Layer-by-layer self-assembled coating modified cotton fiber heavy metal ion adsorption material and preparation method thereof

A technology of layer-by-layer self-assembly and heavy metal ions, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of secondary pollution of the environment and difficulty in recycling, so as to avoid secondary pollution, Guarantee the adsorption efficiency and overcome the effect that is difficult to recover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

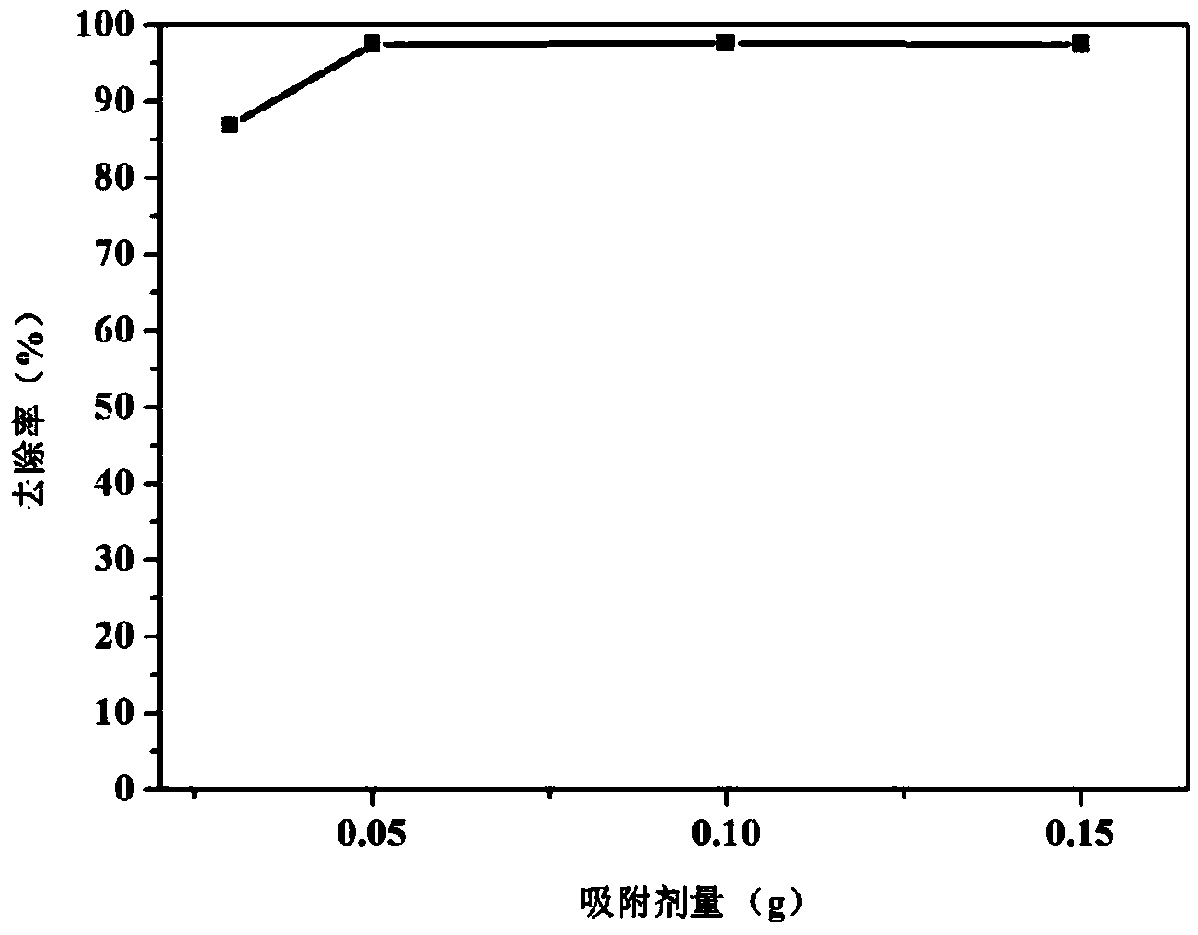

[0030] Cotton fiber adsorption material modified by polyethyleneimine / sodium alginate coating

[0031] A cotton fiber adsorption material is composed of a base material and a modification layer, the base material is cotton fiber, the modification layer includes more than one group of layer-by-layer self-assembled coatings, and the layer-by-layer self-assembled coatings are formed by electrostatic The layer-by-layer self-assembly method modifies the positively charged assembly layer and the negatively charged assembly layer on the surface of the substrate. In the modification layer, the number of layer-by-layer self-assembled coatings is 9 groups.

[0032] Its preparation method is:

[0033] (a) Preprocessing

[0034] The cotton fabric was placed in an aqueous solution containing 50 g / L of 3-chloro-2-hydroxypropyltrimethylammonium chloride and 36 g / L of sodium hydroxide, and stirred at 90 °C for 2 h. After the reaction is completed, the cotton fabric is taken out and washed ...

Embodiment 2

[0042] Cotton fiber adsorption material modified by chitosan / sodium polybenzenesulfonate coating

[0043] A cotton fiber adsorption material is composed of a base material and a modification layer, the base material is cotton fiber, the modification layer includes more than one group of layer-by-layer self-assembled coatings, and the layer-by-layer self-assembled coatings are formed by electrostatic The layer-by-layer self-assembly method modifies the positively charged assembly layer and the negatively charged assembly layer on the surface of the substrate. In the modification layer, the number of layer-by-layer self-assembled coatings is 20 groups.

[0044] Its preparation method is:

[0045] (a) Preprocessing

[0046] The cotton fabric was put into an aqueous solution containing 50g / L of 3-chloro-2-hydroxypropyltrimethylammonium chloride and 36g / L of sodium hydroxide, and stirred at 90°C for 2h. Take out and wash until neutral;

[0047] (b) Solution preparation

[0048...

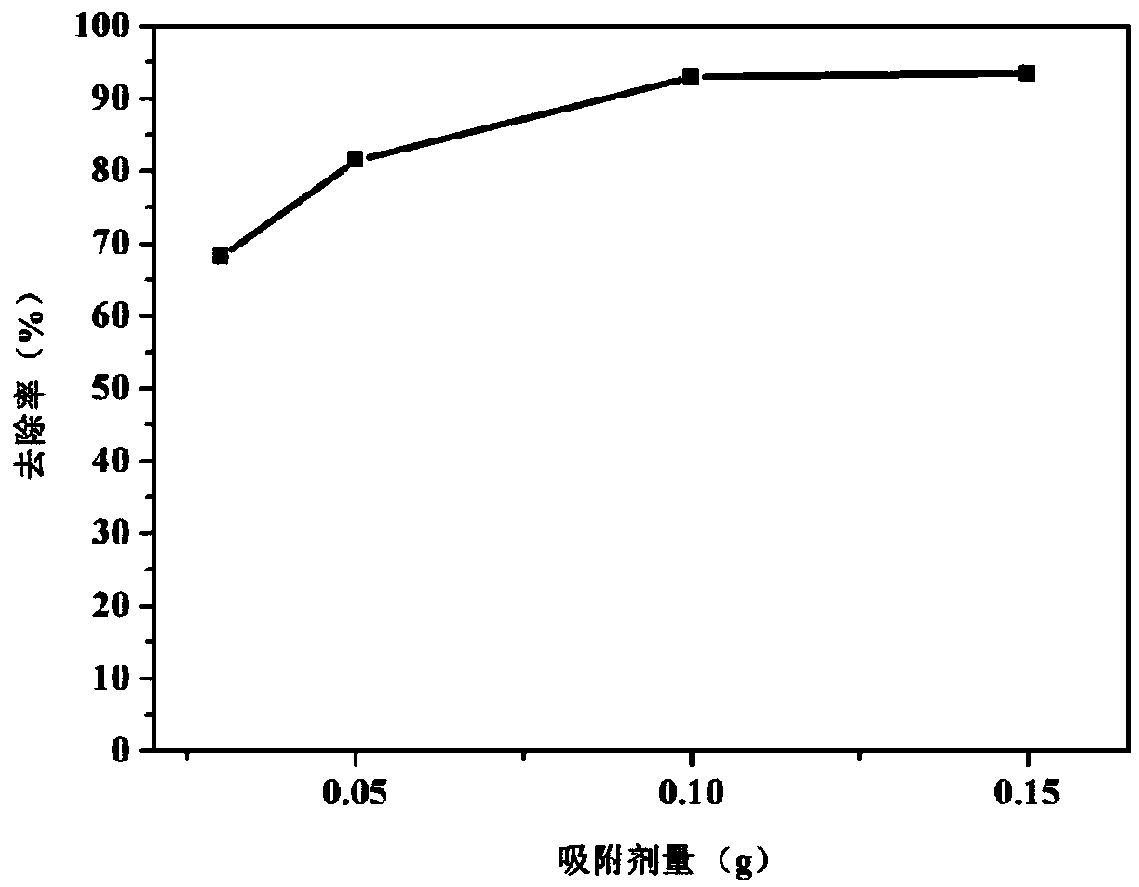

Embodiment 3

[0054] Cotton fiber adsorption material modified by chitosan / sodium alginate coating

[0055] A cotton fiber adsorption material is composed of a base material and a modification layer, the base material is cotton fiber, the modification layer includes more than one group of layer-by-layer self-assembled coatings, and the layer-by-layer self-assembled coatings are formed by electrostatic The layer-by-layer self-assembly method modifies the positively charged assembly layer and the negatively charged assembly layer on the surface of the substrate. In the modification layer, the number of layer-by-layer self-assembled coatings is 9 groups.

[0056] Its preparation method is:

[0057] (a) Preprocessing

[0058] The cotton fabric was placed in an aqueous solution containing 50 g / L of 3-chloro-2-hydroxypropyltrimethylammonium chloride and 36 g / L of sodium hydroxide, and stirred at 90 °C for 2 h. After the reaction is completed, the cotton fabric is taken out and washed to neutra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com