Galvanized frame hoisting fixture

A fixture and hoisting technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as poor hoisting and transshipment of galvanized large racks, affecting the quality of galvanized products, scratches, bumps, etc., to improve the lifting speed Efficiency and finished product quality, eliminate unsafe factors, use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

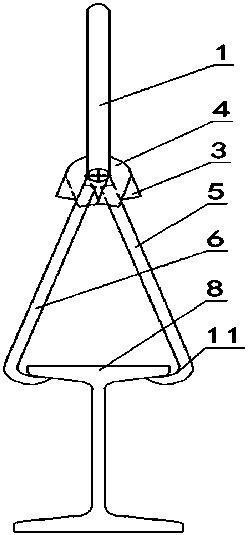

[0009] Example 1: A galvanized frame hoisting jig, the hoisting frame (1) is an equilateral trapezoidal frame, and reinforcing ribs (2) are intersected and welded in the middle so that it does not twist and deform when hoisting and rotating. The hoisting frame (1) The lower part is hinged with clamp A (5) and clamp B (6) respectively through lifting ring A (3) and lifting ring B (4), and lifting ring A (3) and lifting ring B (4) are respectively connected with clamp A (5) and Fixture B (6) is welded, and the upper parts of fixture A (5) and fixture B (6) have notch A (9) and notch B (10) corresponding to lifting ring A (3) and lifting ring B (4). ), fixture A (5) and fixture B (6) are double-sided close-fitting interlaced bite, fixture A (5) and fixture B (6) are "U"-shaped steel plates, and in the middle of the "U"-shaped steel plate The connecting plate (7) is welded, and the lower ends of fixture A (5) and fixture B (6) are relatively bent with a 40º clip angle (11), and th...

Embodiment 2

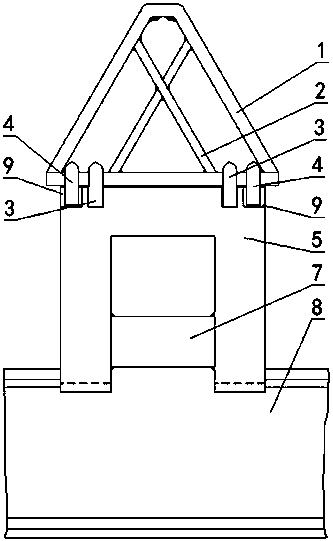

[0010] Embodiment 2: A galvanized frame hoisting jig, the hoisting frame (1) is an equilateral trapezoidal frame, and reinforcing ribs (2) are cross-welded in the middle, so that it does not twist and deform when it is hoisted, and the hoisting frame (1) The lower part is hinged with clamp A (5) and clamp B (6) respectively through lifting ring A (3) and lifting ring B (4), and lifting ring A (3) and lifting ring B (4) are respectively connected with clamp A (5) and Fixture B (6) is welded, and the upper parts of fixture A (5) and fixture B (6) have notch A (9) and notch B (10) corresponding to lifting ring A (3) and lifting ring B (4). ), fixture A (5) and fixture B (6) are double-sided close-fitting interlaced bite, fixture A (5) and fixture B (6) are "U"-shaped steel plates, and in the middle of the "U"-shaped steel plate The connecting plate (7) is welded, and the lower ends of fixture A (5) and fixture B (6) are relatively bent with a 60º clip angle (11), and the lifting ...

Embodiment 3

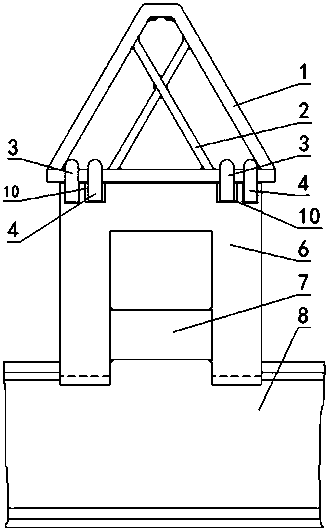

[0011] Embodiment 3: A galvanized frame hoisting jig, the hoisting frame (1) is an equilateral trapezoidal frame, and reinforcing ribs (2) are intersected and welded in the middle, so that it does not twist and deform when hoisting, and the hoisting frame (1) The lower part is hinged with clamp A (5) and clamp B (6) respectively through lifting ring A (3) and lifting ring B (4), and lifting ring A (3) and lifting ring B (4) are respectively connected with clamp A (5) and Fixture B (6) is welded, and the upper parts of fixture A (5) and fixture B (6) have notch A (9) and notch B (10) corresponding to lifting ring A (3) and lifting ring B (4). ), fixture A (5) and fixture B (6) are double-sided close-fitting interlaced bite, fixture A (5) and fixture B (6) are "U"-shaped steel plates, and in the middle of the "U"-shaped steel plate The connecting plate (7) is welded, and the lower ends of fixture A (5) and fixture B (6) are relatively bent with a 90° clip angle (11), and the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com