Recycling system for condensate after reforming of methane steam in coke oven gas

A coke oven gas and condensate technology, which is applied in the field of coal chemical waste liquid utilization, can solve the problems of waste of high-quality water resources and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

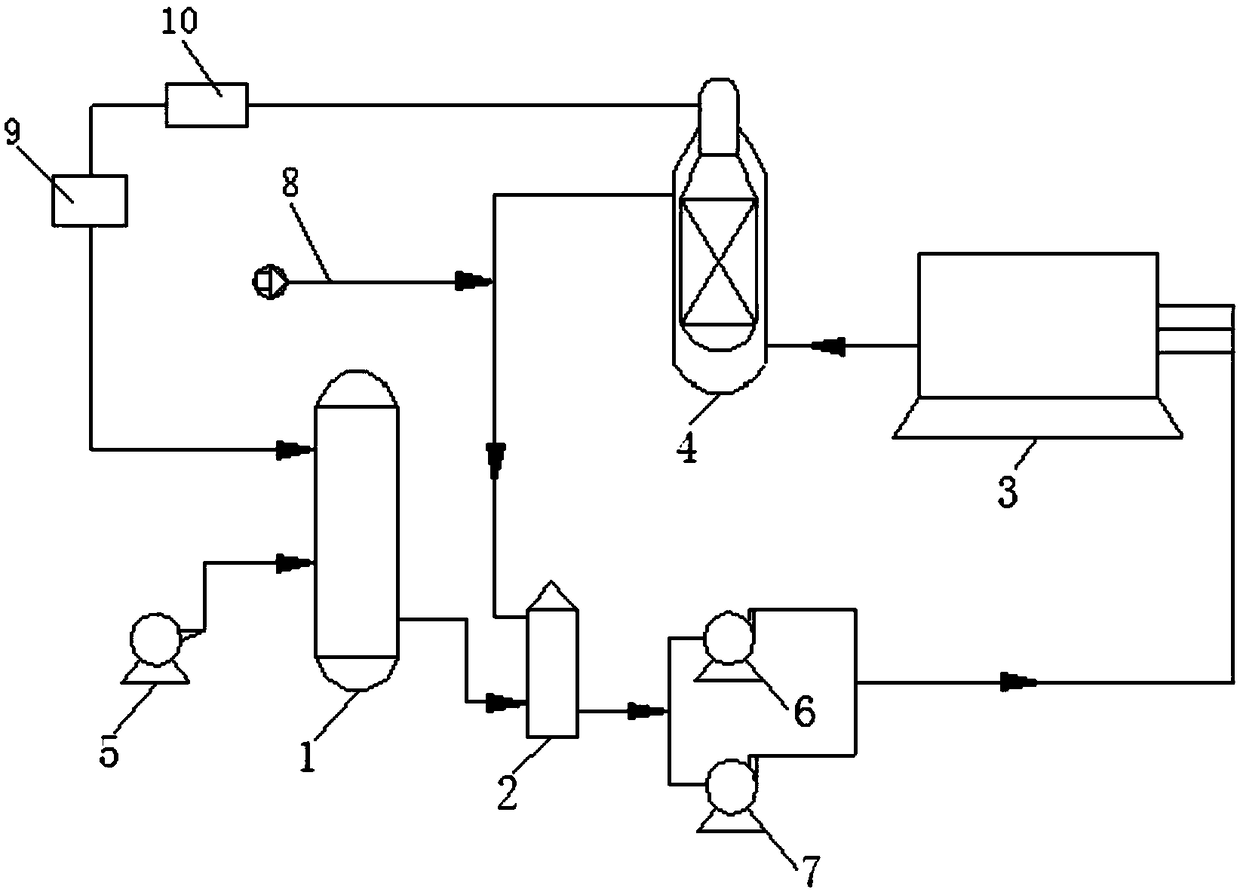

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] The invention discloses a recycling system for condensate after methane steam reforming in coke oven gas, such as figure 1 As shown, including the reformer 4, the reformer 4 is used to greatly reduce the content of methane in the coke oven gas, and reduce the content of methane in the coke oven gas from 19-21% (volume fraction) to below 1%.

[0017] The temperature of the gas discharged from the gas outlet of the reformer 4 is generally around 980°C. It needs to be cooled and preheated for recycling. Therefore, a heat exchange unit 10 is installed on the pipeline between the reformer 4 and the gas-liquid separator 9 , the heat exchange unit 10 includes one or more of a waste heat boiler, a coke oven preheater, a boiler feed water preheater, a desalted water preheater and a water cooler, which can be specifically configured according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com