Mold for rock-like sample containing complex joints and sample preparing method

A technology of rock samples and joints, applied in the field of rock mechanics and rock engineering, can solve the problems of cumbersome methods, inconvenient rotation operation, limited number of inclined guide chute, etc., achieve simple mold structure, improve production efficiency, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

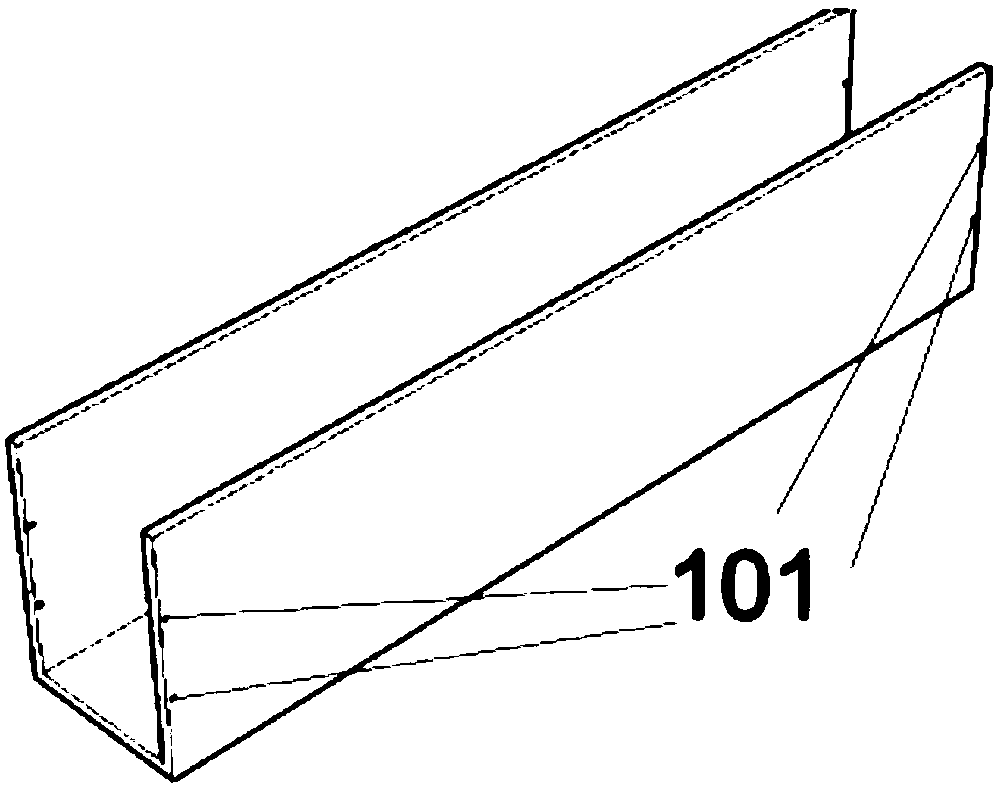

[0050] Such as Figure 1~6 As shown, a rock-like sample mold with complex joints includes a frame body 1, a pull-out rotating disc 2, a thin insert 3, and a joint insert 4; the frame body 1 includes a bottom plate and is vertically fixed to the There are two side plates on the two long sides of the bottom plate, the thin inserts 3 are two, and the two short sides of the thin inserts 3 perpendicular to the bottom plate are connected to the side plates. 3 and the frame body 1 form five sides of a rectangular parallelepiped; the thin insert 3 is provided with a circular hole, the pull-out rotating disk 2 is two, and the pull-out rotating disk 2 includes a rotating body, The handle and the insert plate 201, the diameter of the rotating body is the same as the diameter of the circular hole, one end of the rotating body is connected with a handle, and the other end of the rotating body is connected with two parallel inserting plates 201, the The insert plate 201 passes through the c...

Embodiment 2

[0056] A rock-like sample mold with complex joints is different from Example 1 in that Figure 7 As shown, the width of the joint insert 4 decreases from one end to the other end. The joint insert 4 of this shape can be used to produce joint samples with multiple penetration rates at one time.

Embodiment 3

[0058] A rock-like sample mold with complex joints is different from Example 1 in that Figure 8 As shown, the joint insert 4 is two rectangular inserts cross-connected in a cross shape. The rotating disk is connected with two parallel insert plates 201 with a gap in the middle. Each insert plate 201 is provided with two second bolt holes 202 on both sides of the gap. The joint insert 4 is connected to the insert plate 201. One end of the parallel rectangular blade is provided with two fourth pin holes 401, and the second pin hole 202 and the fourth pin hole 401 are connected by bolts to complete the fixing of the pull-out rotating disc 2 and the joint blade 4 connection. The joint insert 4 of this shape can be used to produce samples containing cross joints. The finished rock samples of this embodiment are as Picture 11 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com