Steamed bread slice making flour modifier and use thereof

A technology of flour improver and steamed buns, which is applied in the direction of pre-baked dough processing, etc., and can solve problems not involved in the production of steamed buns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

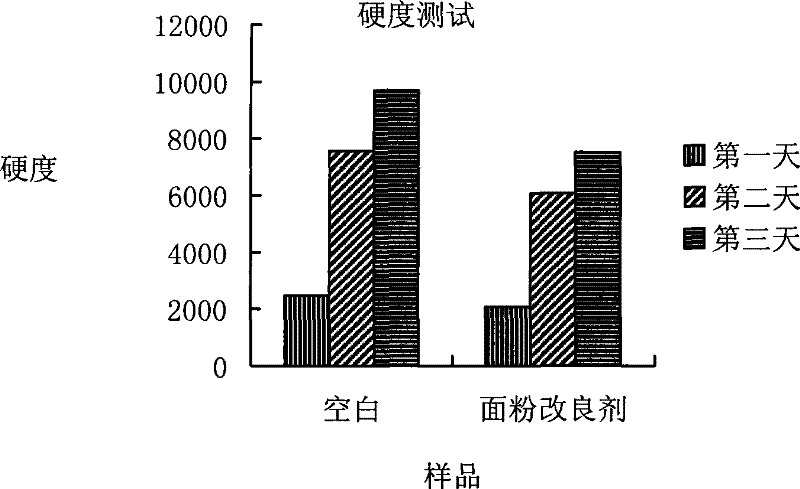

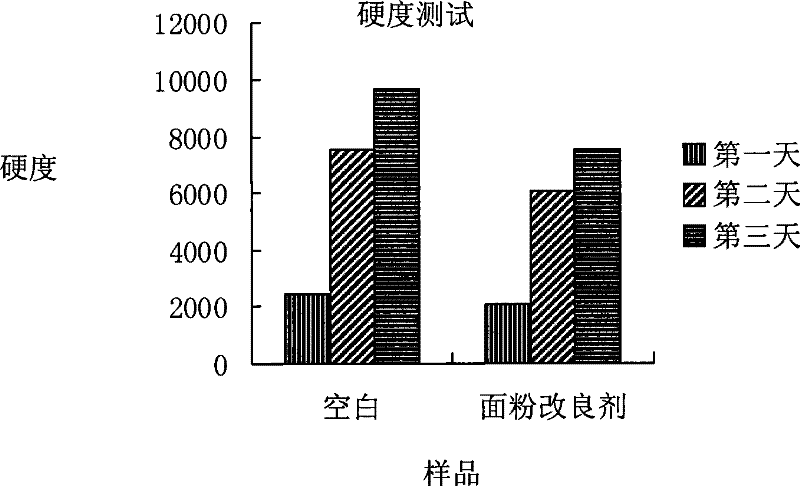

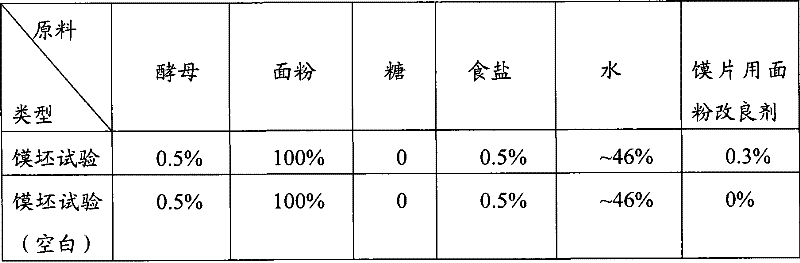

Image

Examples

Embodiment 1

[0070] Flour improver for steamed buns, the formula is as follows:

[0071] Amylase 0.1 parts by weight,

[0072] Lipase 0.1 parts by weight,

[0073] 0.3 parts by weight of xylanase,

[0074] Calcium peroxide 0.5 parts by weight,

[0075] Vitamin C 1 part by weight,

[0076] 4 parts by weight of monoglyceride,

[0077] 4 parts by weight of calcium sodium stearoyl lactylate,

[0078] Light calcium carbonate 0.5 parts by weight,

[0079] 4 parts by weight of sodium hexametaphosphate,

[0080] 8 parts by weight of sodium tripolyphosphate,

[0081] Sodium pyrophosphate 8 parts by weight, and

[0082] 20 parts by weight of cornstarch.

[0083] Weigh each raw material component according to the ratio of each raw material in the above formula, and then add each raw material component into a mixing mixer and mix evenly. After the mixing is completed, take out the raw material mixture, weigh it, and pack it separately to obtain the modifier finished product.

Embodiment 2

[0085] Flour improver for steamed buns, the formula is as follows:

[0086] 0.2 parts by weight of amylase,

[0087] 0.2 parts by weight of lipase,

[0088] 0.5 parts by weight of xylanase,

[0089] Calcium peroxide 0.8 parts by weight,

[0090] Vitamin C 1.5 parts by weight,

[0091] Monoglyceride 6 parts by weight,

[0092] 6 parts by weight of calcium sodium stearoyl lactylate,

[0093] 1 part by weight of light calcium carbonate,

[0094] Sodium hexametaphosphate 6 parts by weight,

[0095] 12 parts by weight of sodium tripolyphosphate,

[0096] Sodium pyrophosphate 12 parts by weight, and

[0097] 40 parts by weight of cornstarch.

[0098] Weigh each raw material component according to the ratio of each raw material in the above formula, and then add each raw material component into a mixing mixer and mix evenly. After the mixing is completed, take out the raw material mixture, weigh it, and pack it separately to obtain the modifier finished product.

Embodiment 3

[0100] Flour improver for steamed buns, the formula is as follows:

[0101] 0.3 parts by weight of amylase,

[0102] 0.4 parts by weight of lipase,

[0103] 0.8 parts by weight of xylanase,

[0104] Calcium peroxide 1 part by weight,

[0105] Vitamin C 2 parts by weight,

[0106] 8 parts by weight of monoglyceride,

[0107] 8 parts by weight of calcium sodium stearoyl lactylate,

[0108] Light calcium carbonate 2 parts by weight,

[0109] Sodium hexametaphosphate 7 parts by weight,

[0110] 14 parts by weight of sodium tripolyphosphate,

[0111] Sodium pyrophosphate 14 parts by weight, and

[0112] 45 parts by weight of cornstarch.

[0113] Weigh each raw material component according to the ratio of each raw material in the above formula, and then add each raw material component into a mixing mixer and mix evenly. After the mixing is completed, take out the raw material mixture, weigh it, and pack it separately to obtain the modifier finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com