A kind of tft array substrate of flexible liquid crystal panel and manufacturing method thereof

A technology of array substrates and flexible liquid crystals, applied in nonlinear optics, instruments, semiconductor devices, etc., can solve problems such as exceeding the glass transition temperature of plastic substrates, and achieve the effect of overcoming production difficulties and simplifying production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

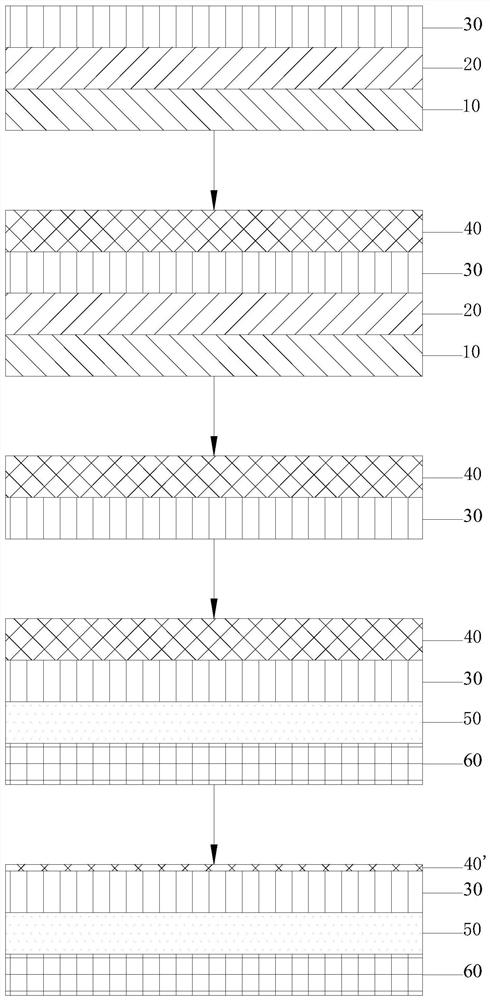

[0038] The problem to be solved by the present invention is to provide a TFT array substrate with an alignment function without a low-temperature alignment layer for a flexible liquid crystal panel and a manufacturing method thereof. The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

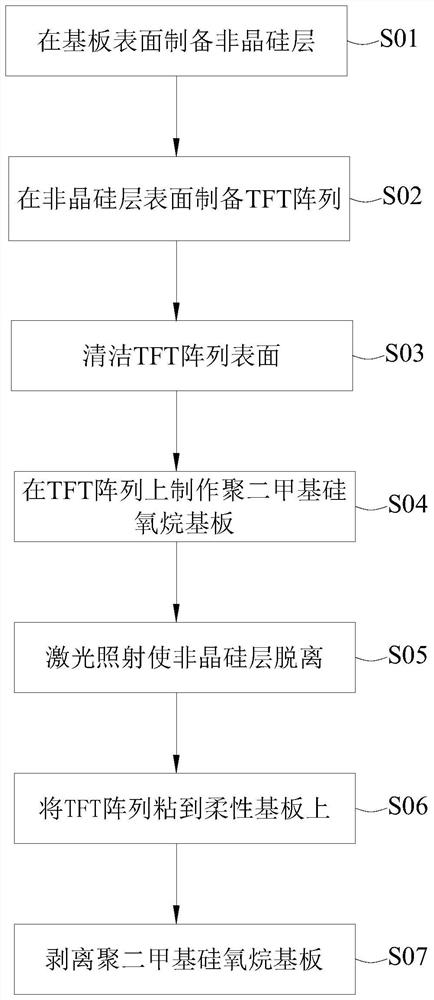

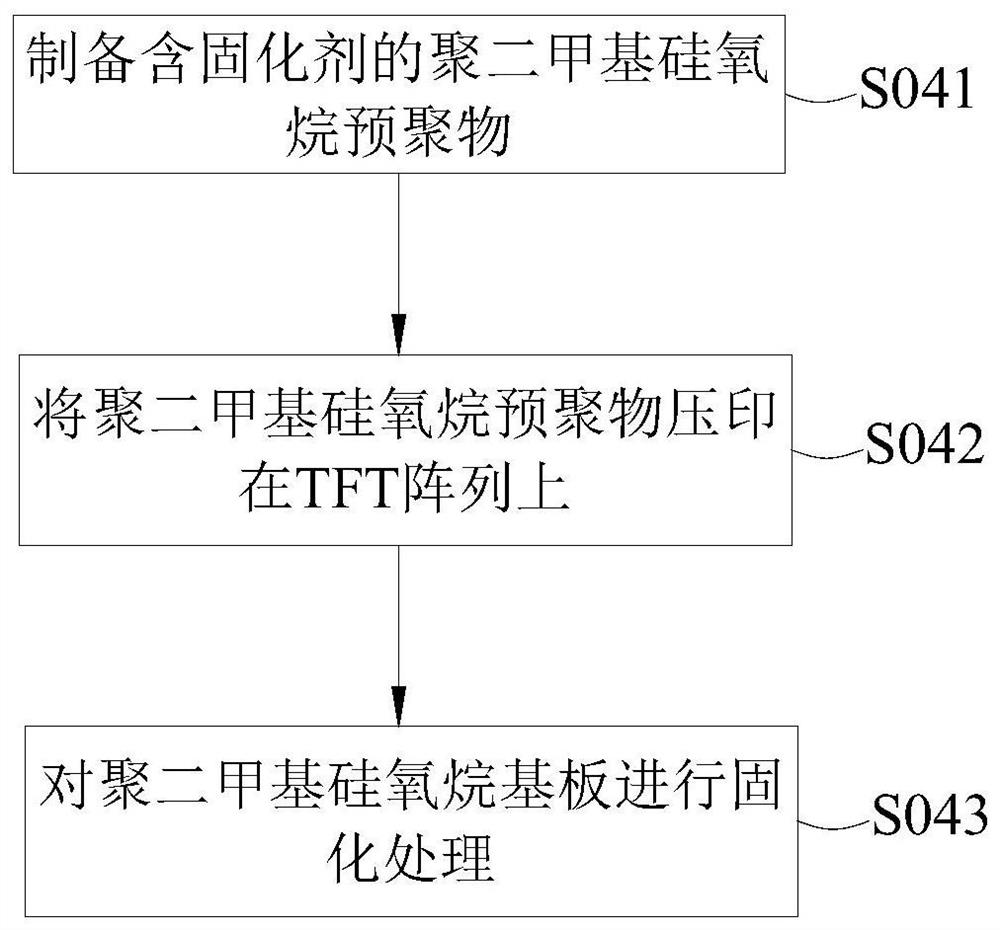

[0039] like figure 1 and image 3 As shown, a method for manufacturing a TFT array substrate of a flexible liquid crystal panel in this embodiment includes:

[0040] S01, prepare an amorphous silicon layer on the surface of the substrate; since the substrate is a rigid substrate, usually glass material can be used, in order to facilitate the separation of the TFT array and the substrate, it is necessary to first laying a layer of amorphous silicon, the amorphous silicon is amorphous silicon, and the lattice network between its atoms is arranged in disorder;

[0041] S02, preparing a TFT array on the surface of the amorphous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com