Fiber product and manufacturing method thereof

A technology of fiber products and products, applied in the field of reinforced three-dimensional composite materials, can solve the problems of high cost, limited use range, complex production process, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

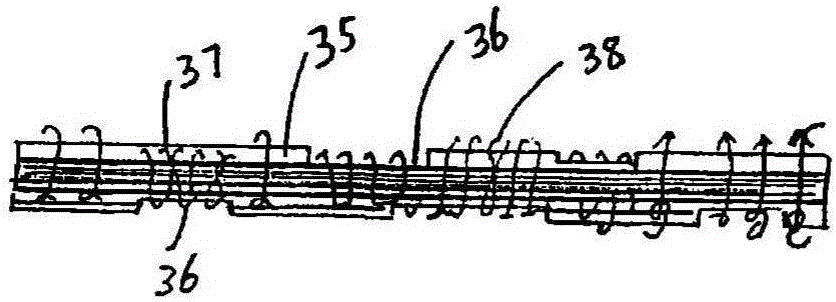

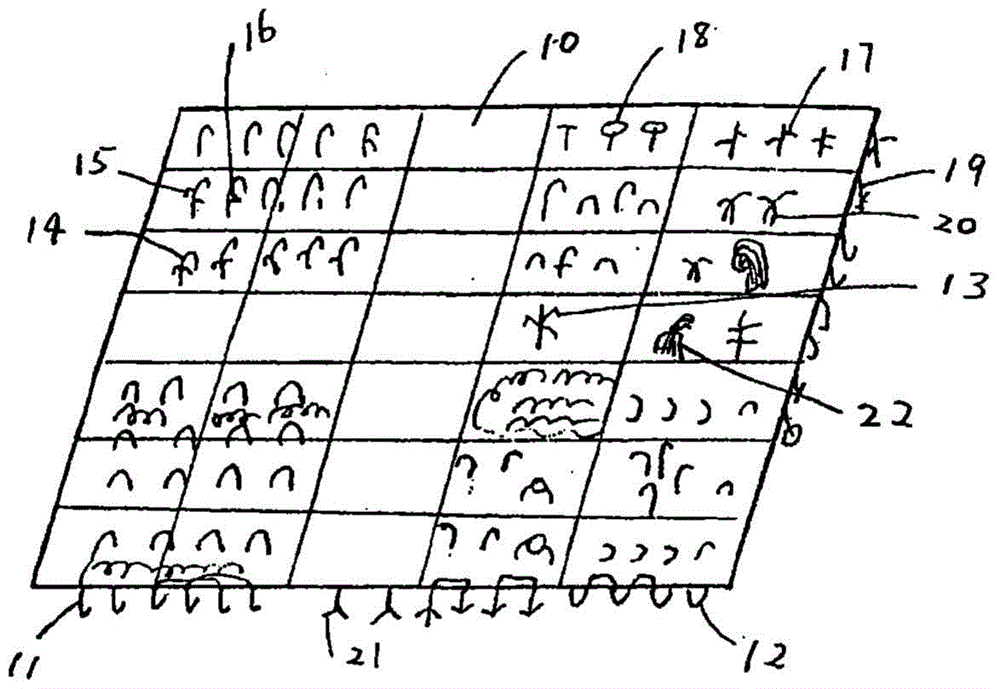

[0086] Such as figure 1 As shown, a fiber sheet or film 10 is attached with fastened connecting elements on both sides: hook 11, loop 12, anchor hook 13, fish hook 14, group hook 15, string hook 16, fork 17, big end rod 18, arrow Shape hook 19, group ring 20, cross hook 21, fiber bundle hook 22, a hook can have multiple hooks to form group hook 15, string hook 16, these connecting elements can be combined into a pattern, the array is in a specific direction in the fiber On the body, these connecting elements can be randomly distributed or mixed on the fiber body to form a fiber product.

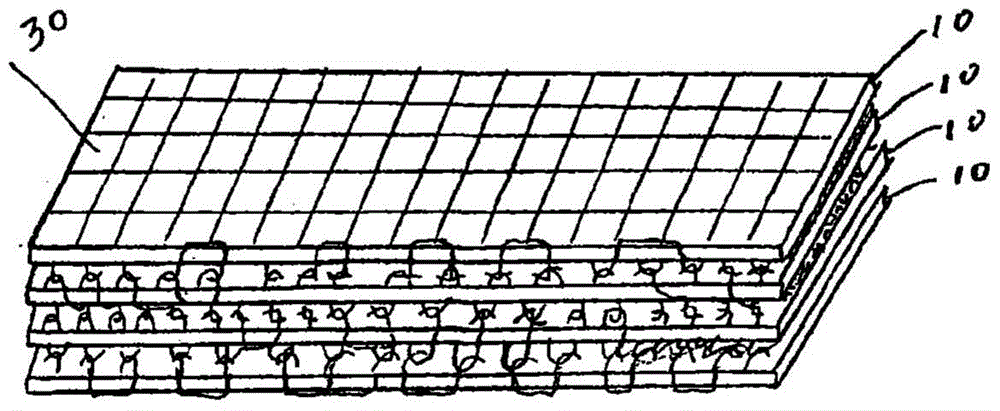

[0087] Such as figure 2 As shown, several fiber sheets 10 are stacked together to form a fiber preform 30. These hooks and loops, hooks and hooks and other connecting elements will be occluded and tied together to form reinforcing elements between the sheets. The outer sheet has Contains a hook ring on one side. The interlayer occluding binding elements make the fiber preform become a three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com