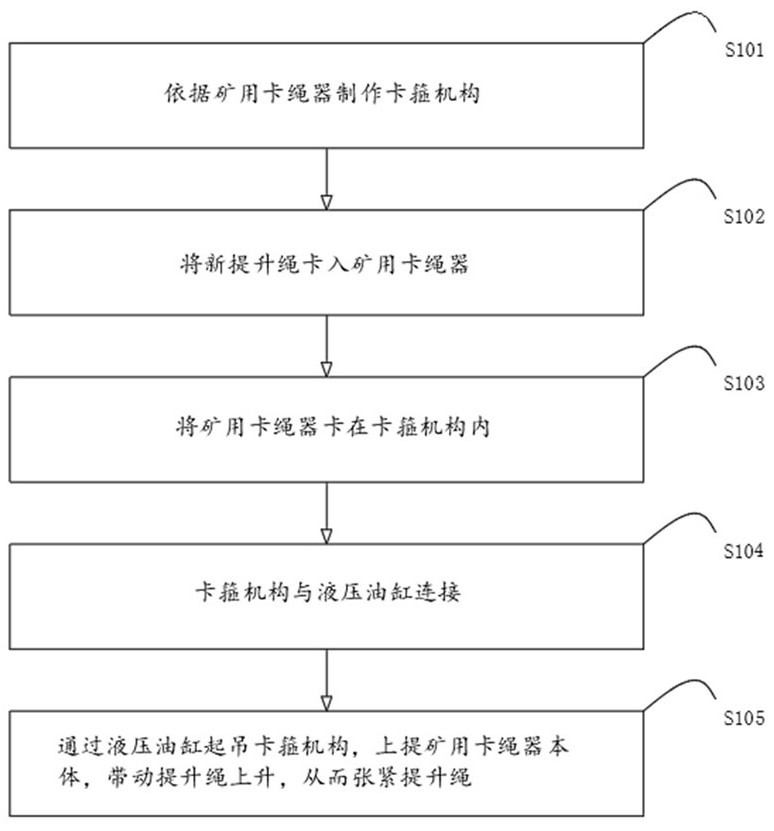

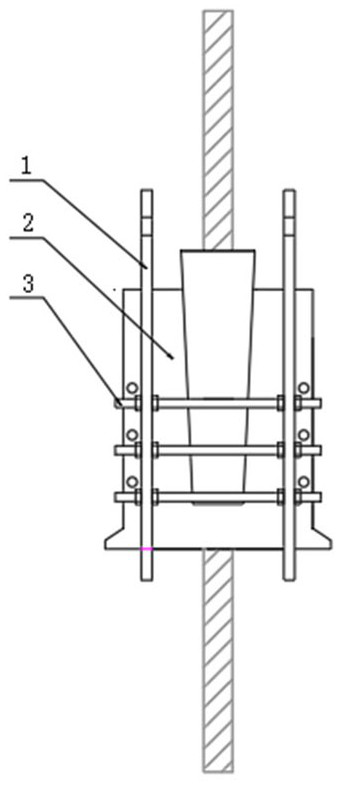

Construction method and system for tensioning vertical shaft hoisting rope

A construction method and hoisting rope technology, which is applied to lifting equipment, elevators, transportation and packaging in mines, can solve the problems of low tensioning efficiency of shaft hoisting ropes, and achieve safe and efficient completion, easy production and processing, and use The effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the operation of replacing the vertical shaft hoisting rope, the new wire rope will be slack or accumulated after being lowered for a certain distance, so it needs to be tensioned, and then a pair of steel plate clips are installed to fasten the new hoisting rope and the old rope clip stay. There are many ways to tension the wire rope, such as installing a pair of rope clips on the new hoisting rope and lifting it up with a hand hoist, or using a rope tensioner to keep the new hoisting rope in a clamped state during the lowering process. The former cycle removes and installs the board and loosens the chain hoist, which takes a long time to operate; the latter cannot effectively tighten the hoisting rope, and after the rope tightener is used for a period of time, the new hoisting rope will be too loose, or the new hoisting rope will be too loose. After the rope is accumulated, the problem that the residual rope cannot be effectively retracted. As a result, the existi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com