Testing method of 1000kV extra high tension series-compensated protection exit loop

A technology for series compensation protection and loop testing, which is applied in the direction of electronic protection circuit testing, electronic circuit testing, coating, etc. It can solve the problems of unspecified connection quantity, time-consuming work, and only description, so as to facilitate searching and prompting, Avoid forgetting and loss, good fluorescent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

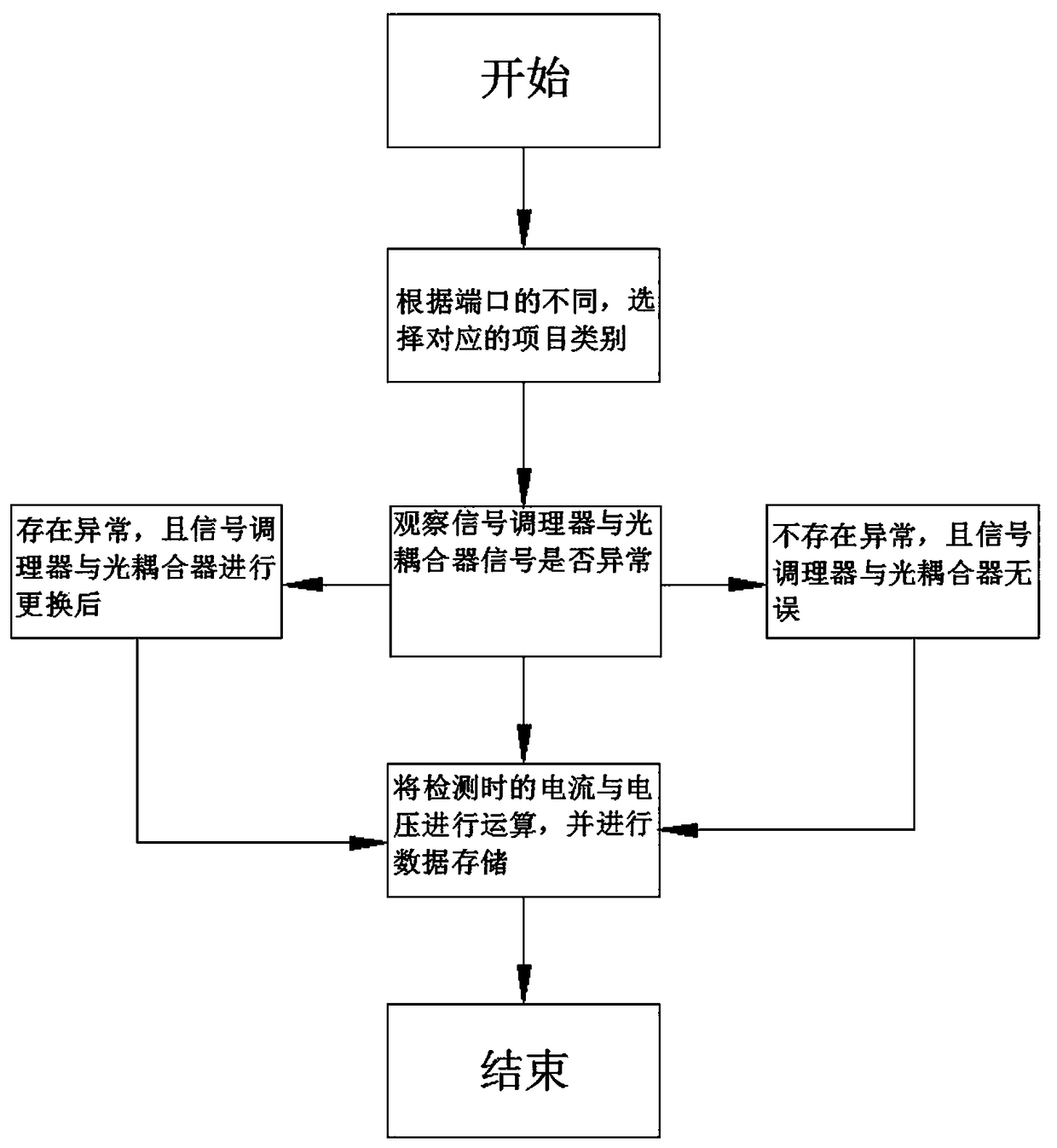

[0033] A method for testing the outlet circuit of 1000 kV UHV series compensation protection, the steps are as follows:

[0034] S1: Turn on the power to make the data processing module work, and select the corresponding item category according to the different detection positions, and perform calculations through the data processing module;

[0035] S2: Then the signal conditioner is connected through the data processing module, and the connection status of the port can be obtained from the indicator light, and the timing can be started from the time of connection, and the voltage value and current value of the port can be obtained, and sent to the data processing module Compare it with the original data in the storage unit to obtain data information within a fixed period of time;

[0036] S3: If the test data is not within the limited range of data, an alarm will be issued through the alarm, and the data will be generated by the data processing module to generate an alarm en...

Embodiment 2

[0047] The difference between it and Embodiment 1 is that further, the item category includes skipping serial compensation phase A, jumping serial compensation phase B, jumping series compensation phase C, jumping series compensation three phases, failure jumping T031, failure Jump T032, fail to send remote transmission, separate T631A phase, close T631A phase, separate T631B phase, close T631B phase, separate T631C phase, close T631C phase, dual-system power-down protection exit 1, dual-system power-failure protection exit 2, temporarily lock T631 for measurement and control, T631 for permanent blocking measurement and control, and T631 for blocking measurement and control.

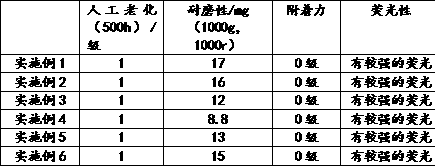

[0048] Wherein the fluorescent paint is mainly made of the following raw materials in parts by weight:

[0049] 32 parts of acrylic emulsion, 28 parts of alkyd resin, 4 parts of fluorescent powder, 2.5 parts of glass microspheres, 1.8 parts of glass fiber, 9 parts of titanium dioxide, 8 parts of ultrafin...

Embodiment 3

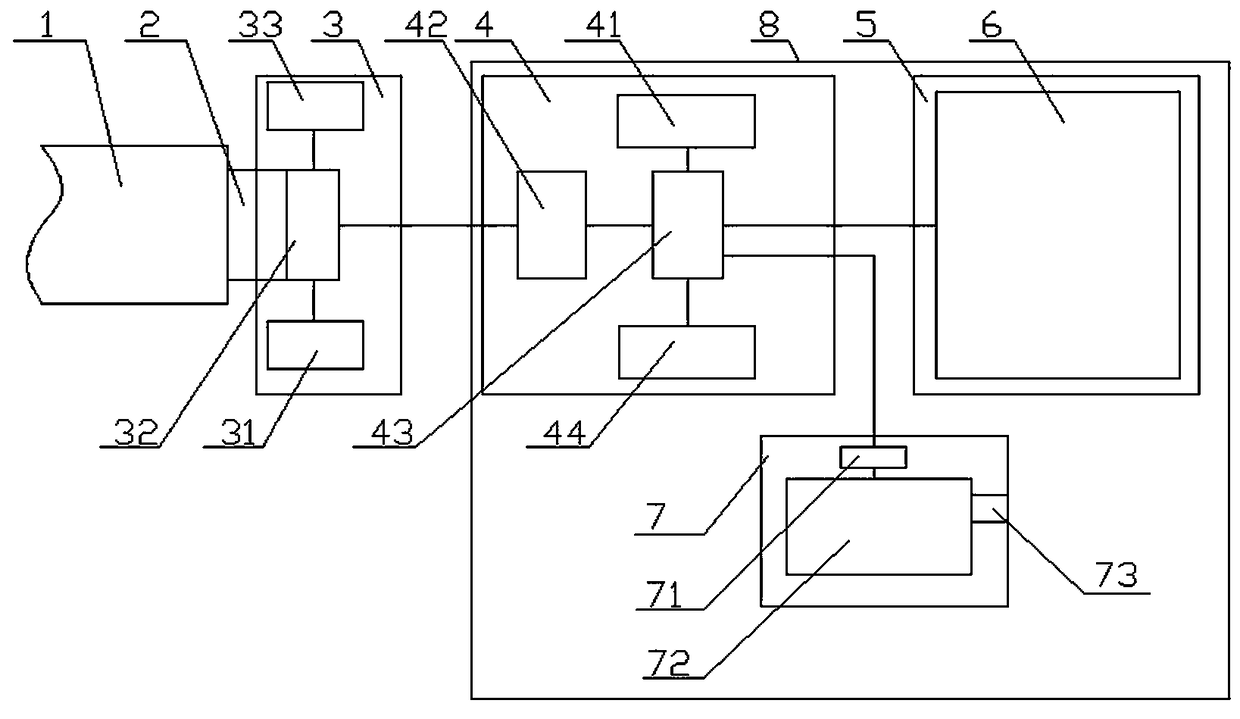

[0053] The difference from Embodiment 2 is that the data display module includes a display screen 6 interconnected with the data processing module 43, a protective frame 5 arranged around the display screen 6, and a protective frame 5 arranged on the protective frame. 5 on the protective screen.

[0054] The power supply unit 7 includes a rechargeable battery 72 electrically connected to the data processing module 43, a charging and discharging port 73 connected to the rechargeable battery 72, and a charging port 73 arranged on the rechargeable battery 72 and connected to the data processing module 43. connected to the switch 71.

[0055] Wherein the fluorescent paint is mainly made of the following raw materials in parts by weight:

[0056] 34 parts of acrylic emulsion, 26 parts of alkyd resin, 5 parts of fluorescent powder, 3 parts of glass beads, 1.6 parts of glass fiber, 10 parts of titanium dioxide, 7 parts of ultrafine barium sulfate, 9 parts of ethanol, 8 parts of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com