Compressive stress relaxation testing device and method of rubber material

A compressive stress, rubber material technology, used in measuring devices, analyzing materials, using stable tension/pressure to test the strength of materials, etc. Complex structure and other problems, to achieve the effect of easy actual control, quick and effective judgment, and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

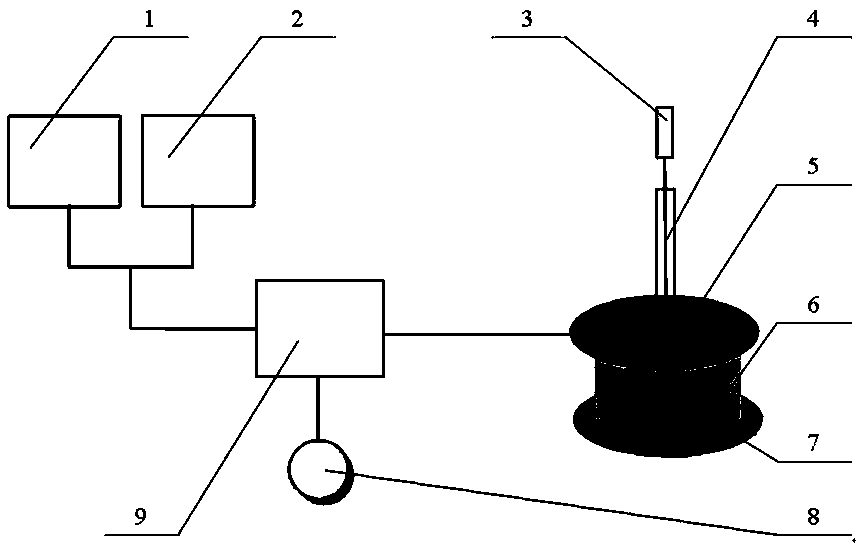

Method used

Image

Examples

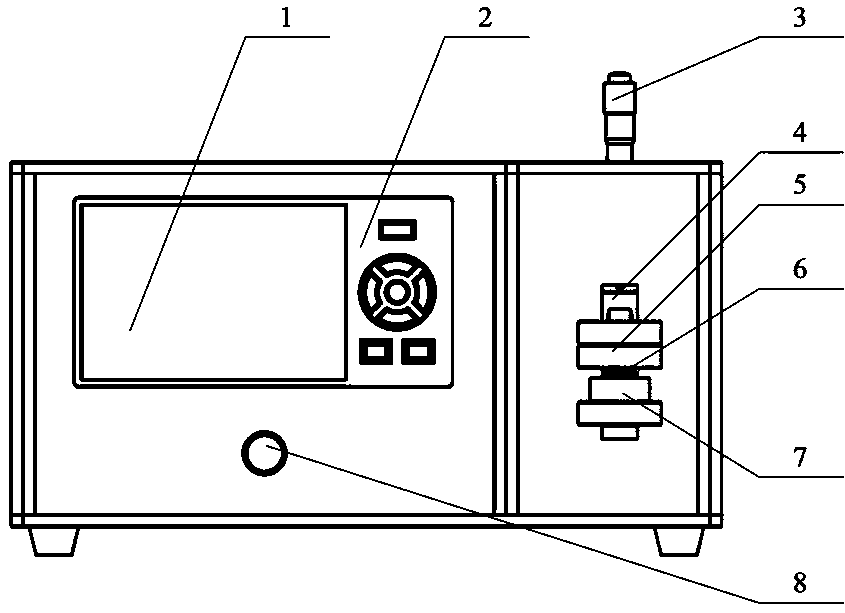

Embodiment 1

[0038] Put the sample 6 that has been cut (cut into a circle, square or rectangle, etc.) to be tested flat on the support surface of the fixed end 7 of the sample platen; turn on the power switch 8, and reset the initial compressive stress value Fa to zero ; Rotate the pressure plate movement adjustment knob 3, so that the moving end 5 of the sample pressure plate moves down along the slide rail 4 until it just touches the upper surface of the sample 6, at this time, the data display screen 1 begins to display the compressive stress data; continue to rotate the pressure plate The disc moves the adjustment knob 3 until the sample 6 is compressed to the predetermined compression amount. At this time, the compressive stress data on the data display 1 is recorded as F; after 30 minutes, the corresponding compressive stress value is recorded as F0, and F0 is the value of the sample 6 at the predetermined compression. Continue to maintain the position of the moving end 5 of the sampl...

Embodiment 2

[0040]Place the sample 6 that has been cut (cut into a circle, square or rectangle, etc.) to be tested flat on the support surface of the fixed end 7 of the sample platen; turn on the power switch 8, and record the initial compressive stress value Fa; rotate The pressure plate moves the adjustment knob 3, so that the moving end 5 of the sample pressure plate moves down along the slide rail 4 until it just touches the upper surface of the sample 6, at this time, the data display screen 1 starts to display the compressive stress data; continue to rotate the pressure plate to move Adjust the knob 3 until the sample 6 is compressed to the predetermined compression amount. At this time, the compressive stress data on the data display screen 1 is recorded as F; after 30 minutes, the corresponding compressive stress value is recorded as F0, and F0 is the sample 6 under the predetermined compression amount. Continue to maintain the position of the moving end 5 of the sample platen, and...

Embodiment 3

[0042] Place the cut circular rubber foam material sample 6 flatly on the support surface of the sample platen fixed end 7; turn on the power switch 8, and reset the initial compressive stress value Fa to zero; rotate the platen to move the adjustment knob 3. Make the moving end 5 of the sample platen move down along the slide rail 4 until it is just in contact with the upper surface of the sample 6. At this time, the data display screen 1 begins to display the compressive stress data; continue to rotate the platen movement adjustment knob 3 until Compress sample 6 to 50% of the predetermined compression amount (that is, compress the sample to 50% of the original thickness), and at this time, the compressive stress data on the data display 1 is recorded as F; after 30 minutes, the corresponding compressive stress value is recorded as F0, F0 is the initial compressive stress of the sample 6 under a predetermined amount of compression; continue to maintain the position of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com