Wood product belt type grinding machine

A technology for grinding machines and wood products, which is applied in the direction of abrasive belt grinding machines, grinding machines, manufacturing tools, etc. It can solve the problems that affect the grinding effect, the belt body comes out, and the tension cannot be adjusted, so as to ensure normal operation and ensure the grinding effect , the effect of preventing prolapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

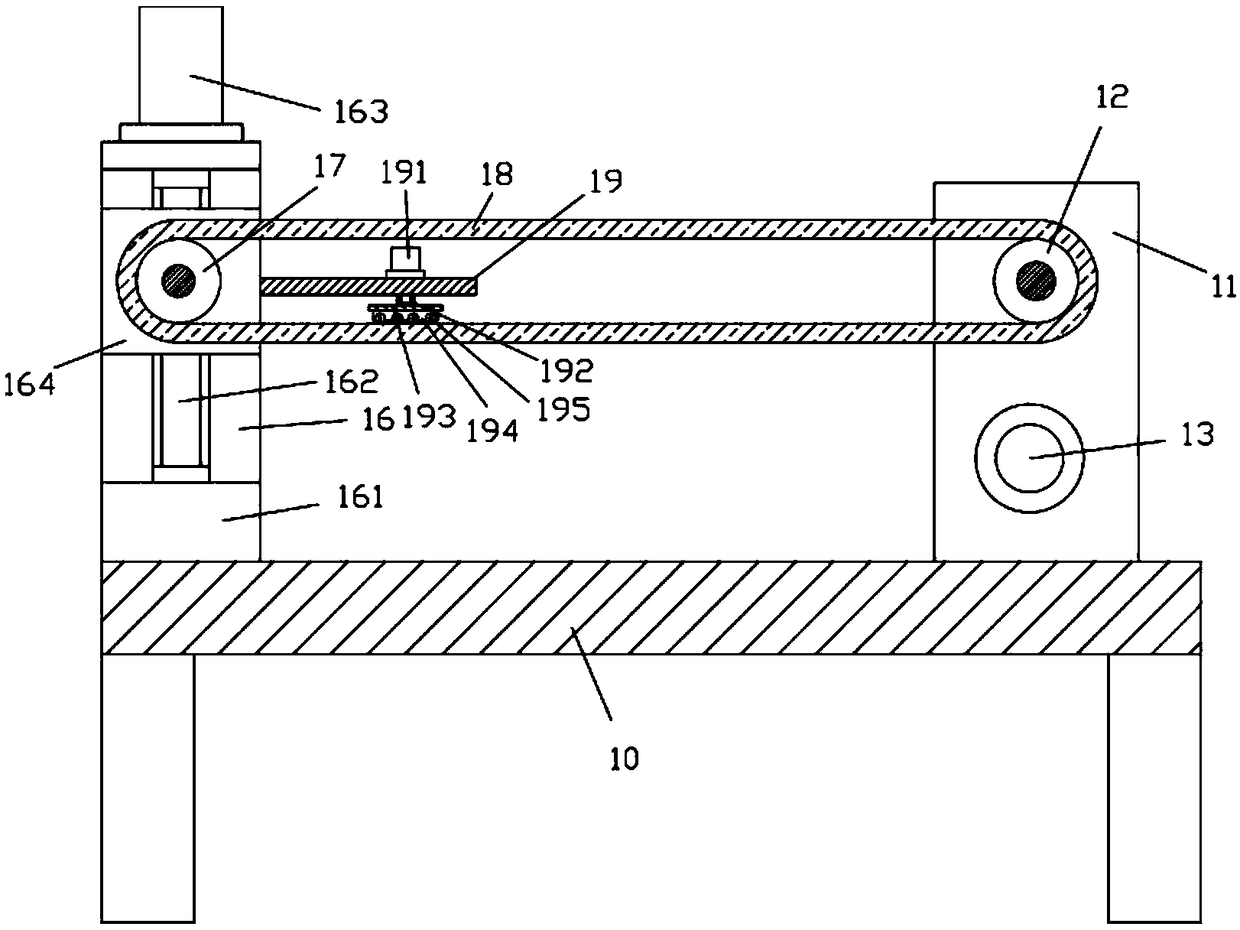

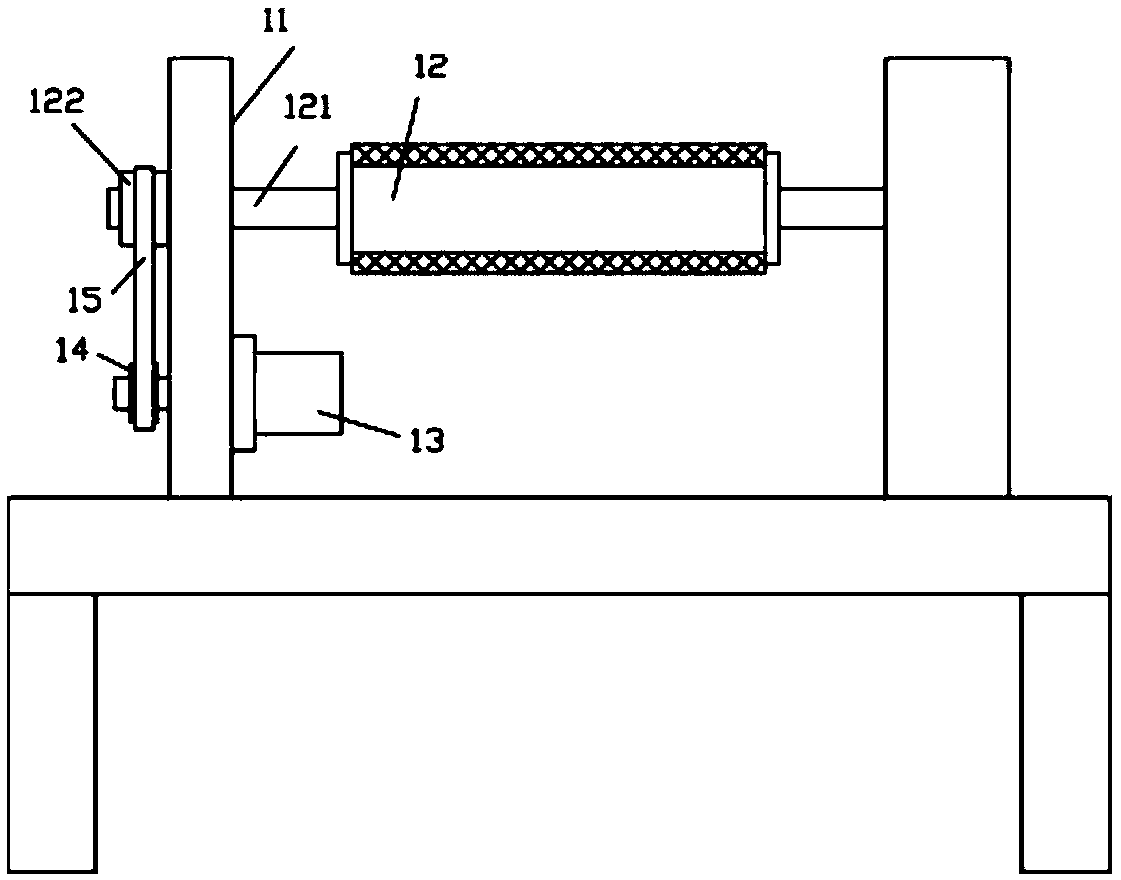

[0016] Example, see as Figure 1 to Figure 4 As shown, a wood product belt sander includes a frame 10, the front and rear of the right top surface of the top plate of the frame 10 are both fixed with a main support plate 11, and both ends of the main drive roller 12 The hinge shaft 121 is hinged on two main support plates 11, one of the hinge shafts 121 extends out of the corresponding main support plate 11 and is fixed with a transmission wheel 122, and a drive motor is fixed on the lower inner side wall of the main support plate 11 13. The output shaft of the drive motor 13 passes through the main support plate 11 and is fixed with a drive wheel 14, and the drive belt 15 is tensioned on the drive wheel 14 and the drive wheel 122;

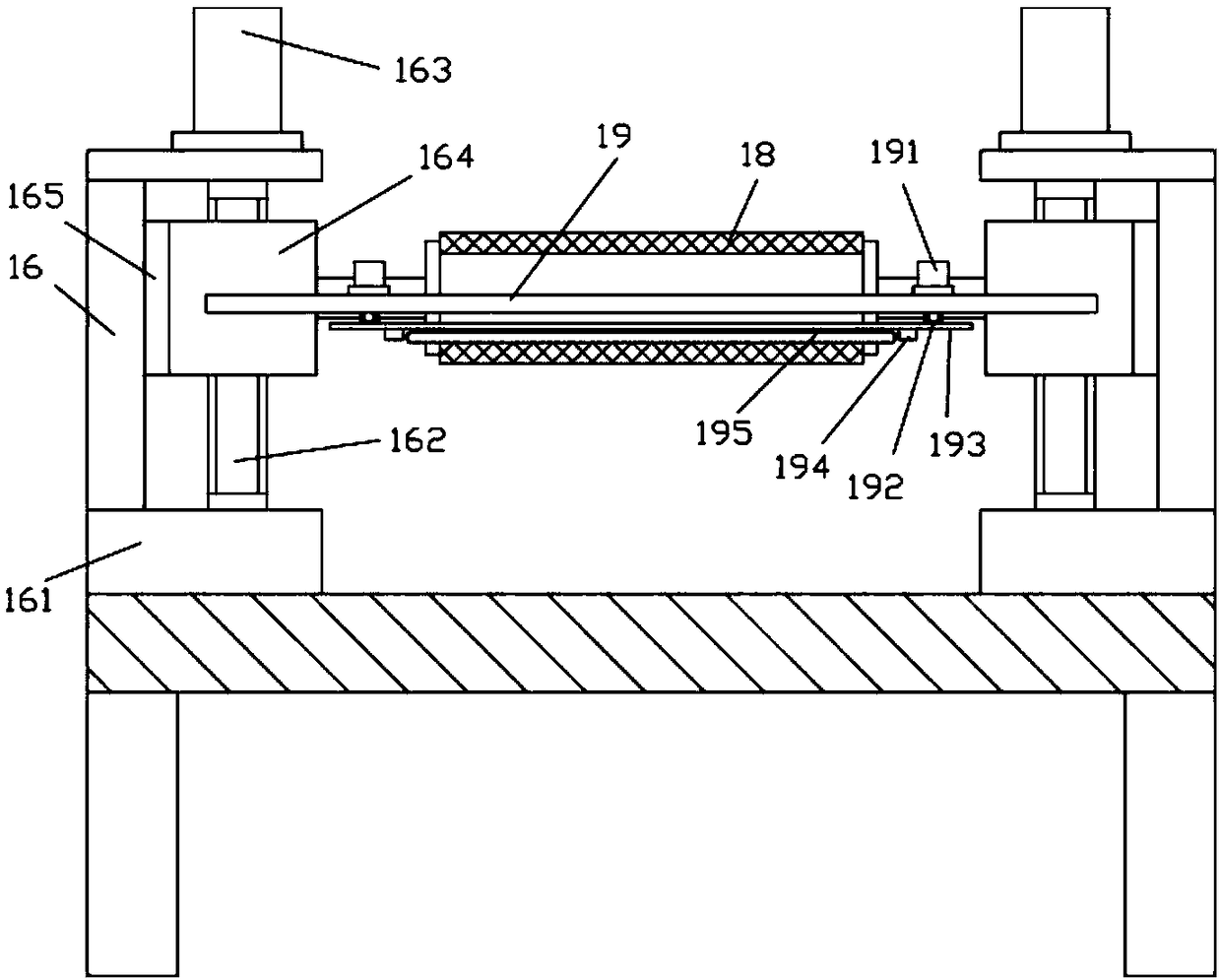

[0017] Both the front and the rear of the left top surface of the top plate of the frame 10 are fixed with an adjusting support plate 16. The upper and lower parts of the opposite wall surfaces of the two adjusting support plates 16 are fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com