A magnetron hot wire swing laser welding device, method and application

A technology of oscillating laser welding and hot wire, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor applicability, clumsy equipment, and difficulty in achieving the desired effect in molten pool control, and achieve strong practicability , reduce the unfused side wall, alleviate the effect of welding crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

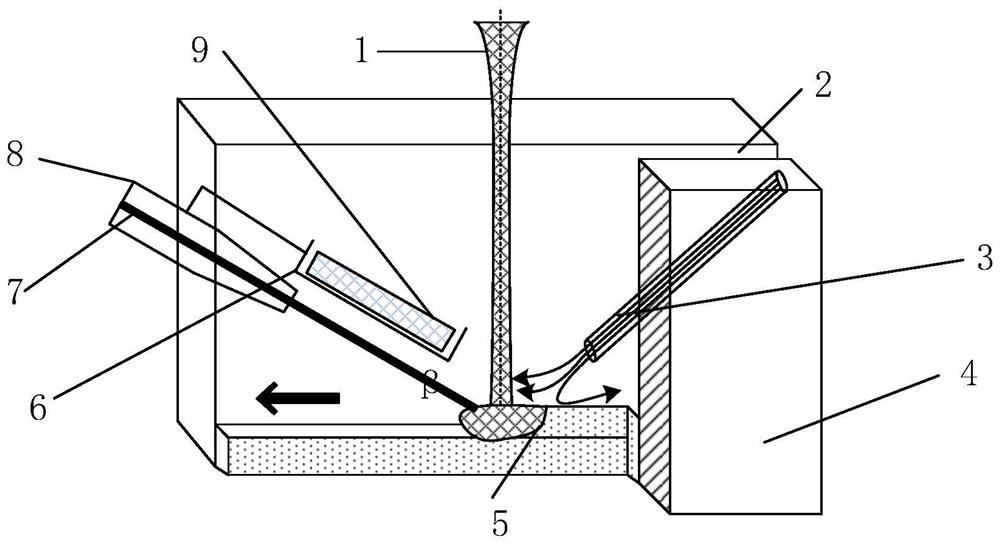

Method used

Image

Examples

Embodiment 1

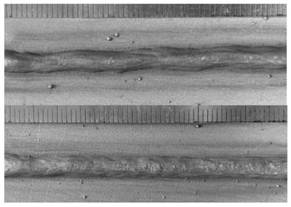

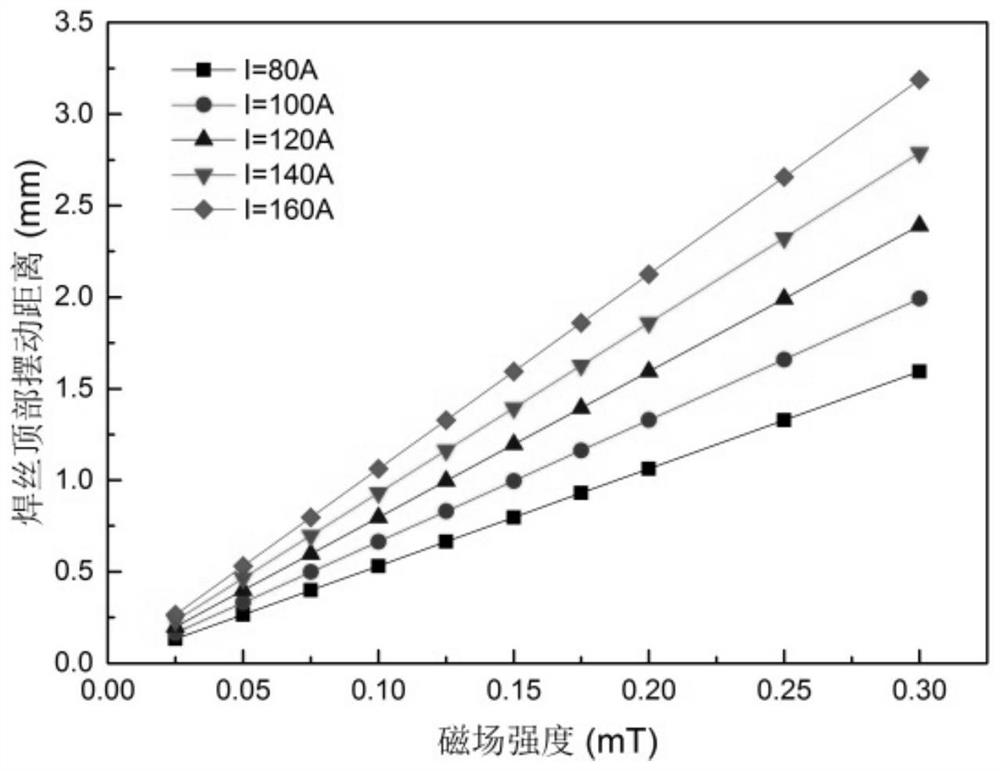

[0052] 1. Use plate surfacing to verify the influence of magnetron heating wire on joint forming. Using welding wire with a diameter of 1.2mm, the dry elongation of the welding wire is controlled at 20-40mm, the heating current of the hot wire is 80-100A, the wire feeding angle is 45°, the wire feeding speed is 2.5m / min, and the size of the permanent magnet device is 60mm *20mm*5mm, the magnetic field strength generated at the hot wire position is about 80-140mT, and the resulting welding wire deflection distance is about 1.0mm.

[0053] 2. The welding wire adopts the front wire feeding method, the shielding gas adopts pure Ar, the gas flow rate is 15L / min, and the rear gas supply is used to send the shielding gas pipe to the groove gap to protect the welding pool metal.

[0054] 3. The fiber laser is adopted, the laser power is 4000W, the welding speed is 1.5m / min, the laser is a continuous laser output, and the high-speed camera is used to observe the droplet transition beha...

Embodiment 2

[0056] 1. The stainless steel plate with a thickness of 50mm is notched, the blunt edge thickness B=3-4mm; the root gap P=2mm; the bottom groove spacing S=0.5-1.5mm; the groove angle β=2-4°. The stainless steel adopts the butt joint form, and the base metal to be welded is fixed by a clamp.

[0057] 2. Use welding wire with a diameter of 1.2mm, the dry elongation of the welding wire is controlled at 15-30mm, the heating current of the hot wire is 120-160A, the wire feeding angle is 45°, the wire feeding speed is 2.5m / min, and the size of the permanent magnet device is added. It is 60mm*20mm*5mm, the magnetic field intensity generated at the hot wire position is about 60-120mT, and the resulting welding wire deflection distance is about 0.5mm.

[0058] 3. The welding wire adopts the front wire feeding method, the shielding gas adopts pure Ar, the gas flow rate is 15L / min, and the rear gas supply is used to send the shielding gas pipe to the groove gap to protect the welding poo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com