Anti-wear and anti-corrosion surface coating material and preparation method thereof

A surface coating, corrosion-resistant technology, applied in the field of materials, can solve the problems of easy cracking and peeling, poor wear resistance and corrosion resistance, easy to generate air bubbles, etc. The effect of improving performance and enhancing wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

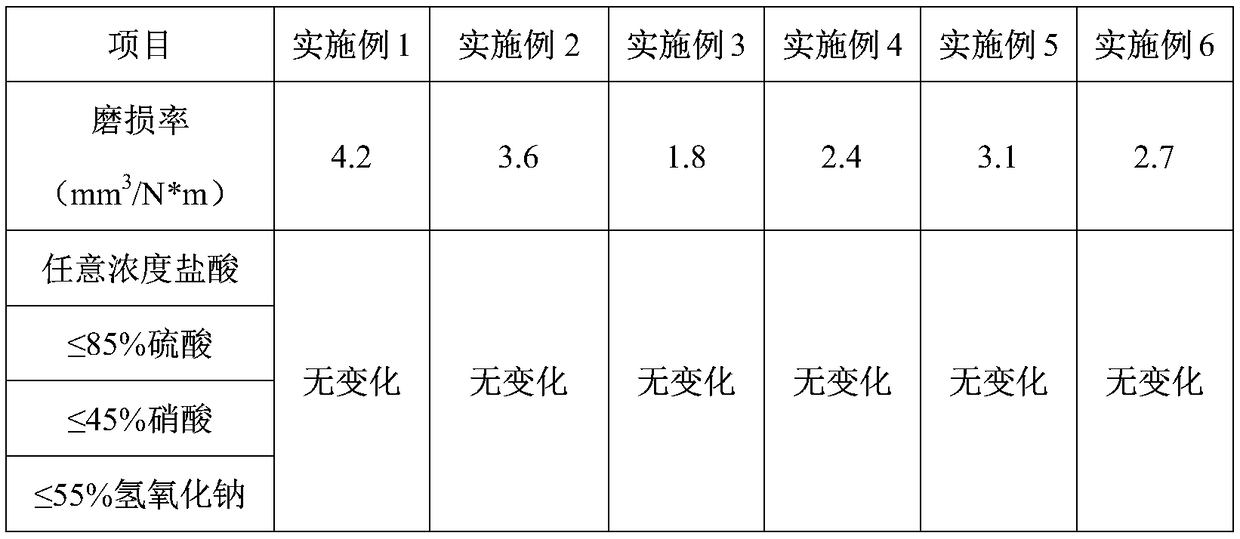

Examples

Embodiment 1

[0018] A wear-resistant and corrosion-resistant surface coating material, comprising the following components in parts by weight: 22 parts of epoxy resin, 6 parts of acrylic resin, 5 parts of tetraethyl orthosilicate, 6 parts of N-ethyl p-toluenesulfonamide, 3 parts of nano-magnesium oxide, 5 parts of monobutyl maleate, 10 parts of isophorone diisocyanate, 2 parts of curing agent, and 1 part of calcium aluminate cement.

[0019] A method for preparing a wear-resistant and corrosion-resistant surface coating material, comprising the following steps:

[0020] The first step, take by weight 22 parts of epoxy resins, 6 parts of acrylic resins, 5 parts of ethyl orthosilicate, 6 parts of N-ethyl p-toluenesulfonamide, 3 parts of nano-magnesium oxide, 5 parts of horse Monobutyl acetate, 10 parts of isophorone diisocyanate, 2 parts of curing agent and 1 part of calcium aluminate cement, spare;

[0021] The second step is to take epoxy resin, acrylic resin, N-ethyl-p-toluenesulfonamide...

Embodiment 2

[0025] A wear-resistant and corrosion-resistant surface coating material, comprising the following components in parts by weight: 35 parts of epoxy resin, 12 parts of acrylic resin, 10 parts of ethyl orthosilicate, 11 parts of N-ethyl-p-toluenesulfonamide, 6 parts of nano-magnesium oxide, 11 parts of monobutyl maleate, 25 parts of isophorone diisocyanate, 5 parts of curing agent, and 4 parts of calcium aluminate cement.

[0026] A method for preparing a wear-resistant and corrosion-resistant surface coating material, comprising the following steps:

[0027] The first step, take by weight 35 parts of epoxy resin, 12 parts of acrylic resin, 10 parts of ethyl orthosilicate, 11 parts of N-ethyl p-toluenesulfonamide, 6 parts of nano-magnesium oxide, 11 parts of horse Monobutyl mate, 25 parts of isophorone diisocyanate, 5 parts of curing agent and 4 parts of calcium aluminate cement, spare;

[0028] The second step is to take epoxy resin, acrylic resin, N-ethyl-p-toluenesulfonamide...

Embodiment 3

[0032] A wear-resistant and corrosion-resistant surface coating material, comprising the following components in parts by weight: 30 parts of epoxy resin, 8 parts of acrylic resin, 7 parts of tetraethyl orthosilicate, 9 parts of N-ethyl-p-toluenesulfonamide, 5 parts of nano magnesium oxide, 9 parts of monobutyl maleate, 20 parts of isophorone diisocyanate, 4 parts of curing agent, 2 parts of calcium aluminate cement.

[0033] A method for preparing a wear-resistant and corrosion-resistant surface coating material, comprising the following steps:

[0034] The first step, take by weight 30 parts of epoxy resin, 8 parts of acrylic resin, 7 parts of tetraethyl orthosilicate, 9 parts of N-ethyl p-toluenesulfonamide, 5 parts of nano-magnesium oxide, 9 parts of horse Monobutyl mate, 20 parts of isophorone diisocyanate, 4 parts of curing agent and 2 parts of calcium aluminate cement, spare;

[0035] The second step is to take epoxy resin, acrylic resin, N-ethyl-p-toluenesulfonamide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com