Method for producing high-quality maltodextrin

A technology of maltodextrin and production method, which is applied in the field of maltodextrin, can solve the problems of unguaranteed long-term storage, no mention of modification effect, no effect, etc., to meet market needs, broaden the range of DE value, improve The effect of branching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

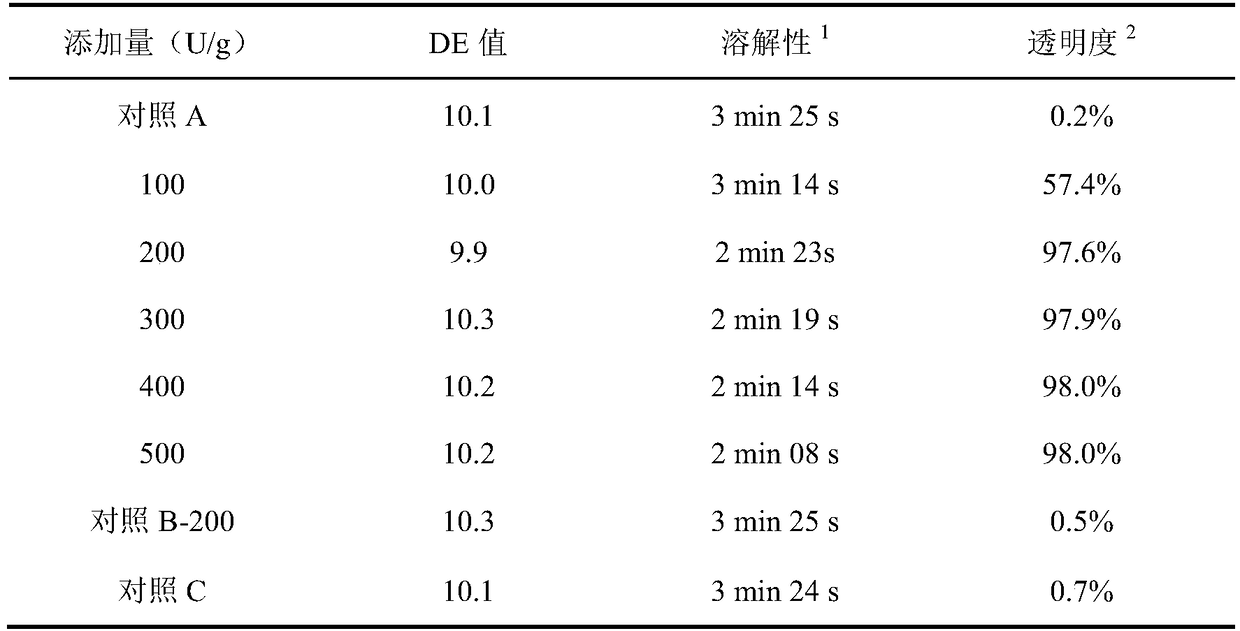

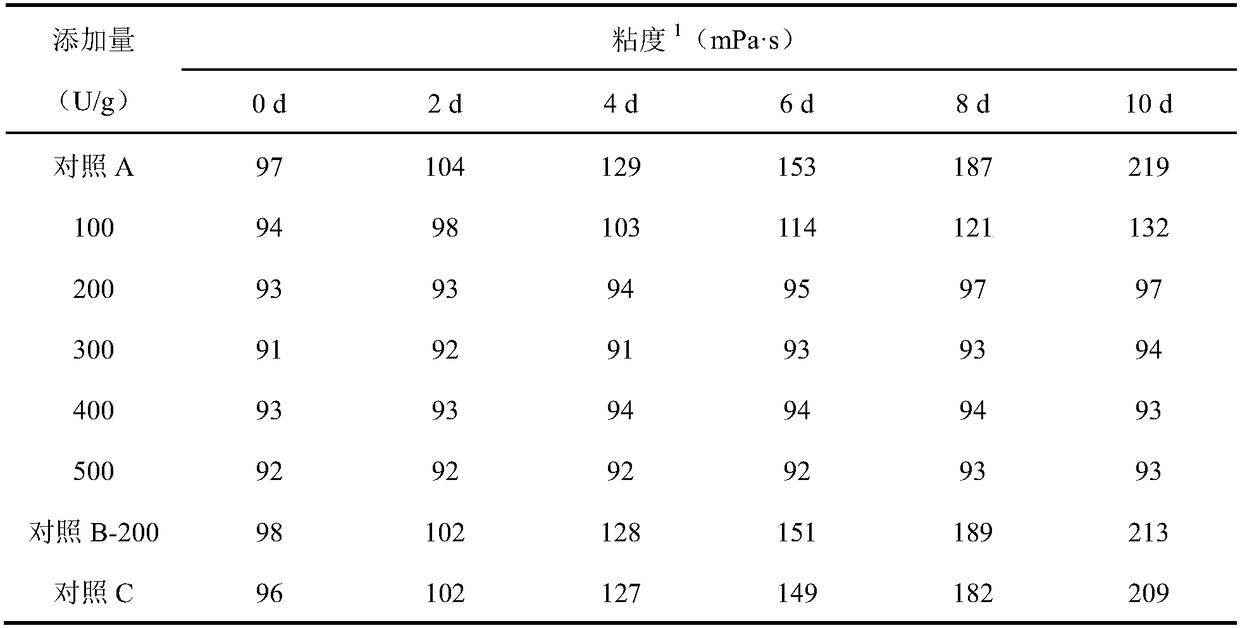

[0034] Example 1: The effect of the amount of starch branching enzyme added on the properties of maltodextrin

[0035] (1) Slurry preparation: adjust the starch into 35% starch milk, keep it warm at 70°C for 30 minutes, add high-temperature-resistant α-amylase of 12U / g starch on a dry basis and 0.2% calcium chloride, and adjust the pH after stirring evenly is 6.5.

[0036] (2) Injection liquefaction: Use a low-pressure steam injection liquefier for injection. The material pressure of the first injection is 0.35MPa, the steam pressure is 0.1MPa, the temperature is 105°C, and the time is 8min. After that, it is liquefied at 90°C for 40min. Carry out the second spraying to kill the enzyme, the material pressure is 0.35MPa, the steam pressure is 0.3MPa, the temperature is 140°C, and the time is 5min.

[0037] (3) Starch branching enzyme action: After the liquefied solution in (2) is cooled below 50°C, add starch branching enzymes from Rhodothermus obamensis at 100, 200, 300, 400, 5...

Embodiment 2

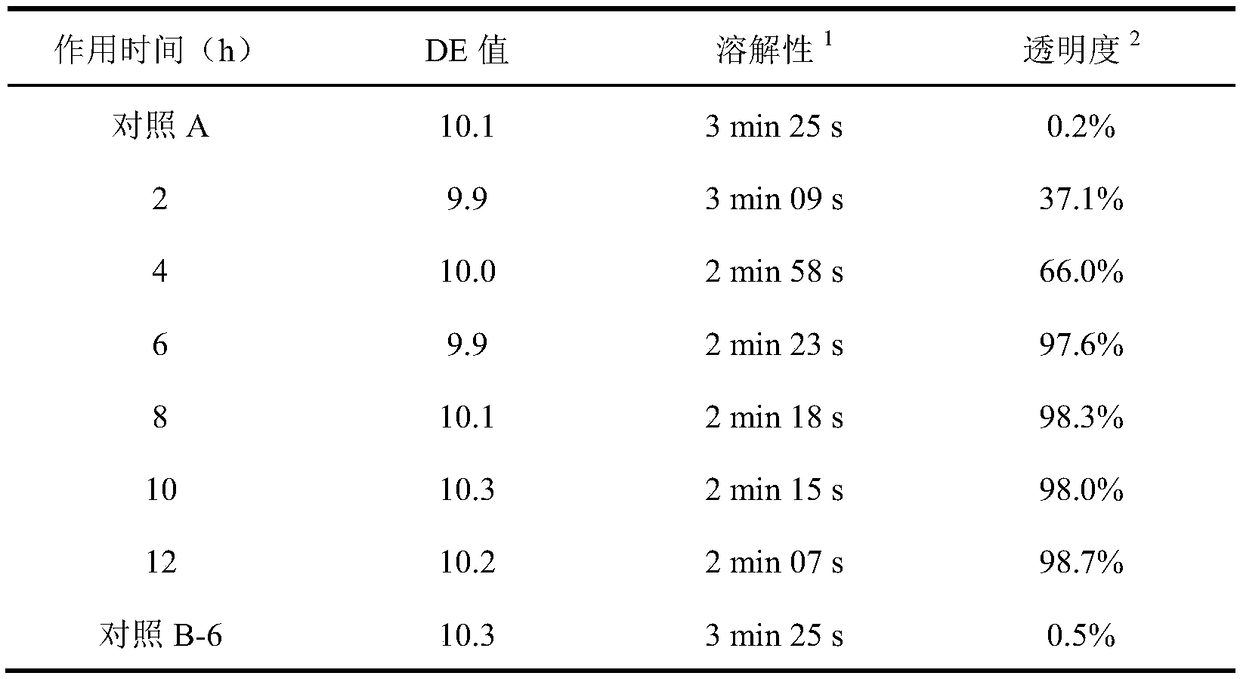

[0054] Example 2: Effect of starch branching enzyme action time on properties of maltodextrin

[0055] (1) Slurry preparation: adjust the starch into 35% starch milk, keep it warm at 70°C for 30 minutes, add high-temperature-resistant α-amylase of 12U / g starch on a dry basis and 0.2% calcium chloride, and adjust the pH after stirring evenly is 6.5.

[0056] (2) Injection liquefaction: Use a low-pressure steam injection liquefier for injection. The material pressure of the first injection is 0.35MPa, the steam pressure is 0.1MPa, the temperature is 105°C, and the time is 8min. After that, it is liquefied at 90°C for 40min. Carry out the second spraying to kill the enzyme, the material pressure is 0.35MPa, the steam pressure is 0.3MPa, the temperature is 140°C, and the time is 5min.

[0057] (3) Starch branching enzyme action: After cooling the liquefied solution in (2) below 50°C, add 200 U / g Rhodothermus obamensis starch branching enzyme on a dry basis, adjust the pH to 7.0, ...

Embodiment 3

[0075] Example 3: Effect of starch branching enzyme action temperature on properties of maltodextrin

[0076] (1) Slurry preparation: adjust the starch into 35% starch milk, keep it warm at 70°C for 30 minutes, add high-temperature-resistant α-amylase of 12U / g starch on a dry basis and 0.2% calcium chloride, and adjust the pH after stirring evenly is 6.5.

[0077] (2) Injection liquefaction: Use a low-pressure steam injection liquefier for injection. The material pressure of the first injection is 0.35MPa, the steam pressure is 0.1MPa, the temperature is 105°C, and the time is 8min. After that, it is liquefied at 90°C for 40min. Carry out the second spraying to kill the enzyme, the material pressure is 0.35MPa, the steam pressure is 0.3MPa, the temperature is 140°C, and the time is 5min.

[0078] (3) Starch branching enzyme action: After the liquefied liquid in (2) is cooled below 50°C, add 200U / g Rhodothermus obamensis starch branching enzyme, adjust the pH to 7.0, and respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com