A kind of continuous production of caramel color at normal pressure and method for stabilizing the same

A steady-state, caramel-colored technology, applied in the production of caramel pigments, can solve problems such as product precipitation, difficulty in removal, and impact on product quality, and achieve low SO2 residues and solve quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The synthetic method is common method.

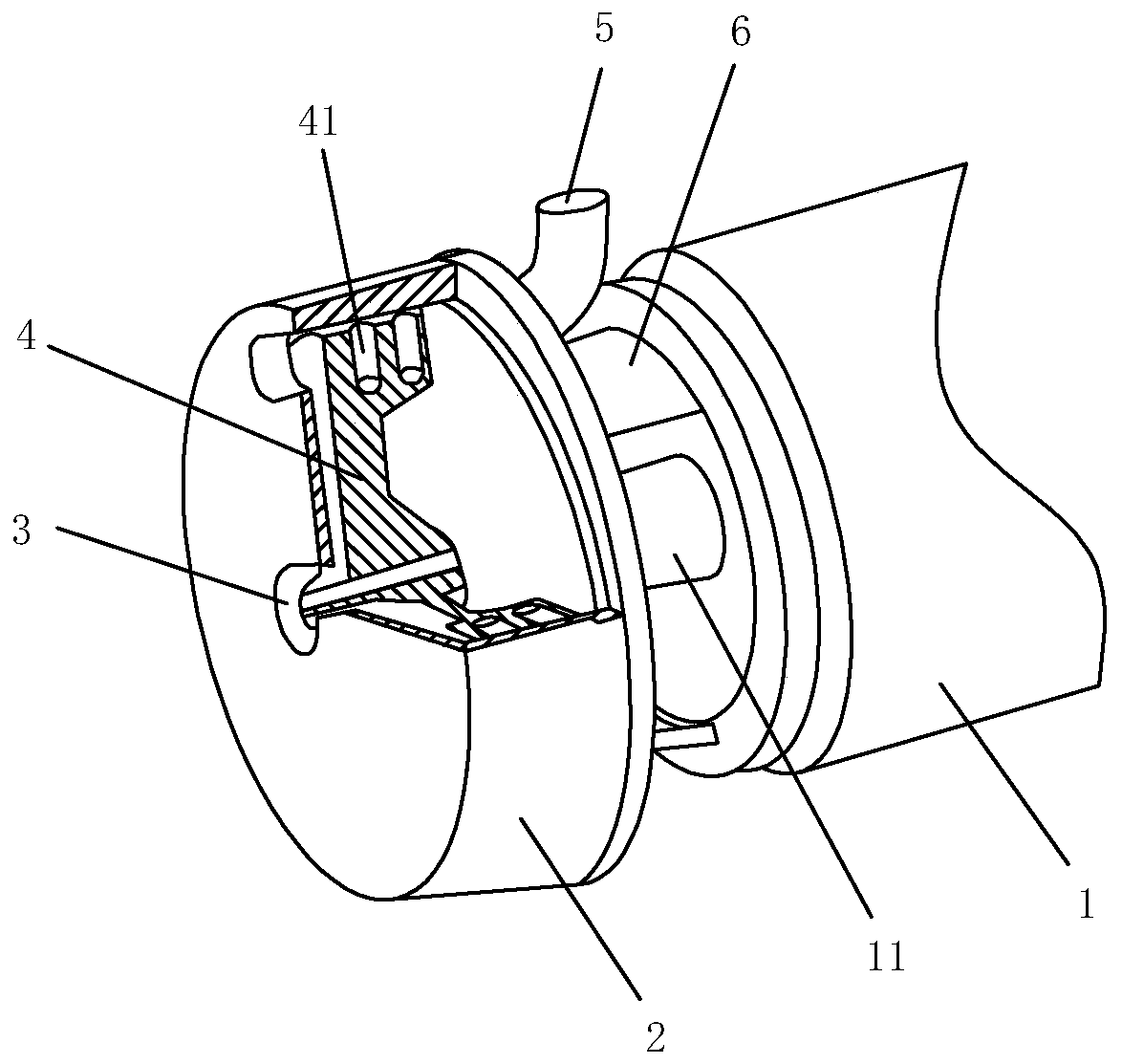

[0025] Use non-reducing sugar brown sugar as raw material, add water to prepare a 70% w / w sugar solution, heat to 90-100°C, add HCl solution with a mass concentration of 10%-35% through a pipeline mixer, and adjust the pH to 2.0-3.0 , and maintained in the laminar flow tank for 1 to 1.5 hours, adding NaOH solution with a mass concentration of 10% to 35% through the pipeline mixer at the outlet of the laminar flow tank, adjusting the pH to 8.0 to 10.0, and feeding the coke based on the principle of scraper film evaporation. In the saccharification reactor, the caramelization reactor is heated to 220-250°C with heat transfer oil, and the scraper speed and feed flow rate are adjusted so that the feed liquid stays in the reactor for 0.5h. With side stirring, when the feed liquid enters the collection tank, pour hot water at 90-100°C into the collection tank to adjust the concentration of the product to 34-36°Bé. The ro...

Embodiment 2

[0027] Embodiment 2: the synthetic method is ammonia method.

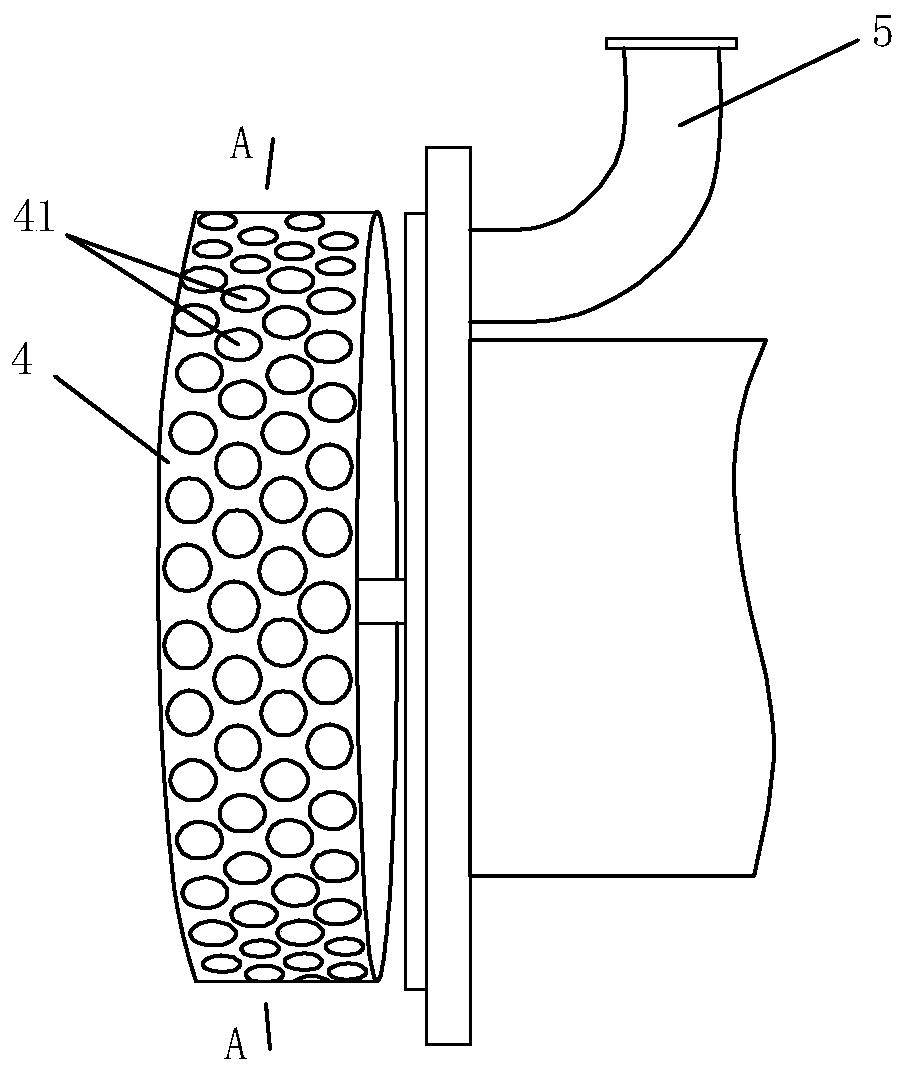

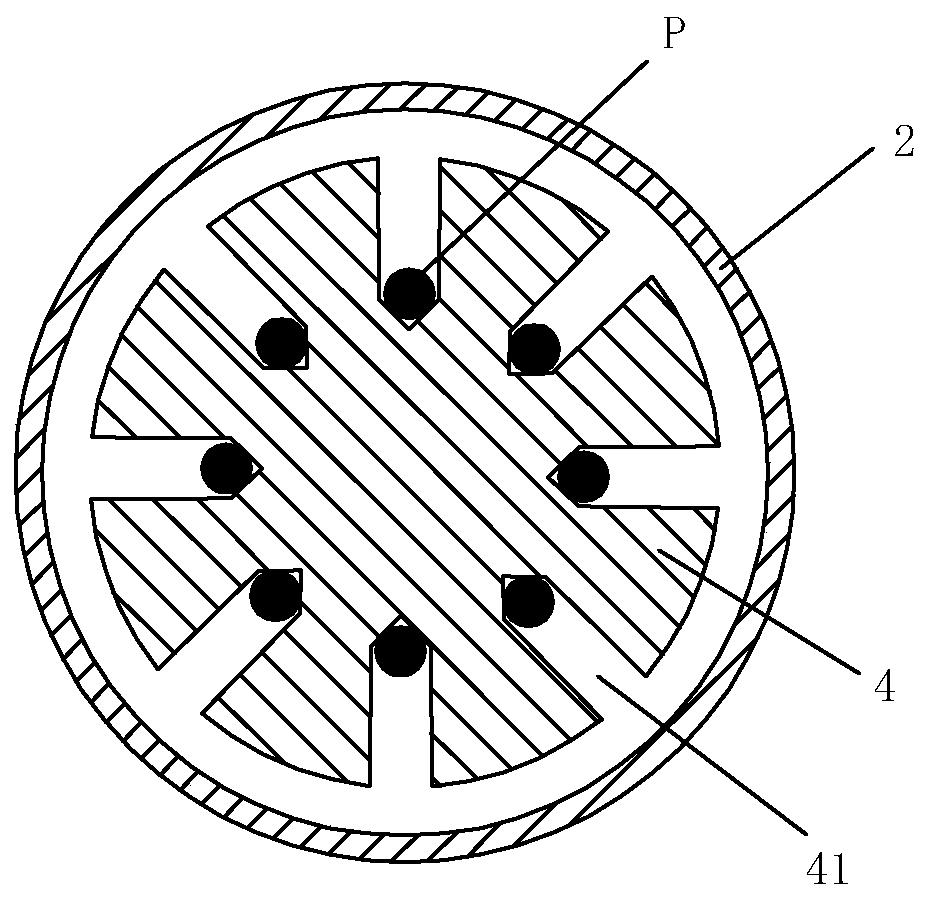

[0028] Using reducing sugar glucose as raw material, add water to prepare a 70% w / w sugar solution, heat it to 90-100°C, add ammonia water with 5% sugar solution mass through a pipeline mixer, and pass it into the caramelization reactor for caramelization reaction Heat the reactor to 160-180°C with steam, adjust the speed of the scraper and the feed flow rate so that the feed liquid stays in the reactor for 20 minutes. After the reaction is completed, the feed liquid enters the collection tank. At the same time, pour hot water at 90-100°C into the collection tank to adjust the concentration of the product to 34-36°Bé. The outlet of the collection irrigation is connected to the inlet of the colloid hydration reactor. The speed of the rotor of the colloid hydration reactor is 2950 RPM. The diameter is 20 cm, the gap between the rotor and the stator is 6 mm, the diameter of the cavitation hole on the rotor is Φ4 mm, a...

Embodiment 3

[0030] Embodiment 3: The synthesis method is the ammonium sulfite method.

[0031] Using reducing sugar glucose as raw material, add water to prepare 70% w / w sugar solution, heat to 90-100°C, add 5% ammonium sulfite solution (concentration: 30% w / w) of sugar solution through pipeline mixer , into the caramelization reactor, and the caramelization reactor is heated to 180-200°C with steam, and the scraper speed and feed flow rate are adjusted so that the feed liquid stays in the reactor for 40 minutes. After the reaction, the feed liquid enters the collection tank and is collected. The tank is equipped with side agitation. When the feed liquid enters the collection tank, pour hot water at 90-100°C into the collection tank to adjust the concentration of the product to 34-36°Bé. The rotational speed of the rotor of the hydration reactor is 2950 RPM, the diameter of the rotor is 20 cm, the gap between the rotor and the stator is 6 mm, the diameter of the cavitation hole on the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com