Method for preparing gradient silicon steel thin strip through normal-temperature electro-deposition-expansion percolation and special plating solution

A technology of electrodeposition and pulse electrodeposition, applied in the field of metal surface treatment, can solve the problems of production and application constraints of silicon steel thin strip with high Si content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

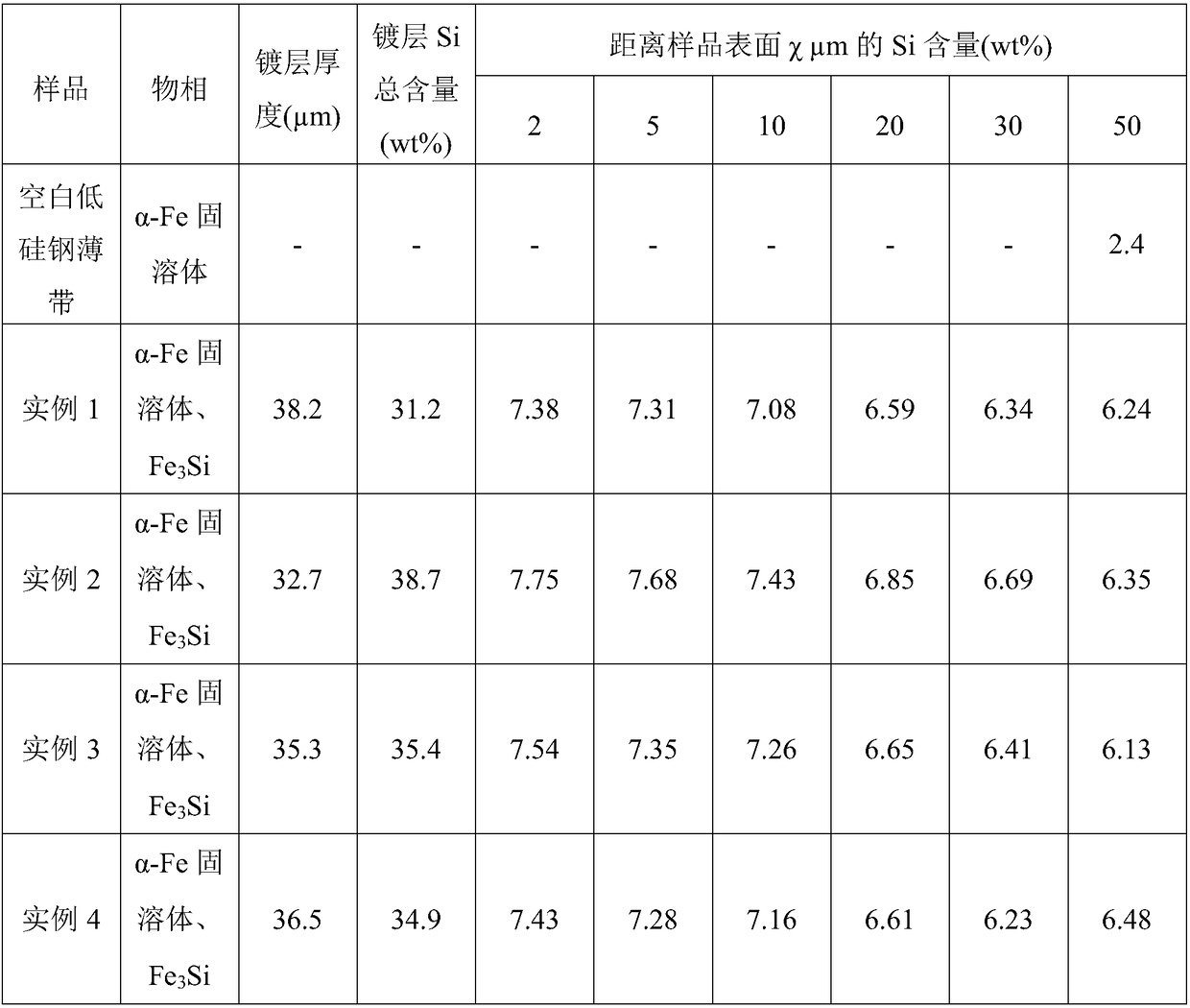

Embodiment 1

[0033] Take some low-silicon steel thin strips of 20×10×0.1mm, polish the surface with metallographic sandpaper, pickle with hydrochloric acid first, then ultrasonically clean with deionized water, absolute ethanol and acetone in sequence, dry, and put it in a desiccator for later use . The treated low-silicon steel strip will serve as a substrate for electrodeposition.

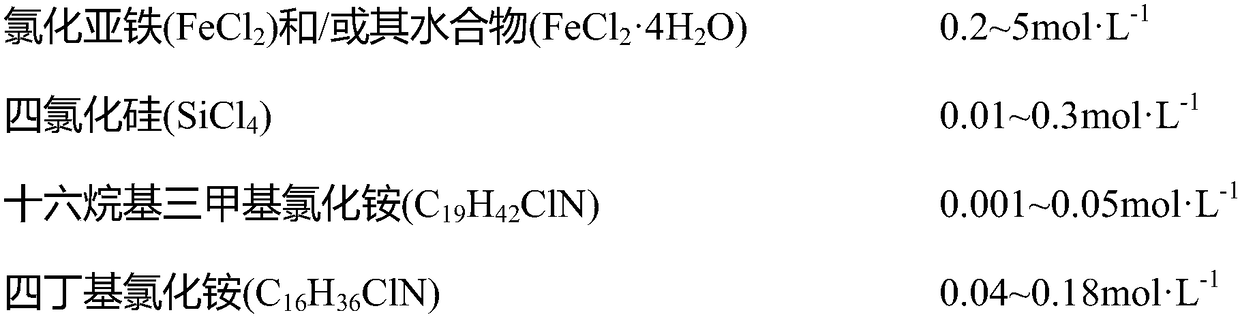

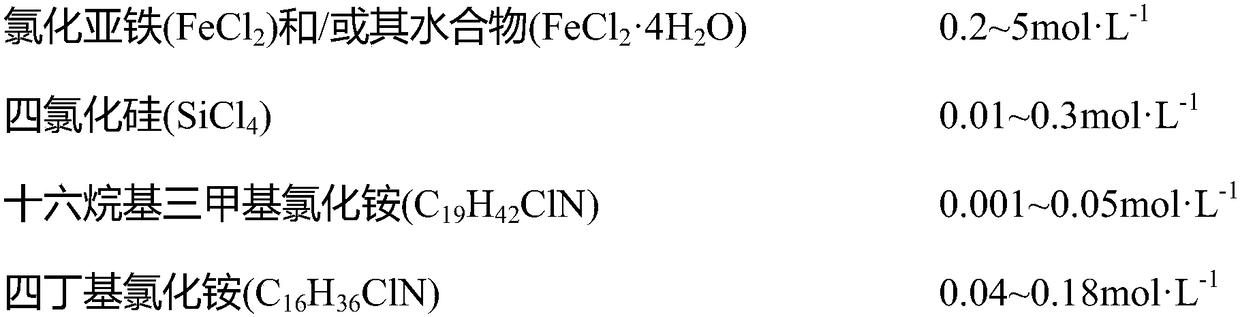

[0034] Prepare the plating solution, the composition of the plating solution is: FeCl 2 0.4mol·L -1 , SiCl 4 0.02mol·L -1 , C 19 h 42 ClN0.002mol L -1 , C 16 h 36 ClN 0.08mol L -1 , and the balance is the solvent propylene carbonate. The plating solution was left to age for 36h.

[0035] The previously pretreated low-silicon steel strip was used as the cathode, and the carbon rod was used as the anode. The distance between the cathode and the anode was 2 cm, the electrodeposition temperature was 40 ° C, and the average cathode current density was 40 mA cm -2 , the duty cycle of the pulse current i...

Embodiment 2

[0039] Process the low silicon steel thin strip according to the method of embodiment 1.

[0040] Prepare the plating solution, the composition of the plating solution is: FeCl 2 4H 2 O 0.5mol L -1 , SiCl 4 0.03mol·L -1 , C 19 h 42 ClN0.015mol L -1 , C 16 h 36 ClN 0.07mol L -1, and the balance is the solvent propylene carbonate. The plating solution was left to age for 36h.

[0041] The previously pretreated low-silicon steel strip was used as the cathode, and the carbon rod was used as the anode. The distance between the cathode and the anode was 5 cm, the electrodeposition temperature was 40 ° C, and the average cathode current density was 120 mA cm -2 , the duty cycle of the pulse current is 60%, the pulse frequency is 1200Hz, and the electrodeposition time is 10min.

[0042] The thermal expansion and infiltration treatment method is the same as in Example 1.

[0043] The analysis, characterization and performance test methods of the samples are the same as in ...

Embodiment 3

[0045] Process the low silicon steel thin strip according to the method of embodiment 1.

[0046] Prepare plating solution, and plating solution is composed with embodiment 1. The plating solution was left to age for 36h.

[0047] The previously pretreated low-silicon steel strip was used as the cathode, and the carbon rod was used as the anode. The distance between the cathode and the anode was 5 cm, and the electrodeposition temperature was 40°C.

[0048] The average cathode current density, pulse current duty ratio, pulse frequency, ultrasonic power, ultrasonic frequency, and electrodeposition time of the electrodeposition process are the same as in Example 2.

[0049] Then place the low-silicon steel strip with the Fe-Si alloy layer deposited on the surface in a reducing atmosphere furnace for thermal expansion and infiltration treatment, the atmosphere is H 2 / Ar mixed gas [V(H 2 ) / V(Ar)=8%], the heating rate is 10°C / min, the heat treatment temperature is 1000°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com