Ultraviolet protection hydrophobic coating agent and preparation method thereof and application thereof

A hydrophobic coating, anti-ultraviolet technology, applied in the field of hydrophobic coating agent, anti-ultraviolet hydrophobic coating agent, can solve the problem of no configuration, affecting the safety of driving vehicles, affecting the driver's sight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] For the preparation process of the polymer, you can refer to the references for the preparation of silicone acrylic polymer emulsion, preferably "Synthesis and Particle Size Analysis of Silicone-Acrylic Polymer Emulsion", Zhang Qingxuan et al., Chemical Research and Application, Vol. 22 No. Phase 4, Section 1.2 Preparation.

[0042] (Low Molecular Weight Terminated Polydimethylsiloxane)

[0043] The low-molecular-weight hydroxyl-terminated polydimethylsiloxane of the present invention is not particularly limited, and common polydimethylsiloxanes containing terminal hydroxyl groups are suitable for use. Regarding the molecular weight, the molecular weight of the low molecular weight hydroxyl-terminated polydimethylsiloxane is preferably 500-3000, more preferably 1000-2000.

[0044] The preferred end group of the low-molecular-weight hydroxyl-terminated polydimethylsiloxane also contains an alkoxy group, which can improve the interaction with the silane structure in the ...

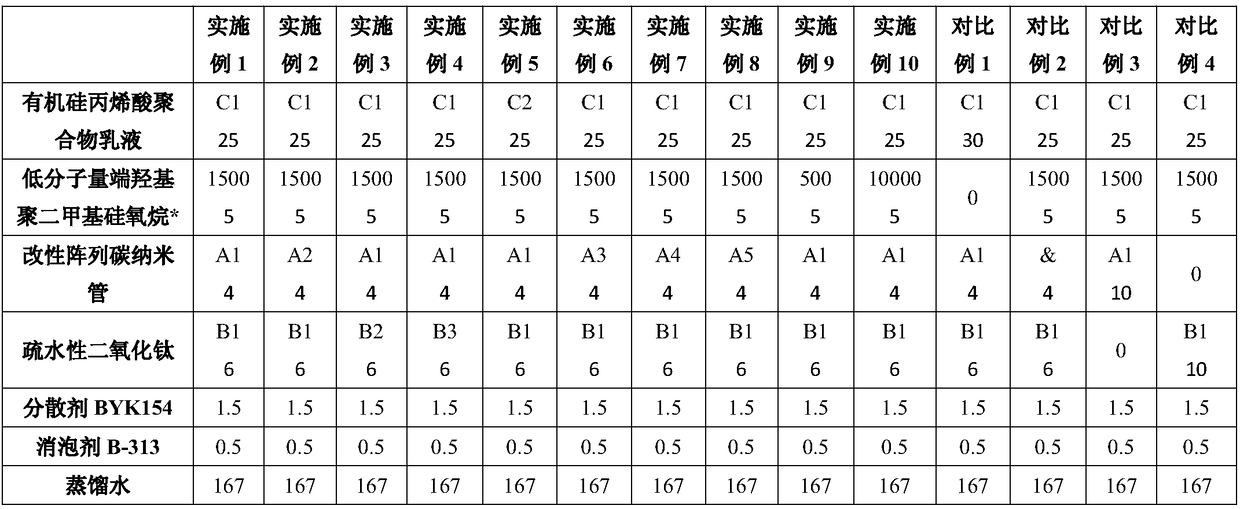

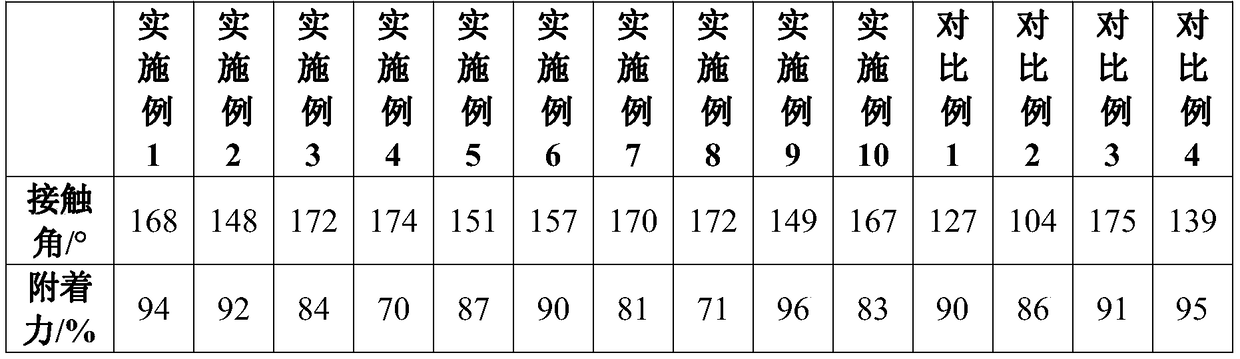

specific Embodiment approach

[0084] In order to make those skilled in the art more intuitively understand the technical solutions claimed in the present invention. Several embodiments and comparative examples are given below, but the above-mentioned embodiments and comparative examples do not constitute a limitation to the protection scope of the claims, and any concept that does not violate the present invention falls within the protection scope of the present invention.

[0085] (Preparation of modified array carbon nanotubes)

preparation example 1

[0087] (1) Carbon nanotubes are grown on a quartz substrate to form an array of carbon nanotubes, which are crushed into particles of about 1 μm;

[0088] (2) Add 100 parts by weight of the particles obtained in step (1) to a 0.05M hydrofluoric acid solution, stir for 15 minutes, and dry;

[0089] (3) Add the product of step (2) to 1.5 parts by weight of an alcoholic aqueous solution containing aminosilane coupling agent A-1100, stir for about 1 hour, and wash with water;

[0090] (4) The product of step (3) was treated with 8 parts by weight of fluorine-containing silane coupling agent heptadecafluorodecyltrimethoxysilane for about 2 hours, and dried to obtain the modified carbon nanotube array A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com