Sapphire dome grinding method

A grinding and sapphire technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of broken, sapphire chipping, fracture, etc., and achieve the effect of high surface quality and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

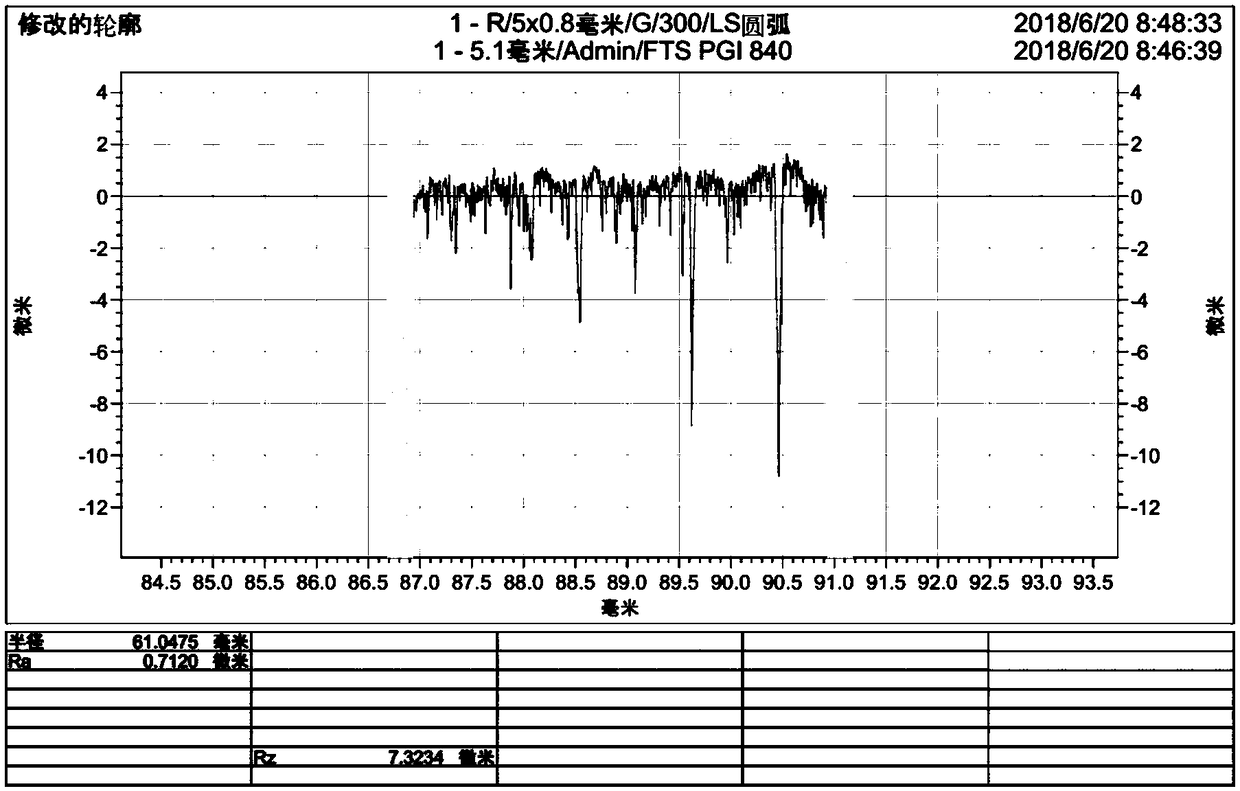

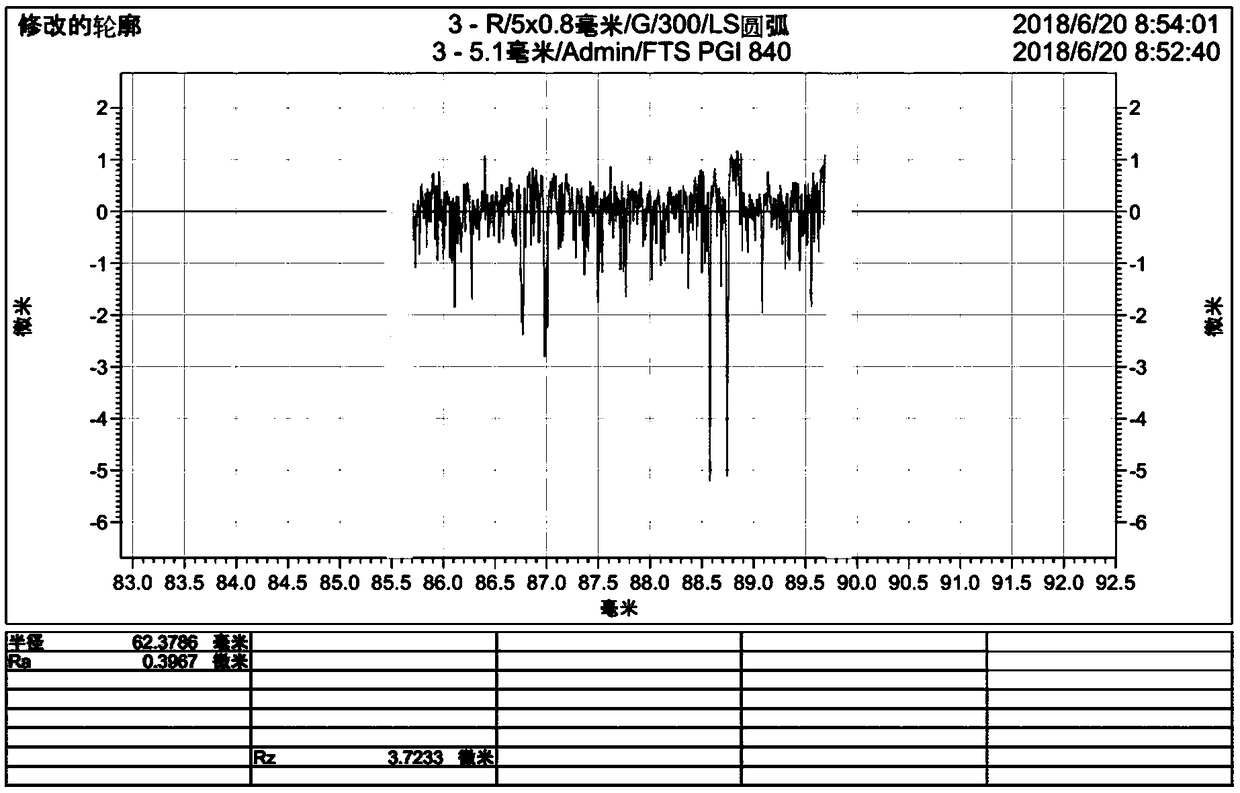

[0023] The Φ140×65mm single crystal sapphire is clamped on the CNC machine tool with a three-jaw chuck. First, the end face of the workpiece is ground with a cylindrical diamond grinding head to remove the uneven surface. Then grind the outer circle of the workpiece, and the grinding thickness is 0.3mm. Replace the diamond spherical grinding head to grind the inner spherical surface of the sapphire. The spherical grinding head with a particle size of #100 and #200 is used successively to perform rough grinding and semi-finish grinding on the inner spherical surface of the workpiece. The diameter of the grinding head is 28mm, the bonding agent is bronze, and it is made by electroplating. The grinding speed is 2000rpm, and the workpiece rotation speed is 60-70rpm. The feed rate during coarse grinding is 4mm / min, and the cutting amount is 0.5mm. During semi-fine grinding, the feed rate is 2mm / min, and the cutting amount is 10μm. Circular feeding, continuous expansion of the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com