Preparation method of fructose syrup

A high fructose syrup and glucose technology, applied in the field of food additives, can solve the problems of cumbersome maintenance, increase the difficulty of sewage treatment, complicated operation, etc., and achieve the effects of saving production working capital, high production flexibility, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The embodiment of the present invention relates to a preparation method of fructose syrup, comprising the following steps:

[0049] Step 1. Turn on the sugar liquid storage tank or reaction tank with stirring function, and adjust the rotation speed to 75-90rpm. Then add glucose solution with a glucose content of more than 93%, magnesium sulfate and sodium metabisulfite, stir and mix evenly to obtain a mixture.

[0050] The above-mentioned glucose solution is unrefined glucose solution, which contains pigments, impurities and other salts. In the traditional preparation method of fructose syrup, these substances will affect the product quality, and will block the heterogeneous column when passing through the column, affecting the efficiency of converting glucose into fructose. Therefore, it is necessary to add magnesium sulfate and sodium metabisulfite to the glucose solution after decolorization and impurity removal. And adopt the method of the present invention, becau...

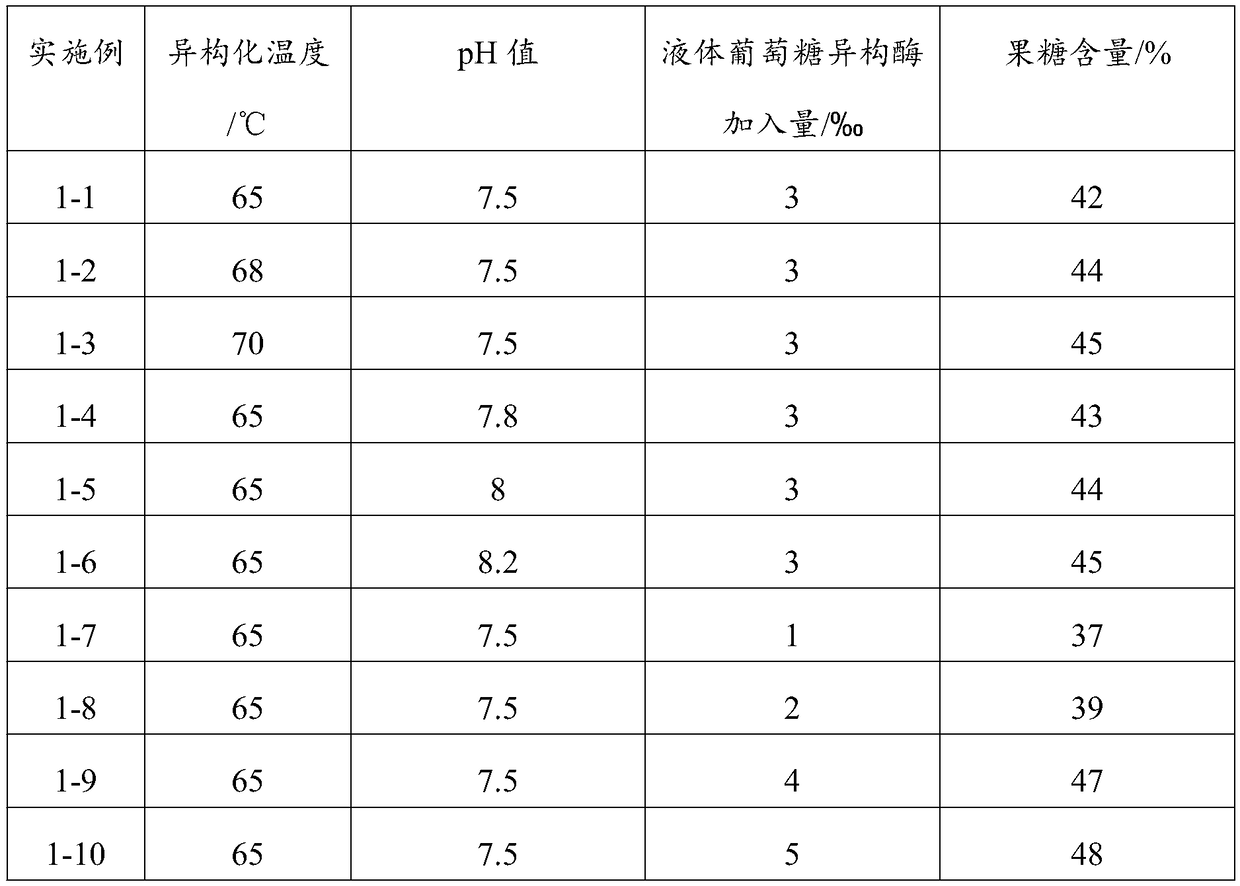

Embodiment 1

[0075] Preparation of F42 Fructose Syrup Using Ordinary Glucose Solution

[0076] Step 1. Turn on the reaction tank with stirring function, and adjust the rotation speed to 75-90rpm. Add the glucose liquid with a dry matter content of 30% and a glucose content of 93% into the reaction tank, magnesium sulfate and sodium metabisulfite, stir and mix evenly to obtain a mixture. Wherein, the content of magnesium sulfate in the glucose solution is 150ppm, and the content of sodium metabisulfite in the glucose solution is 100ppm.

[0077] Step 2: Adjust the pH value of the mixture to 7.0-8.2 with soda ash, and then raise the temperature to 60-70°C.

[0078] Step 3, adding liquid glucose isomerase to the mixture, the mass content of the liquid glucose isomerase in the glucose solution is 1-5‰. The enzyme activity is 5000u / ml.

[0079] Step 4: Stir and mix evenly, then heat-preserve and react for 24 hours to obtain crude fructose syrup with a fructose content of 42-44%.

[0080] St...

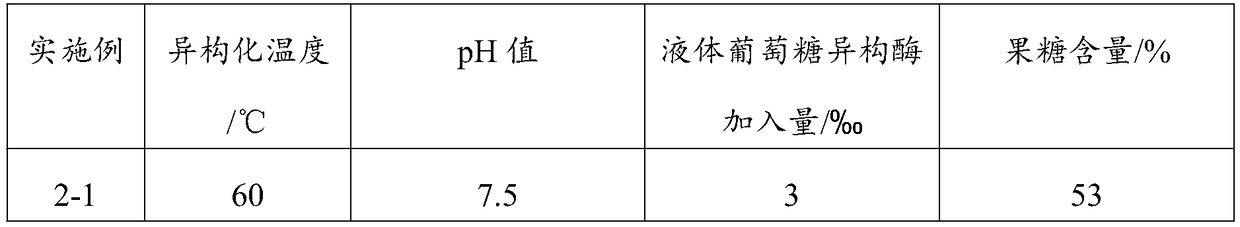

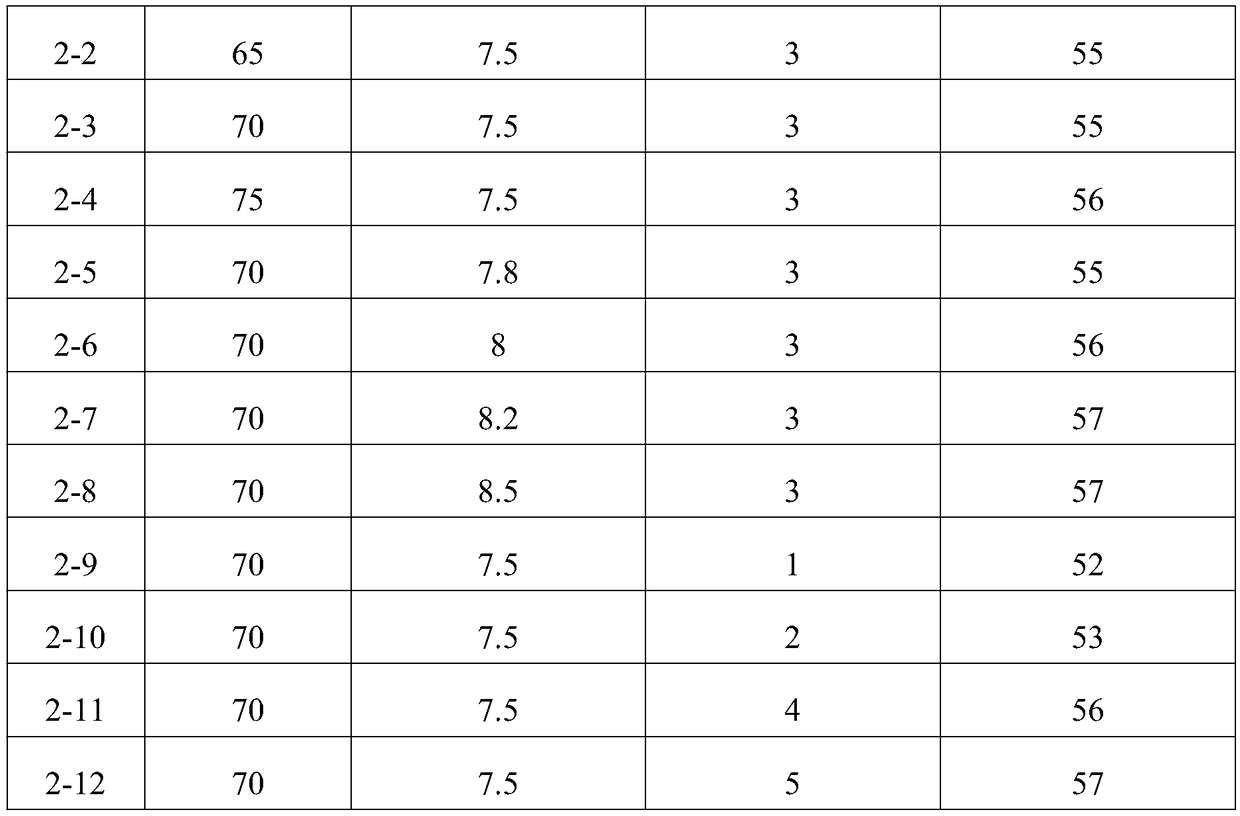

Embodiment 2

[0094] Preparation of F55 Fructose Syrup Using Refined Glucose Liquid

[0095] Step 1. Turn on the reaction tank with stirring function, and adjust the rotation speed to 75-90rpm. Adding refined glucose solution with a dry matter content of 30% and a glucose content of 95% into the reaction tank, magnesium sulfate and sodium pyrosulfite, stirring and mixing evenly to obtain a mixture. Wherein, the content of magnesium sulfate in the glucose solution is 150ppm, and the content of sodium metabisulfite in the glucose solution is 100ppm.

[0096] Step 2: Adjust the pH value of the mixture to 7.0-8.5 with soda ash, and then raise the temperature to 60-75°C.

[0097] Step 3, adding liquid glucose isomerase to the mixture, the mass content of the liquid glucose isomerase in the glucose solution is 1-5‰. The enzyme activity is 10000u / ml.

[0098] Step 4: Stir and mix evenly, then heat-preserve and react for 18 hours to obtain crude fructose syrup with a fructose content of 54-57%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com