Preparation method of composite biological liquid detergent containing sodium p-toluenesulfonate

A technology of sodium p-toluenesulfonate and detergent, which is applied in the field of preparation of compound biological detergent, can solve problems such as water pollution, and achieve the effect of accelerating the adsorption of oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

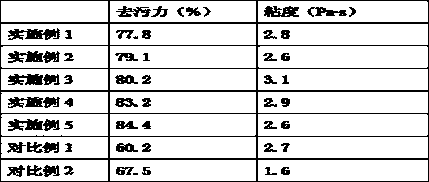

Examples

Embodiment 1

[0017] A preparation method of a compound biological detergent containing sodium p-toluenesulfonate, comprising the following steps:

[0018] S1. Cellulose powder, ammonium persulfate, lauryl methacrylate, cetearyl trimethyl ammonium chloride

[0019] , Cocamine polyoxyethylene ether and dimethyl glycol acrylate are added to deionized water, among them, cellulose powder, ammonium persulfate, lauryl methacrylate, cetearyl trimethyl chloride The mass ratio of ammonium chloride, cocoamine polyoxyethylene ether and dimethyl glycol acrylate is 10:0.2:1:0.2:1:2, stir at a temperature of 60°C for 60min, drop in a terminating reagent to terminate the reaction and remove Unreacted monomers are washed and dried to obtain modified cellulose powder;

[0020] S2. Add starch to a buffer solution of disodium hydrogen phosphate and citric acid with a pH of 5, configure a starch solution with a concentration of 30wt%, heat it in a water bath at 40°C, then add 2wt% glucoamylase, react for 10 h...

Embodiment 2

[0026] A preparation method of a compound biological detergent containing sodium p-toluenesulfonate, comprising the following steps:

[0027] S1. Cellulose powder, ammonium persulfate, lauryl methacrylate, cetearyl trimethyl ammonium chloride

[0028] , Cocamine polyoxyethylene ether and dimethyl glycol acrylate are added to deionized water, among them, cellulose powder, ammonium persulfate, lauryl methacrylate, cetearyl trimethyl chloride The mass ratio of ammonium chloride, cocoamine polyoxyethylene ether and dimethyl glycol acrylate is 10:0.5:0.5:0.8:2:1, stirred at a temperature of 100°C for 30min, and dropped into a termination reagent to terminate the reaction and remove Unreacted monomers are washed and dried to obtain modified cellulose powder;

[0029] S2. Add starch to a buffer solution of disodium hydrogen phosphate and citric acid with a pH of 5, configure a starch solution with a concentration of 40wt%, heat it in a water bath at 50°C, then add 1wt% glucoamylase,...

Embodiment 3

[0035] A preparation method of a compound biological detergent containing sodium p-toluenesulfonate, comprising the following steps:

[0036] S1. Cellulose powder, ammonium persulfate, lauryl methacrylate, cetearyl trimethyl ammonium chloride

[0037] , Cocamine polyoxyethylene ether and dimethyl glycol acrylate are added to deionized water, of which, ammonium persulfate, lauryl methacrylate, cetearyl trimethyl ammonium chloride, coconut The mass ratio of oleylamine polyoxyethylene ether to dimethyl glycol acrylate is 10:0.3:0.8:0.4:2:1, stirred at a temperature of 60°C for 60 minutes, and dropped into a termination reagent to terminate the reaction to remove unreacted mono body, washed and dried to obtain modified cellulose powder;

[0038] S2. Add starch to a buffer solution of disodium hydrogen phosphate and citric acid with a pH of 5, configure a starch solution with a concentration of 40wt%, heat it in a water bath at 50°C, then add 1wt% glucoamylase, react for 15 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com