System and method used for simultaneous on-line monitoring of plurality of heavy metals in water

A monitoring system, heavy metal technology, applied in measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc., can solve the problem of inability to simultaneously measure two or more heavy metal ions, low sensitivity of heavy metal online analysis, and instrument volume and cost increase, to achieve the effects of short measurement time, low operation and maintenance requirements, and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

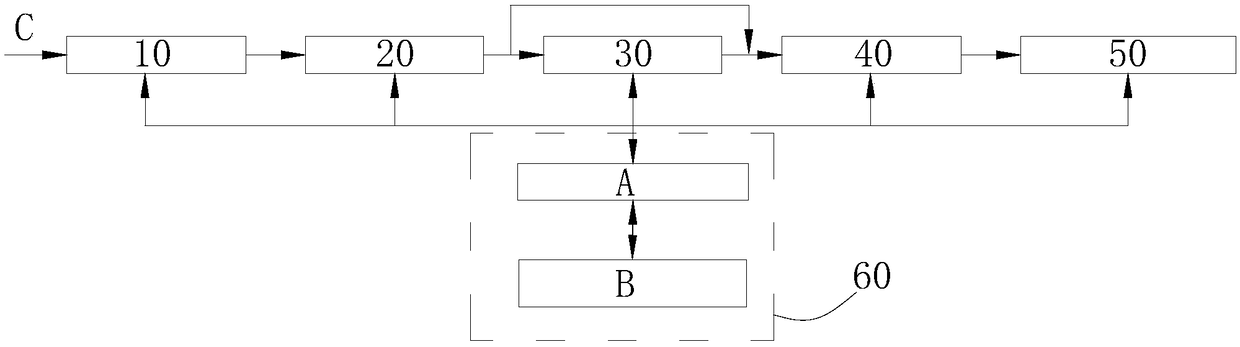

[0041] The letters in the figure of this embodiment are respectively represented as: A, signal acquisition and control; B, operation control and information processing; C, sample.

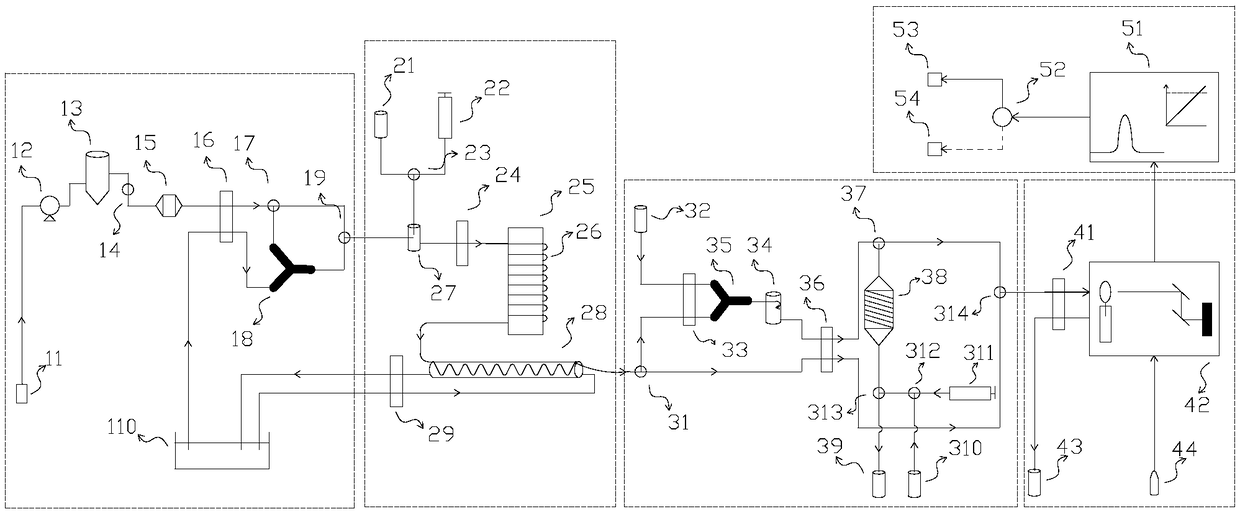

[0042] refer to figure 1 , figure 2 and Figure 6 , is a simultaneous online monitoring system for multiple heavy metals in water, including an online sampling module 10 for regularly collecting samples and performing pretreatment, an online digestion module 20 for continuous online thermal digestion, and an online enrichment module for enrichment Module 30, online detection module 40, data processing / output module 50 for comparing and analyzing the detection results with corresponding water quality standard standard limits, system control module 60 for controlling the operation of each module; online sampling module 10, online The digestion module 20, the online enrichment module 30, and the online detection module 40 are connected in sequence; the sample solution digested by the online digesti...

Embodiment 2

[0064] refer to image 3 , the present embodiment provides a method for online monitoring of multiple heavy metals in water at the same time, and its specific process is as follows:

[0065] a) On-line sampling: On-line use the module to control the water pump 12 to suck the water sample into the water pipe filter and lift it into the settling cup 13, and separate the coarse impurities such as gravel and waste residue in the water sample under the action of gravity, after reaching the preset settling time , the control module starts the two-way electromagnetic valve 14 and the water sample after the sedimentation is passed through the fiber (or nylon) screen 15 to filter the suspended solids of fine particle size, and then the filtered water sample is passed through three stages by the first DC motor peristaltic pump 16. Through the reversing ball valve 17 and the first three-way solenoid valve 19 and lift to the online digestion module 20.

[0066] Further, the settling time...

Embodiment 3

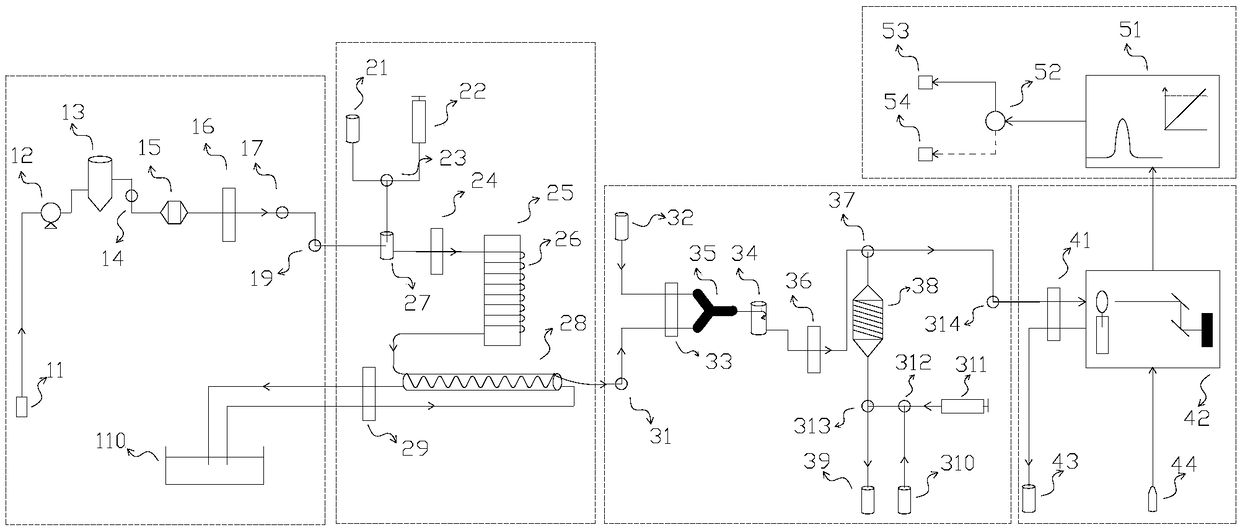

[0084] see Figure 4 , this embodiment provides a simultaneous online monitoring system and method for multiple heavy metals in water. The difference from Embodiment 2 is that the solution after digestion and cooling directly enters the emission spectrum detection device 42 for detection, which is applicable to various types of surface water and ground water. , On-line monitoring of heavy metals in industrial wastewater. The specific process of the method is as follows:

[0085] a) According to steps 1 and 2 described in Example 1, online sampling and digestion of water samples are carried out.

[0086] b) By switching the circuit, the control module controls the fourth DC motor peristaltic pump 36 to lift the solution flowing out of the condensation pipe 28 through the third three-way solenoid valve 31 and the seventh three-way solenoid valve 314 to the online detection module 40 .

[0087] c) Analyzing, detecting and data processing the solution according to Step 4 describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com