Shoe setting machine

A technology for shaping machines and shoes, which is applied to shoemaking machinery, shoe uppers, footwear, etc., and can solve problems such as low shaping efficiency, single function, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

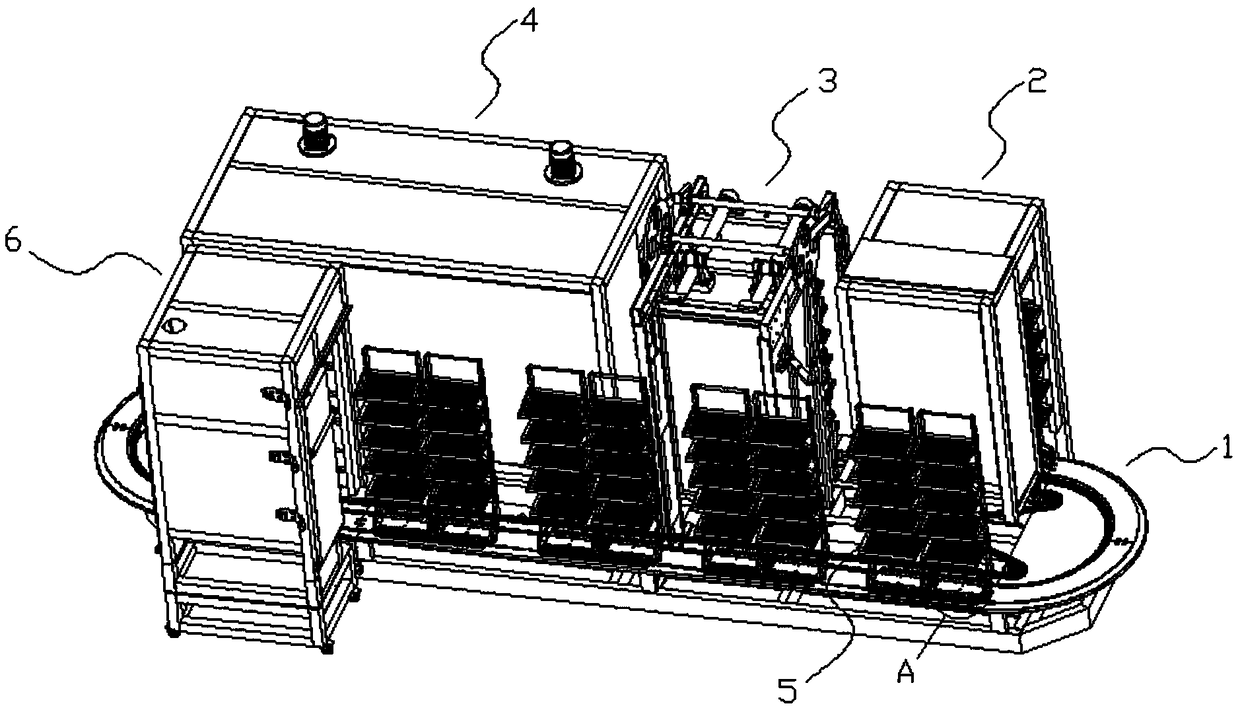

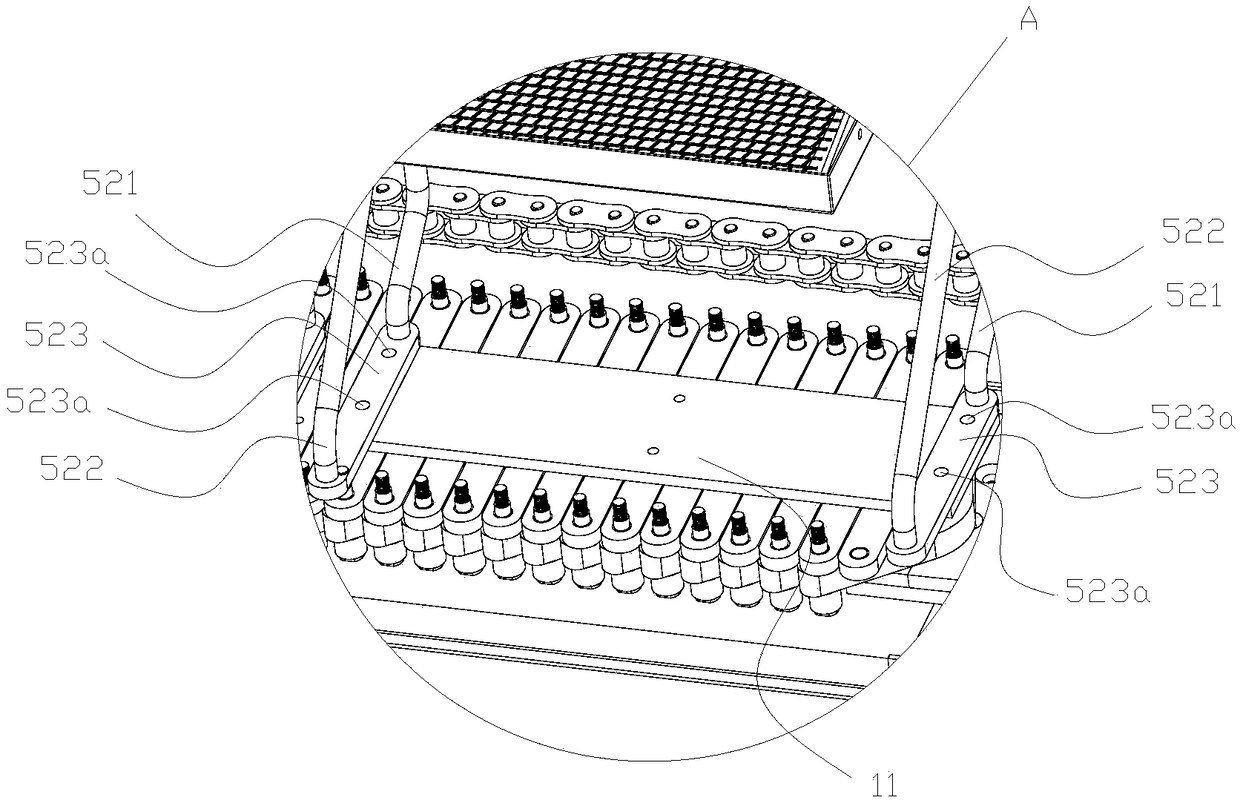

[0033] Please refer to Figure 1 to Figure 2 , a kind of shoe shaping machine, comprises conveying track 1, preheating box 2, shaping box 3 and drying box 4, and preheating box 2, shaping box 3 and drying box 4 are arranged on the top of conveying track 1 successively along conveying track, also Including a shoe rack 5 and a cooling box 6, the shoe rack 5 is installed on the conveying track 1, and the cooling box 6 is arranged on the conveying track 1;

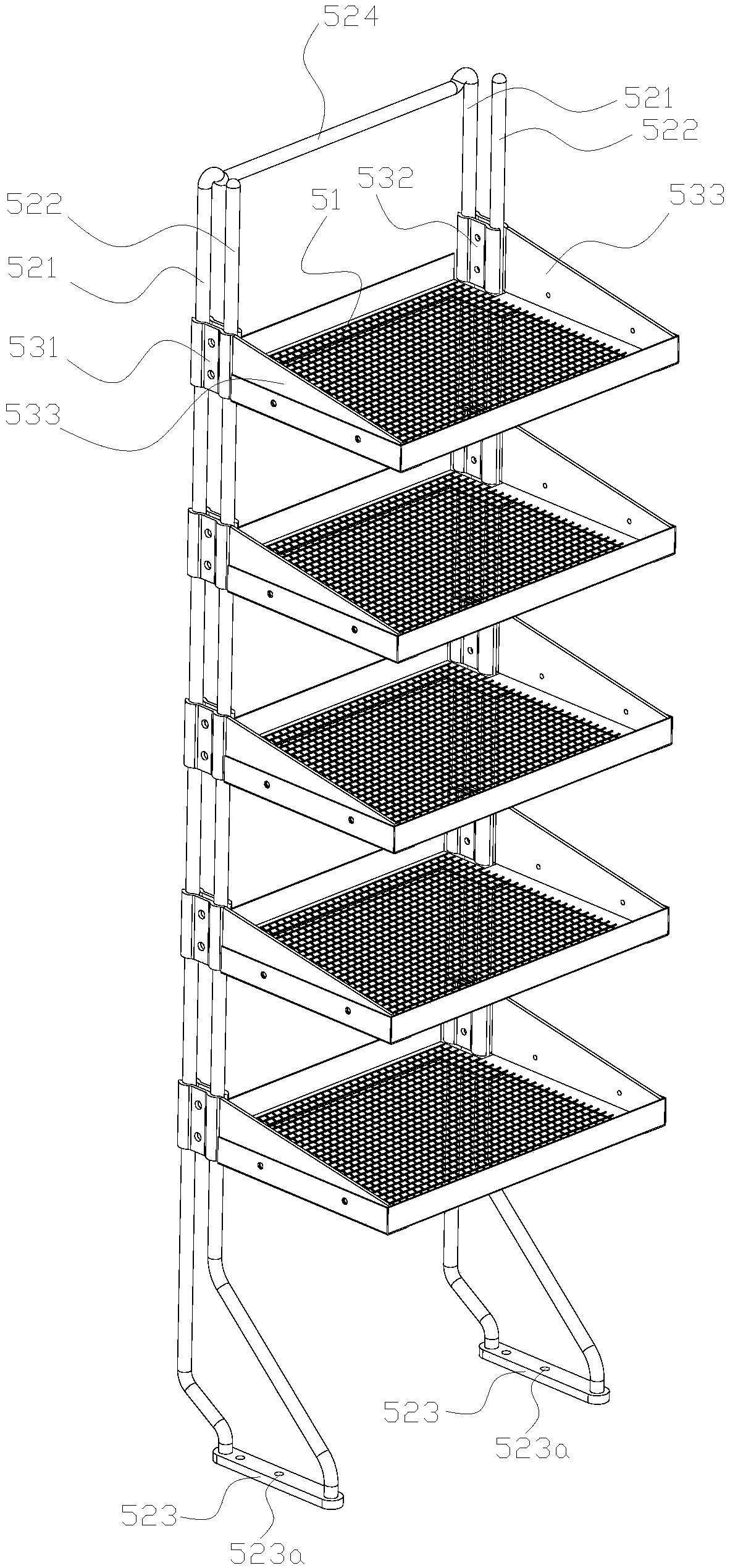

[0034] Please refer to Figure 3 to Figure 6 The shoe rack 5 includes a plurality of shoe trays 51 , a fixing frame 52 and a plurality of supporting frames 53 , the plurality of shoe trays 51 are fixedly connected to the supporting frame 53 , and the plurality of supporting frames 53 are detachably connected to the fixing frame 52 .

[0035] Further, the fixing frame 52 includes a pipe body 1 521, a pipe body 2 522 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com