Reversible Pickering emulsion, preparation method of reversible Pickering emulsion, and reversible high-temperature high-density drilling fluid

A Pickering emulsion and drilling fluid technology, applied in the field of drilling fluid, can solve the problems of high particle property dependence, unknown, non-reversible, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

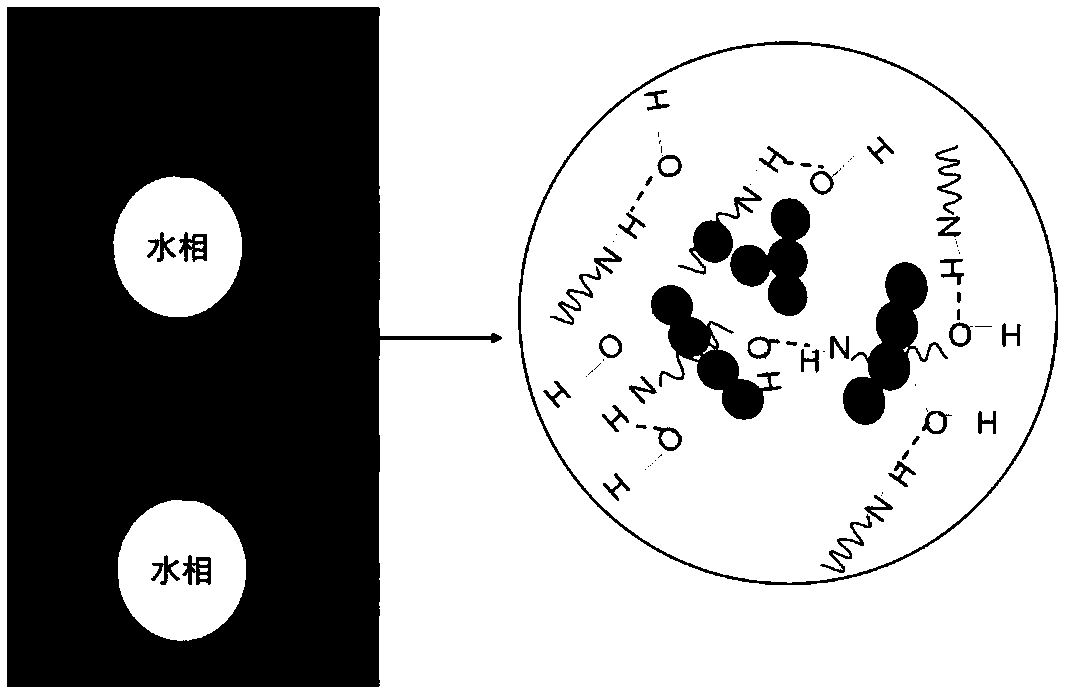

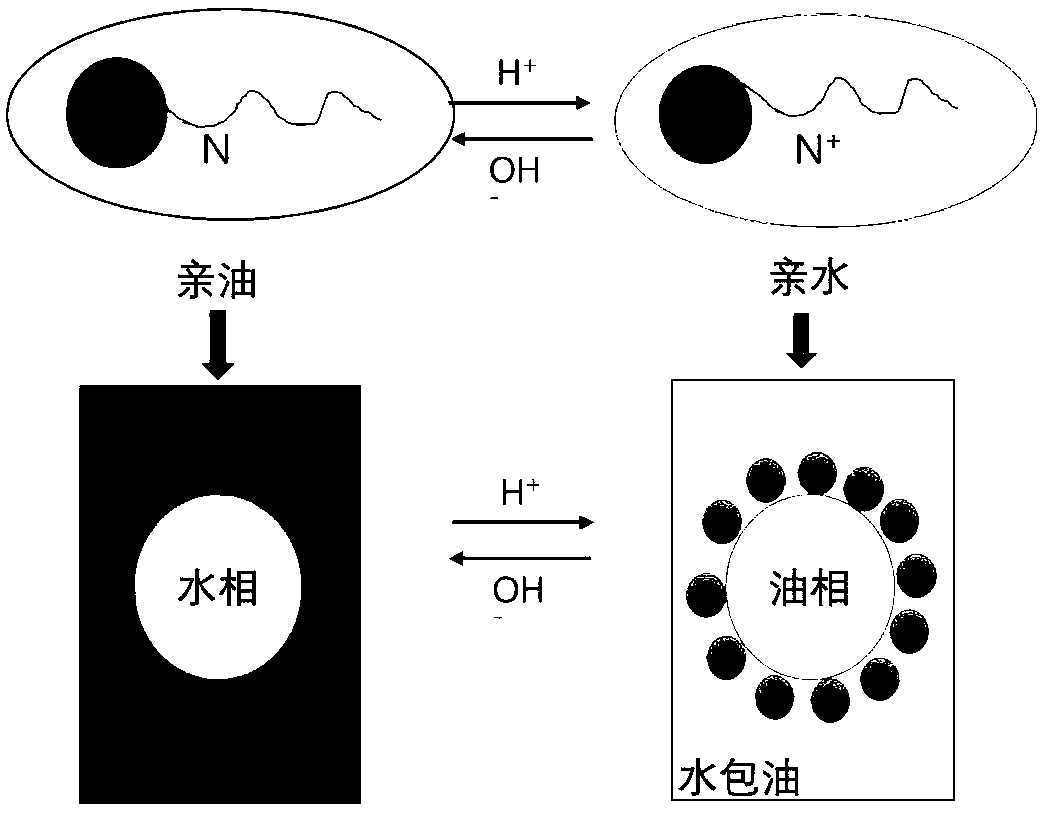

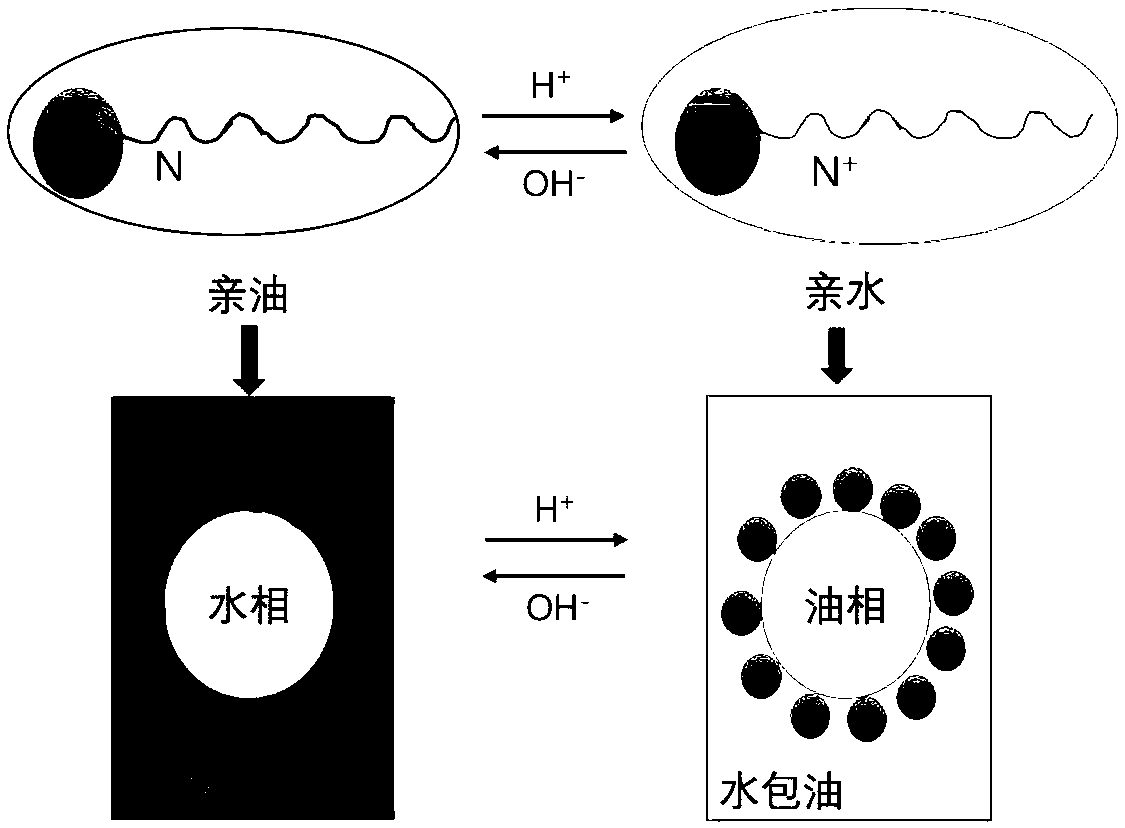

Method used

Image

Examples

Embodiment 1

[0145] Step 1, in situ activation.

[0146] Take 100 parts by mass of 0# diesel oil as the oil phase, add 2 parts by mass of lipophilic nano-silica particles as nanoparticles, and use balls with a diameter of 5mm, 10mm or 20mm to mill in a polyethylene ball mill tank for 10~ Mix well for 20 minutes, then add 0.2 parts by mass of surfactant n-pentylamine, continue ball milling for 5-24 hours, stop until the gel strength is 1-2g / cm2, complete the in-situ activation of nanoparticles, and obtain weak gel state oil phase suspension.

[0147] Step two, emulsification.

[0148] Take the weak gel state oil phase suspension in step 1, slowly add 125 parts by mass of deionized water as the water phase, emulsify with a homogenizer, the diameter of the metal vibrating rod of the homogenizer is 10mm-50mm, and the length of the metal vibrating rod is 100mm ~450mm, the frequency is 10000~13500r / min, and the emulsification time is 5min~4h. After the emulsification is completed, cool down to...

Embodiment 8

[0153] Step one, in situ activation.

[0154] Take 60 parts by mass of 0# diesel oil as the oil phase, then add 0.2 parts by mass of surfactant diethylenetriamine, stir and mix by magnetic force, use a rotor with a diameter of 1 cm to 10 cm, and the power of the magnetic stirrer is 100W to 300W, and stir for 10 to 30min, then add 4 parts by mass of lipophilic nano-silica particles as nanoparticles, continue magnetic stirring for 12-24h, stop until the gel strength is 1-2g / cm2, complete the in-situ activation of nanoparticles, and obtain weak Gel-state oil phase suspension.

[0155] Step two, emulsification.

[0156] Take the weak gel state oil phase suspension in step 1, slowly add 40 parts by mass of deionized water as the water phase, stir and emulsify with a high-speed stirrer, the stirring speed is 8000-12000r / min, the emulsification time is 10-20min, emulsification After completion, the ice bath was cooled to room temperature to obtain a reversible Pickering emulsion. ...

Embodiment 9

[0158] Take 80 parts by mass of gas oil as the oil phase, add 2 parts by mass of lipophilic nano-magnesium dioxide particles as nanoparticles, use an ultrasonic cell crushing / vibration instrument, the diameter of the vibration head is 3mm, the working frequency is 20KHz / 10W, ultrasonic Disperse for 10-30 minutes, mix well, then add 0.4 parts by mass of amine-based surfactant N—(2-hydroxyethyl)ethylenediamine, continue ultrasonic dispersion for 12-24 hours, stop until the gel strength is 1-2 g / cm, The in-situ activation of the nanoparticles is completed to obtain a weakly gelled oil phase suspension.

[0159] Step two, emulsification.

[0160] Take the weak gel state oil phase suspension in step 1, slowly add 20 parts by mass of 0.5g / mL calcium chloride aqueous solution as the water phase emulsification, use an ultrasonic cell breaker / vibrator, the diameter of the vibration head is 3mm, and the working frequency is 20KHz / 10W , the emulsification time is 10-30min. After the emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com