Solid-state zoom lens-based non-contact laser thickness measuring device and method

A zoom lens, non-contact technology, applied in the field of optical measurement, can solve the problems of unfavorable portable or even handheld measurement, complicated device structure and operation method, high equipment price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

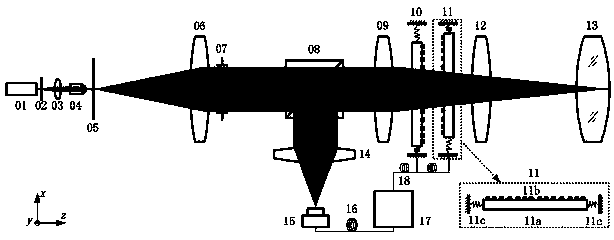

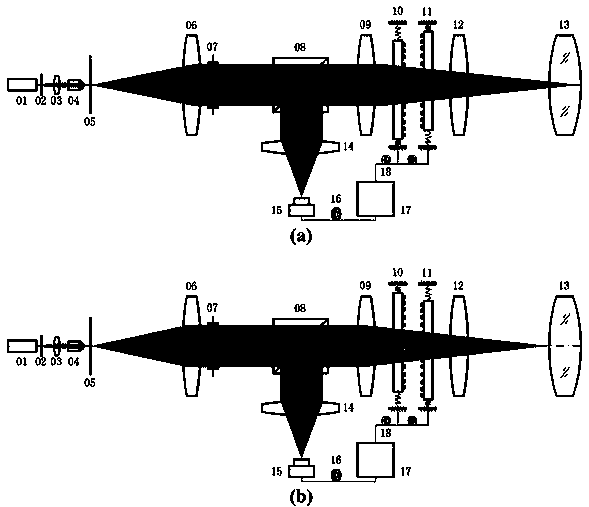

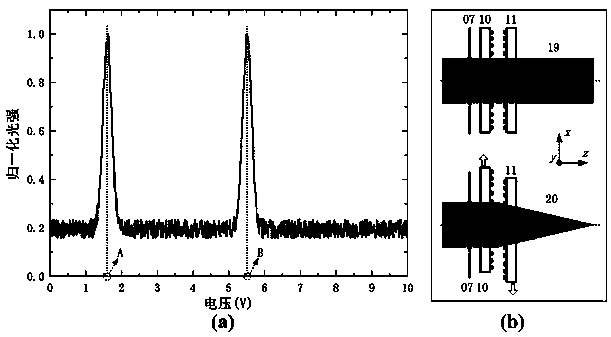

[0054] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0055] The present invention proposes a non-contact laser thickness measurement device and method based on a solid-state zoom lens, the device consists of a laser 01, an adjustable light intensity attenuator 02, a first collimator lens 03, a microlens 04, and a spatial filter 05 , the second collimator lens 06, the diaphragm 07, the dichroic prism 08, the first aberration correction lens 09, the first solid zoom lens assembly 10, the second solid zoom lens assembly 11, the second aberration correction lens 12, to be tested Object 13, focusing lens 14, photodetector 15, data transmission line 16, signal control, data processing and display module 17, and control signal transmission line 18. Take the second solid zoom lens assembly 11 as an example to illustrate the structural composition and working principle of the solid zoom lens assembly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Sampling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com