Method for preparing hydrophobic porous cordierite ceramic membrane for desalination from high-silicon industrial solid waste as raw material at low cost

A solid waste and ceramic membrane technology, applied in the field of desalination, can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

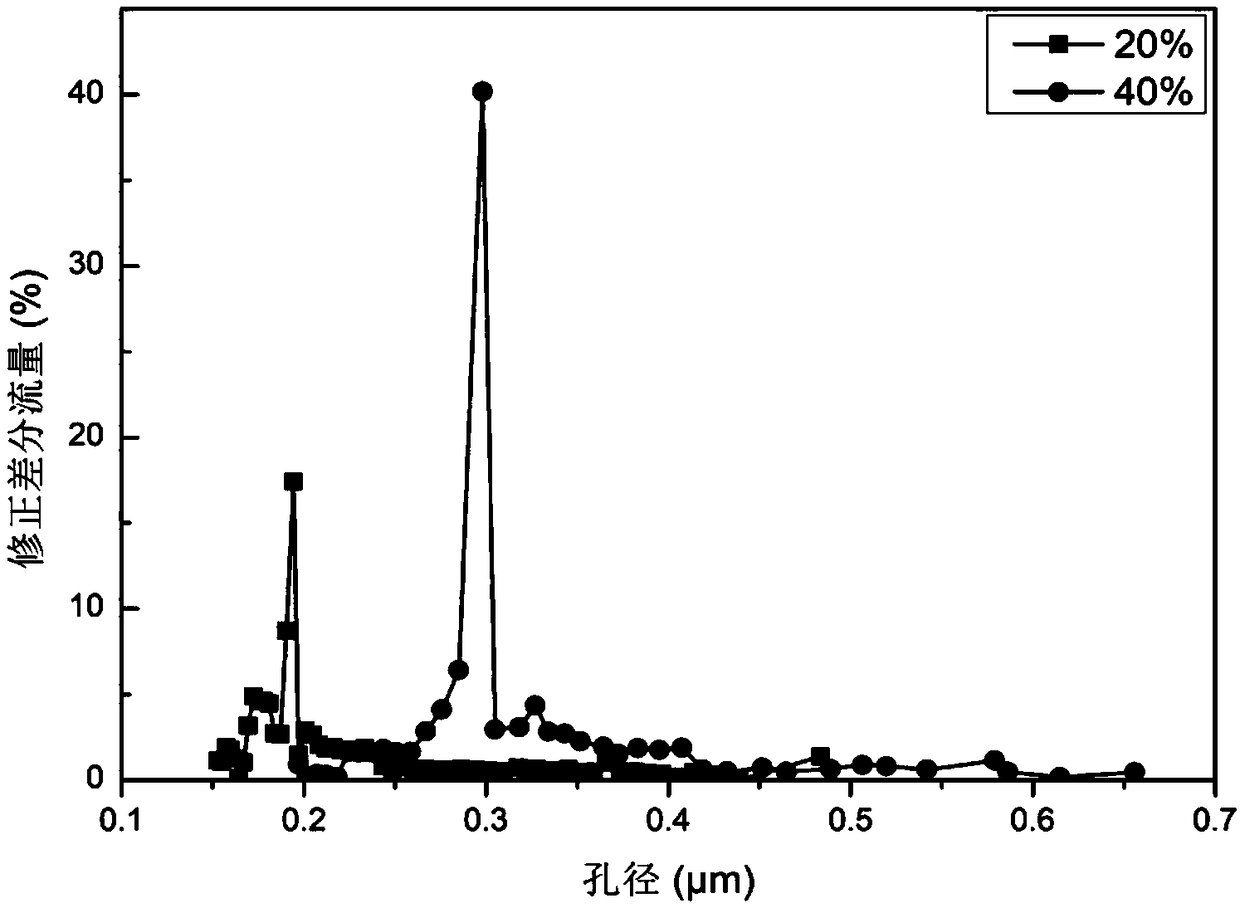

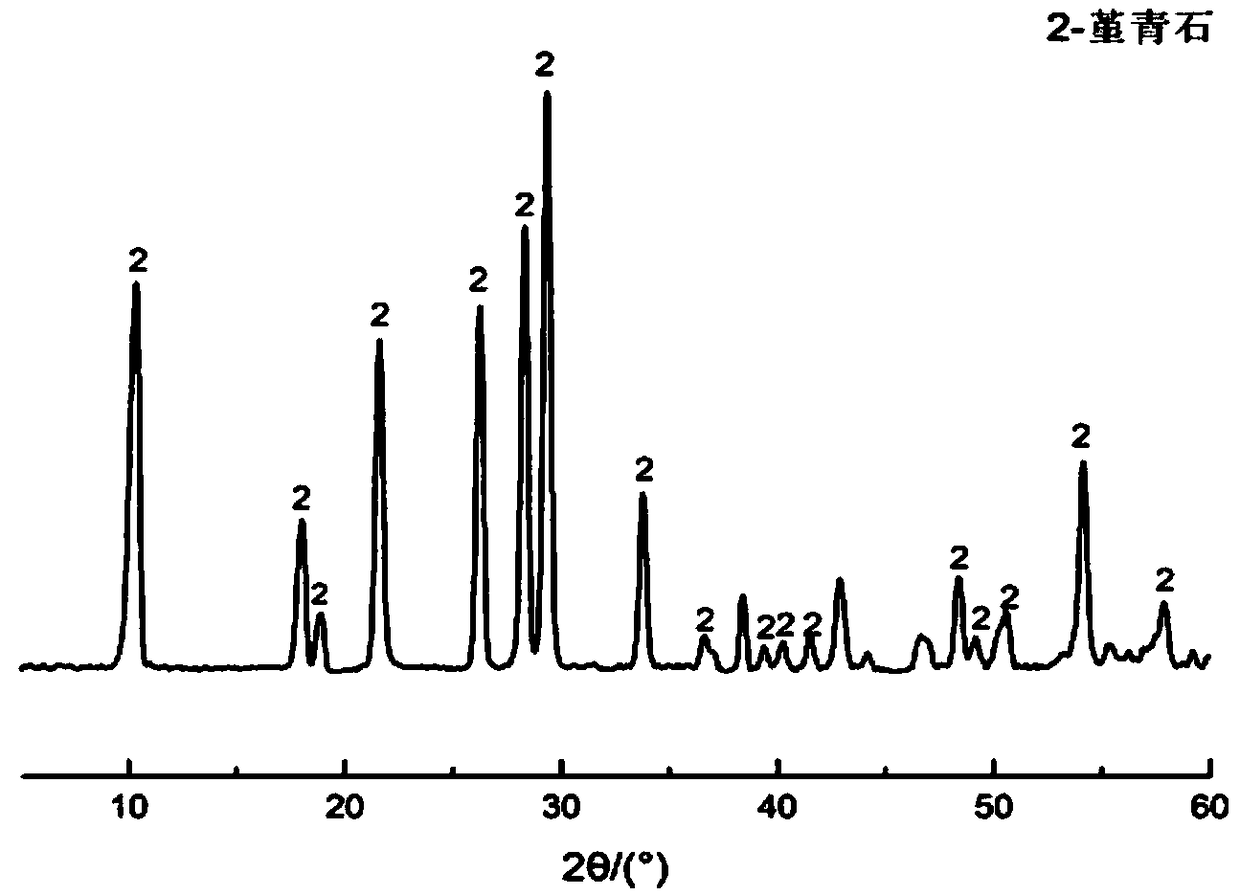

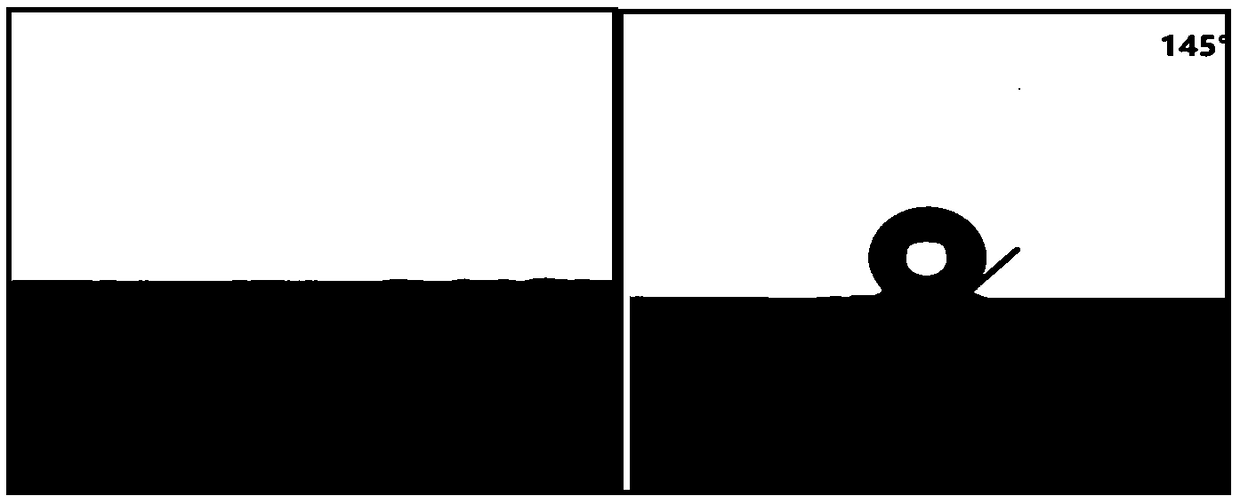

[0030] The solid waste was washed 15 times with distilled water and dried at 120 °C for 4 h. Take 40g of washed and dried solid waste into a muffle furnace, raise the temperature to 540°C for activation for one hour, and take 20g of Mg(OH) 2 , 20gAlO 3 , 20g of kaolin was put into a muffle furnace and heated to 900°C for activation for one hour, and 27g of solid waste was weighed after activation, 8.4g of Mg(OH) 2 , 15gAlO 3 , 9.6g of kaolin and 40g of starch were weighed and added to the ball milling irrigation together. The two symmetrical ball milling irrigations added the same amount, and 50ml of deionized water was added to each ball milling irrigation, and the ball milling was performed for 10 hours. Then put the ball-milled slurry into a beaker, put it into a drying oven at 100° C. for 24 hours, and then pulverize the dried sample and pass it through a 200-mesh standard sieve. Weigh 1.5g of the sieved powder and put it into a round grinding tool to press it into a ta...

Embodiment 2

[0032] The solid waste was washed 15 times with distilled water and dried at 120 °C for 4 h. Take 40g of washed and dried solid waste into a muffle furnace, raise the temperature to 540°C for activation for one hour, and take 20g of Mg(OH) 2 , 20gAlO 3 , 20g of kaolin was put into a muffle furnace and raised to 900°C for activation for one hour, and 36g of solid waste was weighed after activation, 11.2g of Mg(OH) 2 , 20gAlO 3 , 12.8g of kaolin, and 20g of starch were weighed and added to the ball milling irrigation together. The two symmetrical ball milling irrigations added the same amount, and 50ml of deionized water was added to each ball milling irrigation, and the ball milling was performed for 10 hours. Then the ball-milled slurry was put into a drying oven at 100° C. for 24 hours, and then the dried sample was pulverized and passed through a 200-mesh standard sieve. Weigh 1.5g of the sieved powder and put it into a round grinding tool to press it into a tablet at 20M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com