Light-weight reinforced gypsum plaster board and preparation method thereof

A paper surface gypsum board, gypsum board technology, applied in the field of gypsum board for construction, can solve the problems of increasing production, transportation and construction costs, increasing the quality of board per unit area, wasting resources, etc., to improve the strength and bonding performance, improve The effect of damp bonding quality and improving the workability of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

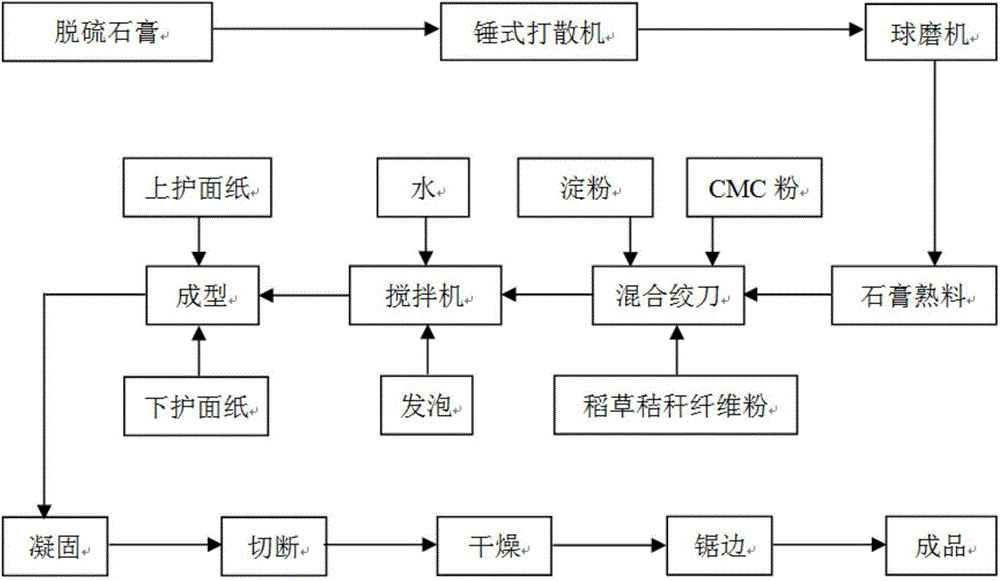

Method used

Image

Examples

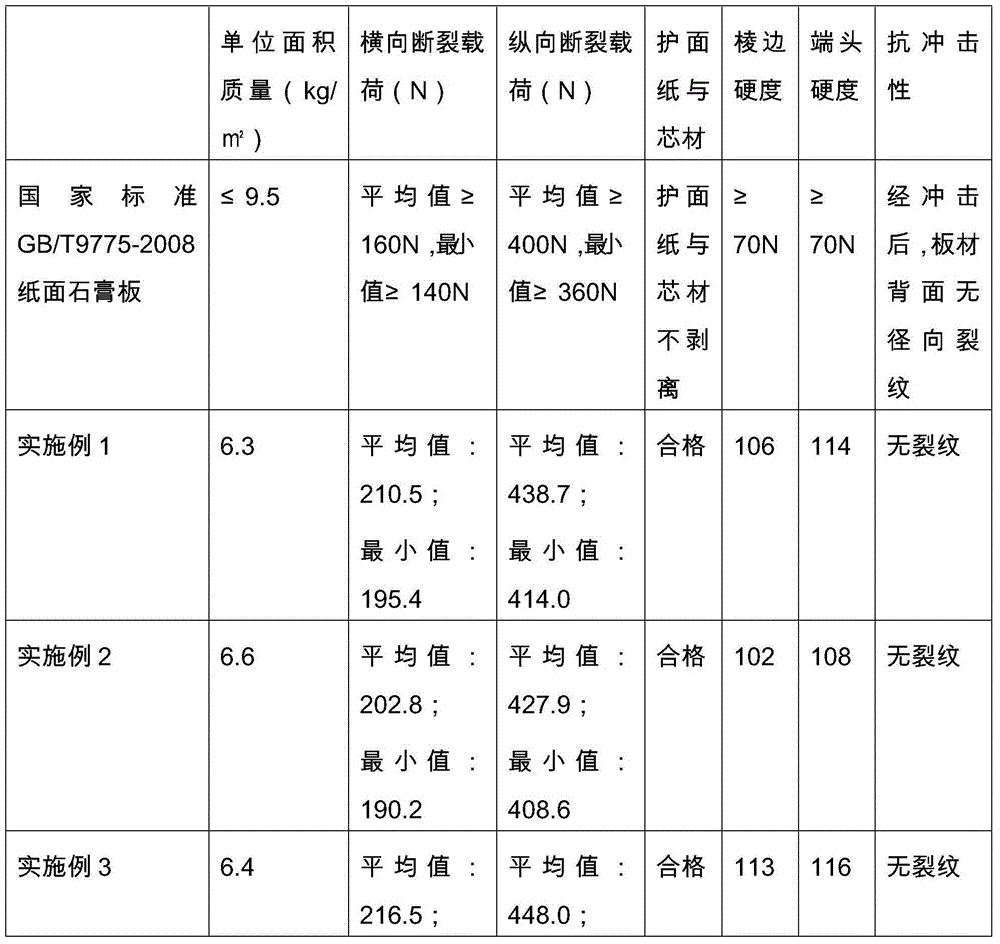

Embodiment 1

[0034] Weigh each raw material according to the following parts by weight: gypsum clinker: 100 parts; modified starch: 1 part; foaming agent: 0.1 part; rice straw fiber powder: 8 parts; CMC powder: 0.5 part; water: 80 parts .

[0035] Prepare lightweight reinforced gypsum board as follows:

[0036] 1) Add the gypsum clinker and rice straw fiber powder to the mixing reamer and mix thoroughly, then enter the mixer, then add the CMC powder and modified starch to the mixer in turn, and continue to stir evenly;

[0037] 2) The blowing agent is mixed with part of the water, the weight of the blowing agent is 1.2% of the weight of the water, and the blowing agent solution is foamed through the foaming system, and then also enters the mixer;

[0038] 3) The raw materials are fully stirred in the mixer to obtain a uniform slurry, which is continuously poured between two layers of cardboard and extruded to obtain a wet gypsum board;

[0039] 4) The wet gypsum board is solidified, cut,...

Embodiment 2

[0041] Weigh each raw material according to the following parts by weight: gypsum clinker: 100 parts; modified starch: 0.2 part; foaming agent: 0.02 part; rice straw fiber powder: 5 parts; CMC powder: 0.1 part; water: 60 parts .

[0042] Prepare lightweight reinforced gypsum board as follows:

[0043] 1) Add the gypsum clinker and rice straw fiber powder to the mixing reamer and mix thoroughly, then enter the mixer, then add the CMC powder and modified starch to the mixer in turn, and continue to stir evenly;

[0044] 2) The blowing agent is mixed with part of the water, the weight of the blowing agent is 1.2% of the weight of the water, and the blowing agent solution is foamed through the foaming system, and then also enters the mixer;

[0045] 3) The raw materials are fully stirred in the mixer to obtain a uniform slurry, which is continuously poured between two layers of cardboard and extruded to obtain a wet gypsum board;

[0046]4) The wet gypsum board is solidified, cu...

Embodiment 3

[0048] Weigh each raw material according to the following parts by weight: gypsum clinker: 100 parts; modified starch: 0.5 parts; foaming agent: 0.04 parts; rice straw fiber powder: 8 parts; CMC powder: 0.2 parts; water: 75 parts .

[0049] Prepare lightweight reinforced gypsum board as follows:

[0050] 1) Add the gypsum clinker and rice straw fiber powder to the mixing reamer and mix thoroughly, then enter the mixer, then add the CMC powder and modified starch to the mixer in turn, and continue to stir evenly;

[0051] 2) The blowing agent is mixed with part of the water, the weight of the blowing agent is 1.2% of the weight of the water, and the blowing agent solution is foamed through the foaming system, and then also enters the mixer;

[0052] 3) The raw materials are fully stirred in the mixer to obtain a uniform slurry, which is continuously poured between two layers of cardboard and extruded to obtain a wet gypsum board;

[0053] 4) The wet gypsum board is solidified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com