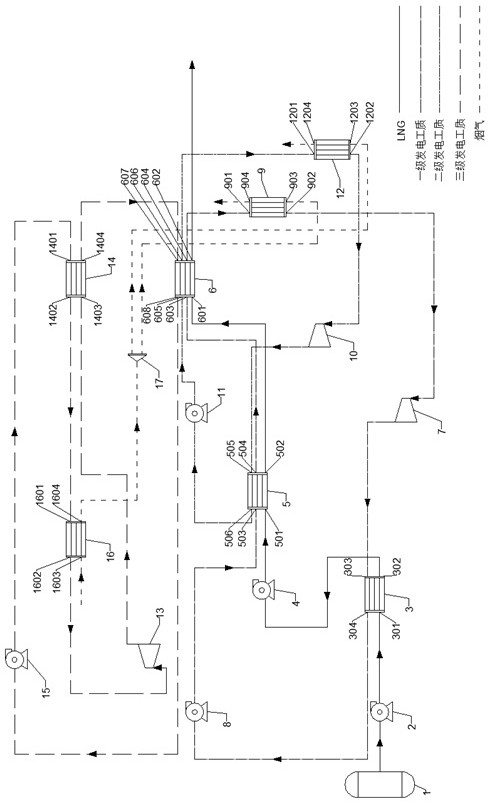

LNG power-driven ship main engine waste heat and LNG vaporization cold energy integrated utilization system

A main engine and waste heat technology, applied in the direction of charging system, engine components, combustion engine, etc., can solve the problems of high LNG pressure, increase system energy consumption, etc., achieve optimal system efficiency, reduce operating costs, compact and simple system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read this description, those skilled in the art are to the modification of various equivalent forms of this description All fall within the scope defined by the appended claims of this application.

[0022] Please combine figure 1 As shown, the integrated utilization system of the waste heat of the main engine of the LNG-powered ship in this embodiment and the cold energy of LNG vaporization includes the following five parts:

[0023] The LNG evaporation side includes an LNG storage tank 1, a first-stage LNG booster pump 2, a first-stage LNG heat exchanger 3, a second-stage LNG booster pump 4, a second-stage LNG heat exchanger 5 and The third-stage LNG heat exchanger 6, wherein the outlet of the first-stage LNG boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com