Method for identifying fritillaria thunbergii, fritillaria cirrhosa and fritillaria ussuriensis with pyrolysis-gas chromatography fingerprints

A technology of pyrolysis gas chromatography and gas chromatography, which is applied in the field of Chuan Fritillaria and Pyramid Fritillaria, combining cracking-gas chromatography with fingerprints to identify Zhejiang Fritillaria, can solve the problems of lack of conjugate bonds, poor volatility of alkaloids, and consume a lot of time and effort. Solve problems such as organic solvents, achieve the effect of saving experimental time, simplifying experimental steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

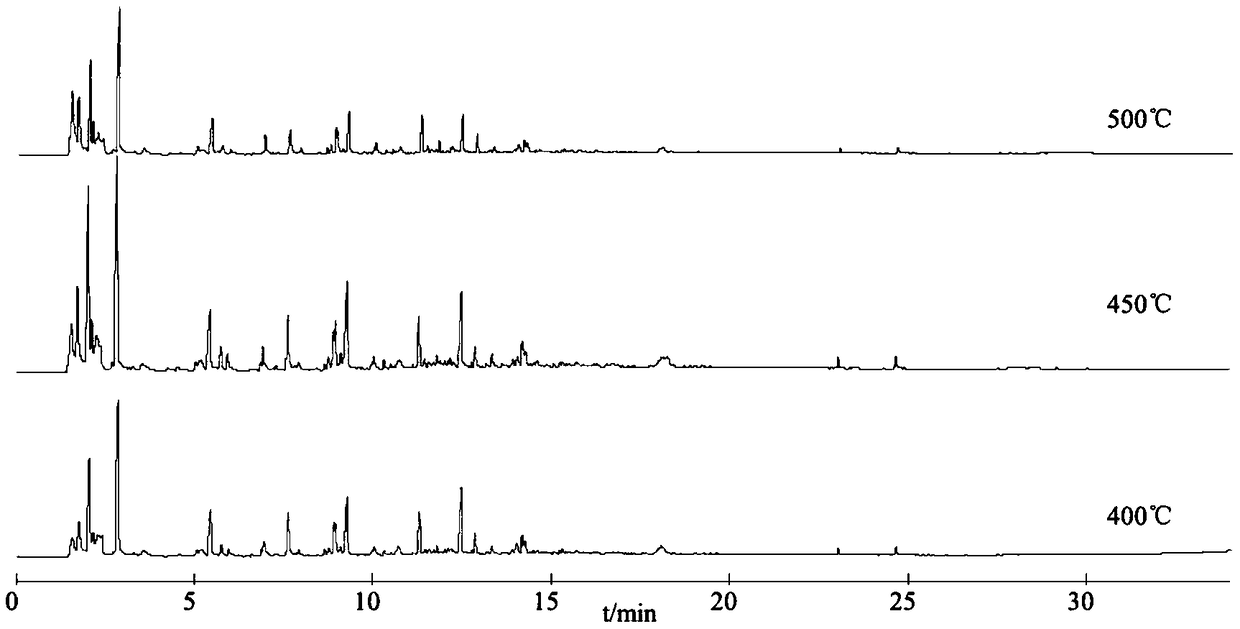

[0030] The selection of embodiment 1 cracking temperature

[0031] (1) Instruments and reagents

[0032] American Thermo Trace GC Ultra gas chromatograph with hydrogen flame detector (FID); Japanese FrontierPY-2020iD double-click vertical micro-furnace cracker.

[0033] Buy local Fritillaria, Fritillaria Chuan, and Pingbei decoction pieces from pharmacies in Zhejiang, Sichuan, Jilin, etc., remove impurities such as roots and hairs that are visible to the naked eye, grind them, pass through a 60-100 mesh sieve, and make Fritillaria powder for later use. The sample list is shown in Table 1.

[0034]

[0035] (2) Experimental method

[0036]Accurately weigh about 0.3 mg of Zhe Fritillaria (ZB1) sample powder, put it into a sample cup, fix it on the injection rod, and put it into the cracker installed above the GC inlet. At this time, the sample is at room temperature. After the temperature of the cracker reaches the appropriate temperature (400°C, 450°C, 500°C), press the s...

Embodiment 2

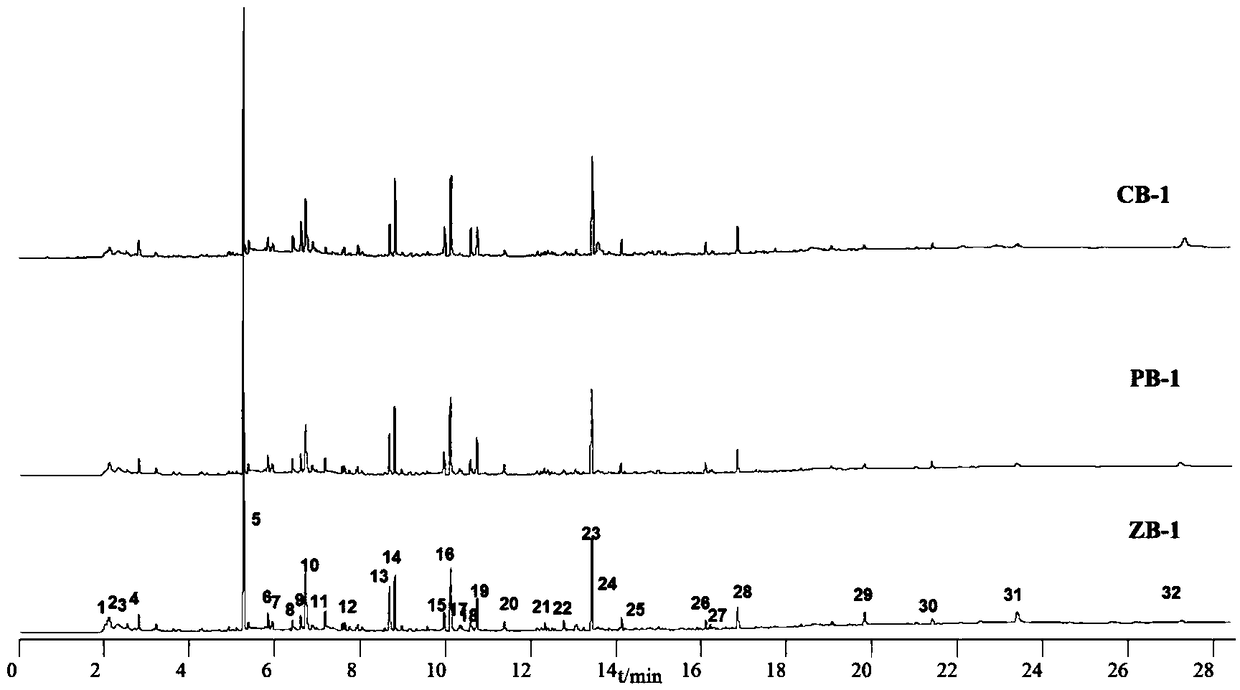

[0042] The pyrolysis gas chromatographic analysis of different Fritillaria species of embodiment 2

[0043] American Thermo Trace GC Ultra gas chromatograph with hydrogen flame detector (FID); Japanese FrontierPY-2020iD double-click vertical micro-furnace cracker.

[0044] Gas chromatographic conditions: UA-CW capillary column (30m x 0.25mm i.d.x 0.25um, PEG20), heating program: initial temperature 40°C, rise to 90°C at a rate of 20°C / min, then rise to 90°C at a rate of 10°C / min 250°C, hold for 5min; inlet temperature is 250°C, detector temperature is 250°C, split ratio 30:1; carrier gas: nitrogen, flow rate 1.0mL / min.

[0045] Cracker conditions: cracking furnace temperature: 450°C; interface temperature between cracker and gas chromatograph: 250°C.

[0046] Accurately weigh 0.3 mg of Zhe Fritillaria (ZB1), Chuan Fritillaria (CB1), and Flat Fritillaria (PB1) prepared according to the method of Example 1 respectively, put them into sample cups, fix them on the sampling rod, a...

Embodiment 3

[0049] The investigation of embodiment 3 reproducibility

[0050] American Thermo Trace GC Ultra gas chromatograph with hydrogen flame detector (FID); Japanese FrontierPY-2020iD double-click vertical micro-furnace cracker.

[0051] Gas chromatographic conditions: UA-CW capillary column (30m x 0.25mm i.d.x 0.25um, PEG20), heating program: initial temperature 40°C, rise to 90°C at a rate of 20°C / min, then rise to 90°C at a rate of 10°C / min 250°C, hold for 5min; inlet temperature is 250°C, detector temperature is 250°C, split ratio 30:1; carrier gas: nitrogen, flow rate 1.0mL / min.

[0052] Cracker conditions: cracking furnace temperature: 450°C; interface temperature between cracker and gas chromatograph: 250°C.

[0053] Accurately weigh 0.3 mg of 5 parts of Fritillaria (ZB1) samples prepared by the method of Example 1 respectively and put them into the sample cup, fix them behind the sample rod, and pack into the cracker installed on the top of the GC sample inlet. At this time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com