Multi-stage gas homogenizing pore plate structure and flooded evaporator for preventing suction with liquid

A flooded evaporator, plate structure technology, used in evaporator/condenser, refrigeration and liquefaction, refrigeration components, etc., can solve the problems of low gas-liquid separation efficiency, large pressure drop, long flow path, etc. And the effect of low production cost, high gas-liquid separation efficiency and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

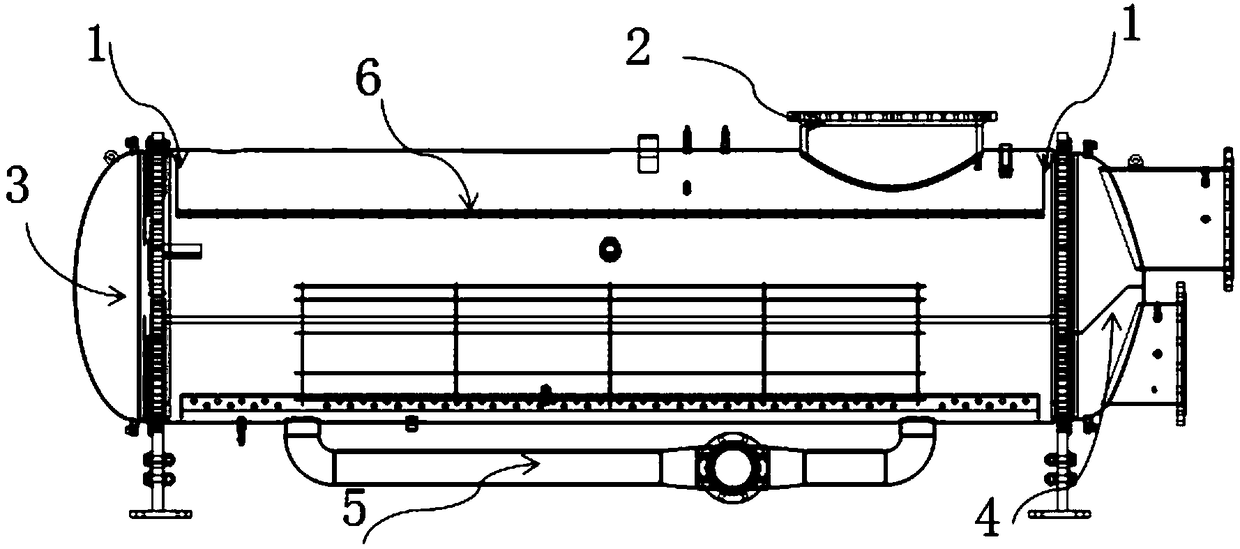

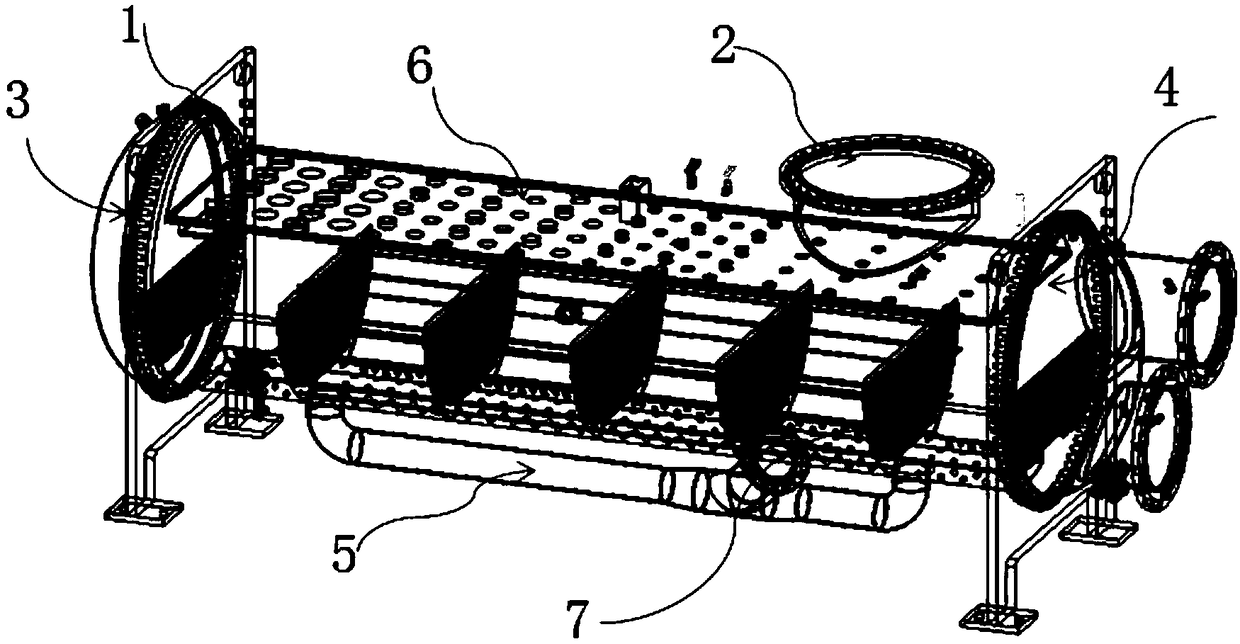

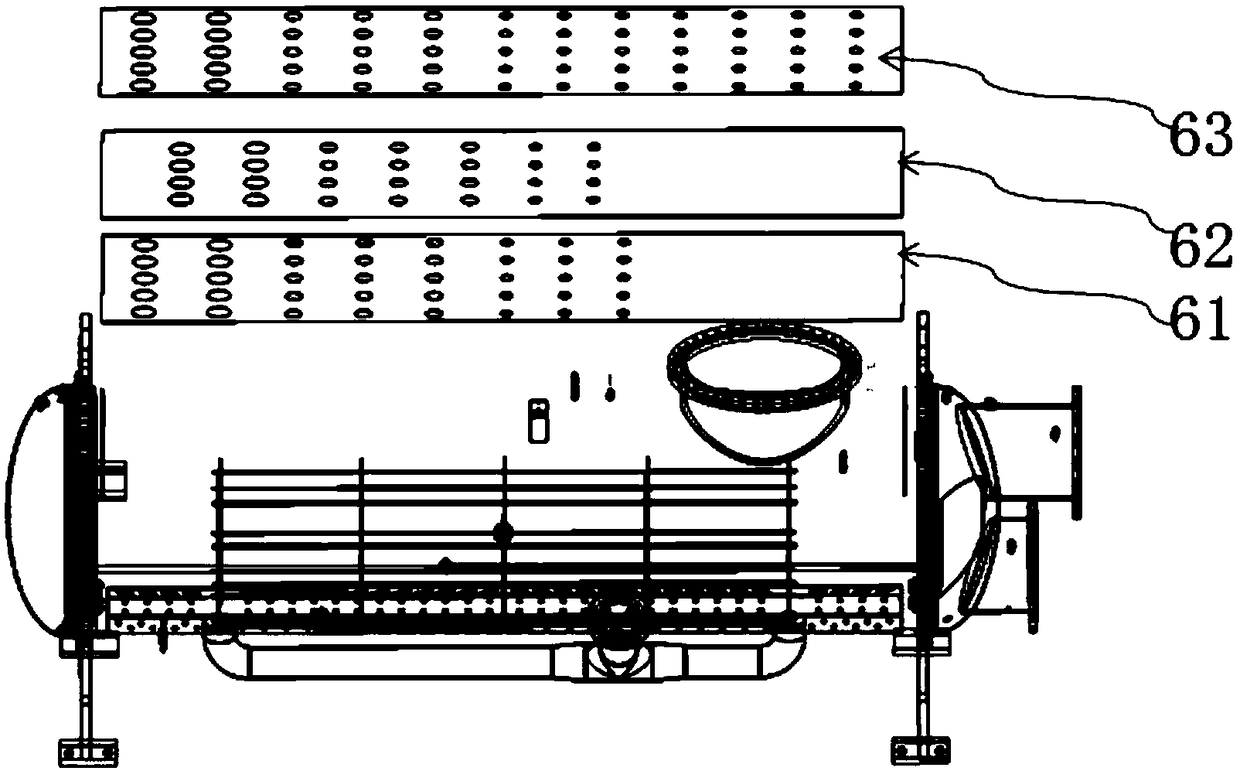

[0036] According to the present invention, the structure of the multi-stage uniform pore plate and the full-liquid evaporator that can prevent suction and liquid entrainment such as Figure 1-9 Shown.

[0037] figure 1 It is a schematic diagram of the structure of a multi-stage homogenizing orifice plate structure and a flooded evaporator with a multi-stage homogenizing orifice plate structure implemented according to the present invention. figure 2 for figure 1 Three-dimensional view of the internal structure (after removing the shell). The full-liquid evaporator is placed horizontally, and the inside of the evaporator cylinder: the multi-stage air-averaging plate structure 6 is provided with left and right air-equalizing plate baffles 1 on both sides. Below the multi-stage air-averaging plate structure 6 are multiple support plates 7 supporting and connecting the replacement Heat pipe area. A head 3 is provided on the left side of the evaporator cylinder, a cover 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com