology, which is applied in the direction of manufacturing tools, grinding machines, positioning devices, etc., can solve the problems of low grinding efficiency, potential safety hazards, and difficulty in ensuring uniform grinding of the outer cylindrical surface, so as to reduce processing difficulty, Easy to operate and improve the efficiency of sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

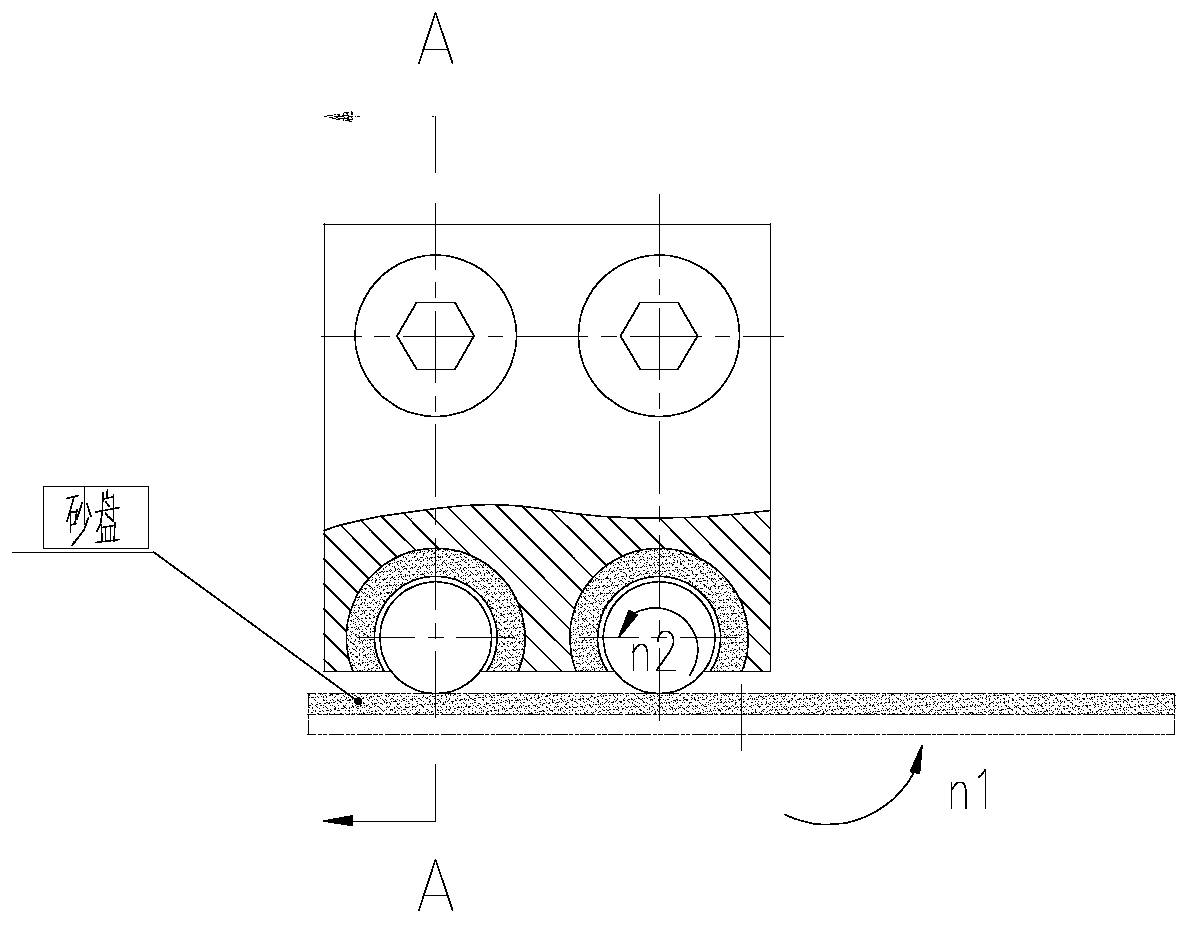

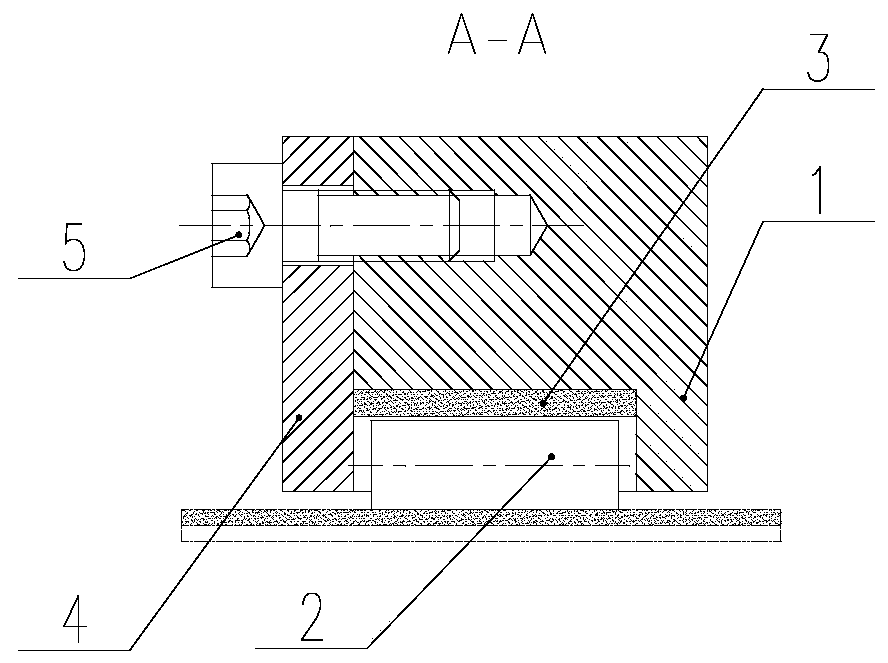

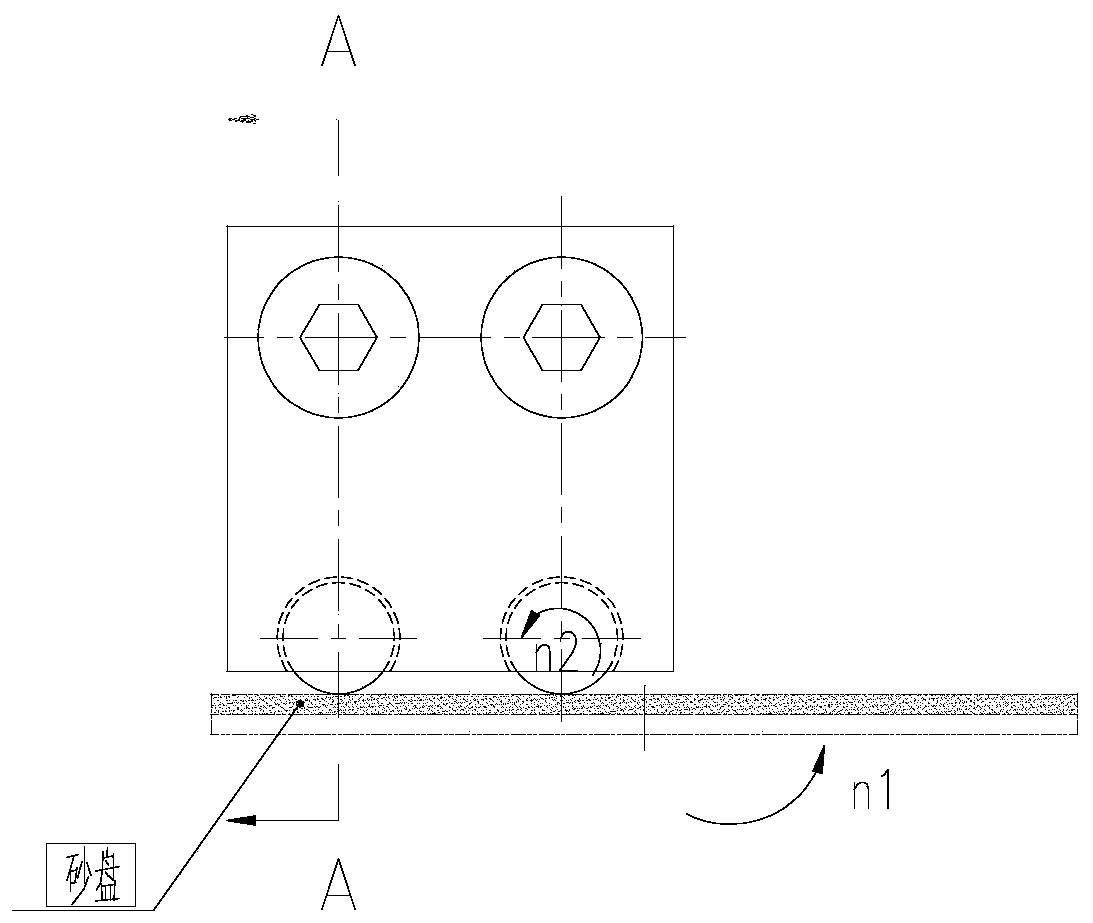

[0031] This embodiment provides a batch automatic grinding tool for small-diameter cylindrical samples, such as Figure 1-2 Shown: including base 1, sample hole 2, friction plate 3, side baffle 4 and bolt 5, the base 1 is a cuboid structure, made of wear-resistant material, the bottom surface is horizontal, and the bottom surface is arranged in parallel with 2 suitable sizes The sample hole 2, the sample hole 2 adopts one end opening method, and the end surface has a large semicircular structure, so as to ensure that the cylindrical surface of the sample to be tested is exposed to the bottom surface of the fixture and does not fall out during the preparation process; the friction plate 3 is made of powder metallurgy material, and the end surface It has a concentric structure with the sample hole 2, the outer diameter is slightly smaller than the inner diameter of the sample hole 2, and the inner diameter is slightly larger than the outer diameter of the sample to be tested, so ...

Embodiment 2

[0033] This embodiment provides a batch automatic grinding tool for small-diameter cylindrical samples, such as Figure 3-4 As shown: including base 1, sample hole 2, spring device 3, side baffle 4 and bolt 5, the base 1 is a cuboid structure, made of wear-resistant material, the bottom surface is horizontal, and the bottom surface is arranged in parallel with two suitable sizes The sample hole 2 adopts the opening method at one end, and the end surface is a large semicircular structure, so as to ensure that the cylindrical surface of the sample to be tested is exposed to the bottom surface of the fixture and does not fall out during the preparation process, and the other end is processed to match the bolts of the spring system The bolt hole; the spring device is composed of three parts: bolt 3-1, spring 3-2, and ball head 3-3, wherein the bolt 3-1 matches the bolt hole of the base, and the two ends of the spring are respectively connected and fixed with the bolt head and the b...

Embodiment 3

[0035] This embodiment provides a batch automatic grinding tool for small-diameter cylindrical samples, such as Figure 5-7Shown: including base 1, base sample hole 2, U-shaped cover plate 3, friction plate 4 and bolt 5, the base 1 is a cuboid structure, made of ordinary metal, the bottom surface is horizontal, and the bottom surface is arranged in parallel with 2 A sample hole 2 with a suitable size, the sample hole 2 adopts a through hole method, and the hole wall is polished. In addition, the end surface of the sample hole is a semicircular structure; the cover plate 3 is made of wear-resistant material, and its thickness is smaller than that of the base sample hole. Radius, the same number of rectangular sample holes are processed corresponding to the sample holes of the base, the friction plate 4 is bonded to both sides of the rectangular sample holes, the cover plate 3 and the base 1 are connected by bolts 5, after the two are assembled Part of the cylindrical surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com