Lithium ion battery, diaphragm and preparation method thereof

A separator and polypropylene film technology, applied in the field of lithium-ion batteries, can solve the problems of inability to fix the size of the base film, weak interfacial bonding force, and close packing of ceramic particles, so as to improve the liquid absorption and liquid retention performance and prevent retraction deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the lithium ion battery of an embodiment, comprises the steps:

[0048] 1. Diaphragm preparation;

[0049] (1) Preparation of polyacrylate modified hollow ceramic nanotubes

[0050] (a) Ultrasonically disperse the hollow ceramic nanotubes in a solvent, add a silane coupling agent after heating, adjust the pH with ammonia water, and react for a period of time under mechanical stirring. The product is separated and dried to obtain halloysite nanotubes modified by silane coupling agent.

[0051] (b) Add the prepared coupling agent-modified hollow ceramic nanotubes, deionized water, emulsifier, and acrylate monomer into the reactor for high-speed stirring and dispersion, heat up and slowly add the diluted potassium persulfate aqueous solution dropwise. React in the atmosphere. After the reaction is finished, the product is washed and dried to obtain polyacrylate modified hollow ceramic nanotubes.

[0052] (2) Preparation of modified hollow cera...

Embodiment 1

[0081] Diaphragm preparation:

[0082] (1) Preparation of polyacrylate modified hollow ceramic nanotubes

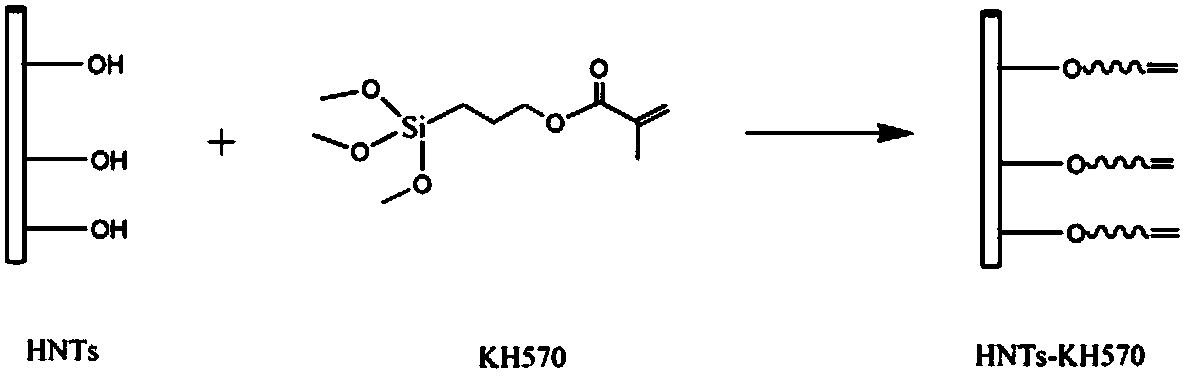

[0083] (a) Take 40.00g of halloysite nanotubes and add them to 500ml of 95% ethanol for ultrasonic dispersion for 2h, then transfer them to a three-necked flask, and add 2.00g of γ-(methacryloyloxy)propyltrimethoxysilane at one time, The temperature was raised to 50° C., the pH was further adjusted to 7.0 with ammonia solution, and the reaction was carried out for 4 hours under mechanical stirring. After the reaction is finished, the halloysite nanotubes modified by the coupling agent are obtained by centrifuging, washing and drying. The reaction formula is as follows:

[0084]

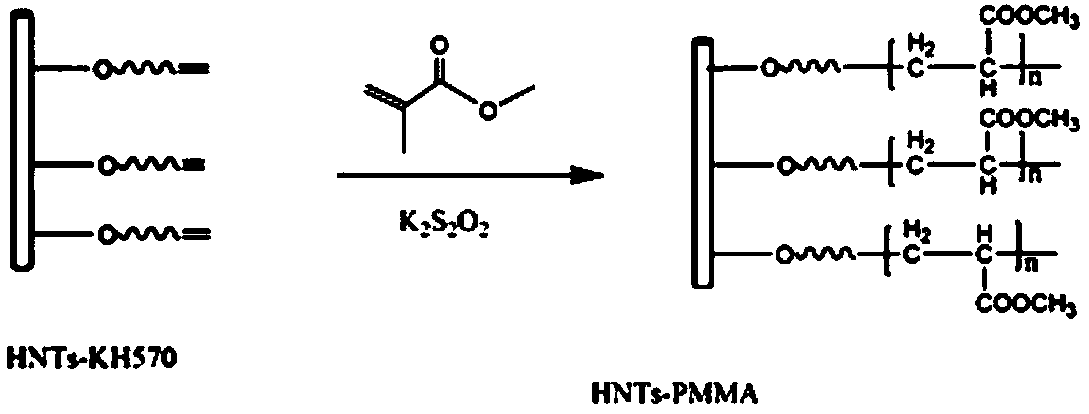

[0085] (b) Take 30.00g coupling agent modified halloysite nanotubes, 0.08g sodium dodecylbenzenesulfonate, 300ml deionized water, 4.00g methyl methacrylate monomer, and stir at a high speed at 1500r / min . The temperature was raised to 60° C., and 1.50 g of 2% potassium persulfate dilute so...

Embodiment 2

[0090] Diaphragm preparation:

[0091] (1) Preparation of polyacrylate modified hollow ceramic nanotubes

[0092] (a) Take 40.00g of halloysite nanotubes and add them to 500ml of 95% ethanol for ultrasonic dispersion for 2h, then transfer them to a three-necked flask, and add 4.00g of γ-(methacryloyloxy)propyltrimethoxysilane at one time, The temperature was raised to 60° C., the pH was further adjusted to 8.0 with ammonia solution, and the reaction was carried out under mechanical stirring for 6 hours. After the reaction is finished, the halloysite nanotubes modified by the coupling agent are obtained by centrifuging, washing and drying. The reaction formula is as follows:

[0093]

[0094] (b) Take 30.00 g of halloysite nanotubes modified by coupling agent, 0.08 g of fatty alcohol polyoxyethylene ether, 300 ml of deionized water, and 3.00 g of ethyl acrylate monomer, and stir at 2000 r / min at high speed. The temperature was raised to 70° C., and 1.50 g of 2% potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com