Burner with burning knob and flame continuous control method based on burning knob

A control method and burner technology, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as continuous combustion control, avoid high-temperature pollutants, avoid high-temperature damage, and achieve the effect of flame regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

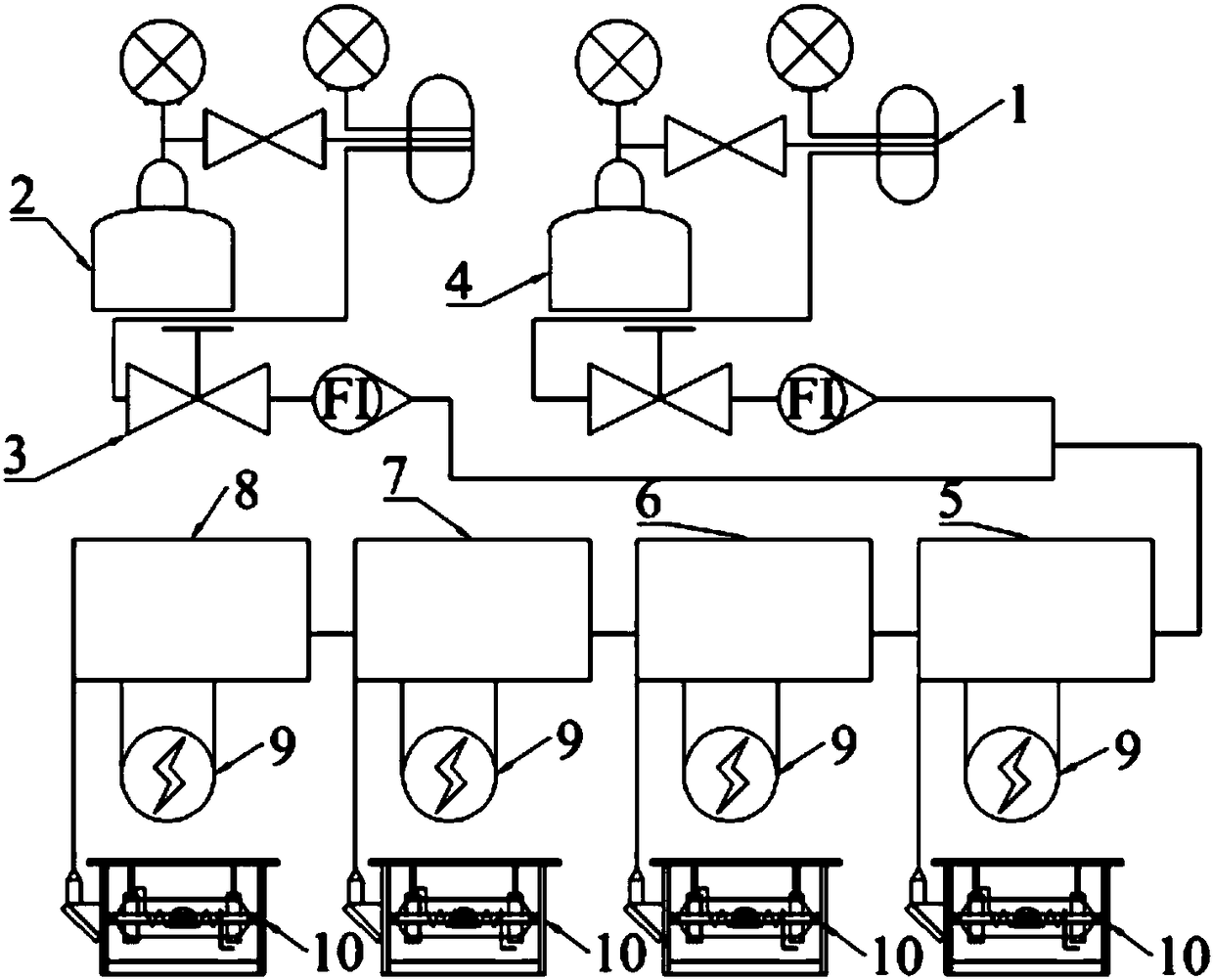

[0026] In order to illustrate the technical solution of the present invention more clearly, the accompanying drawings that need to be used in the description will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. As far as people are concerned, other embodiments can also be obtained according to these drawings on the premise of not paying creative work.

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

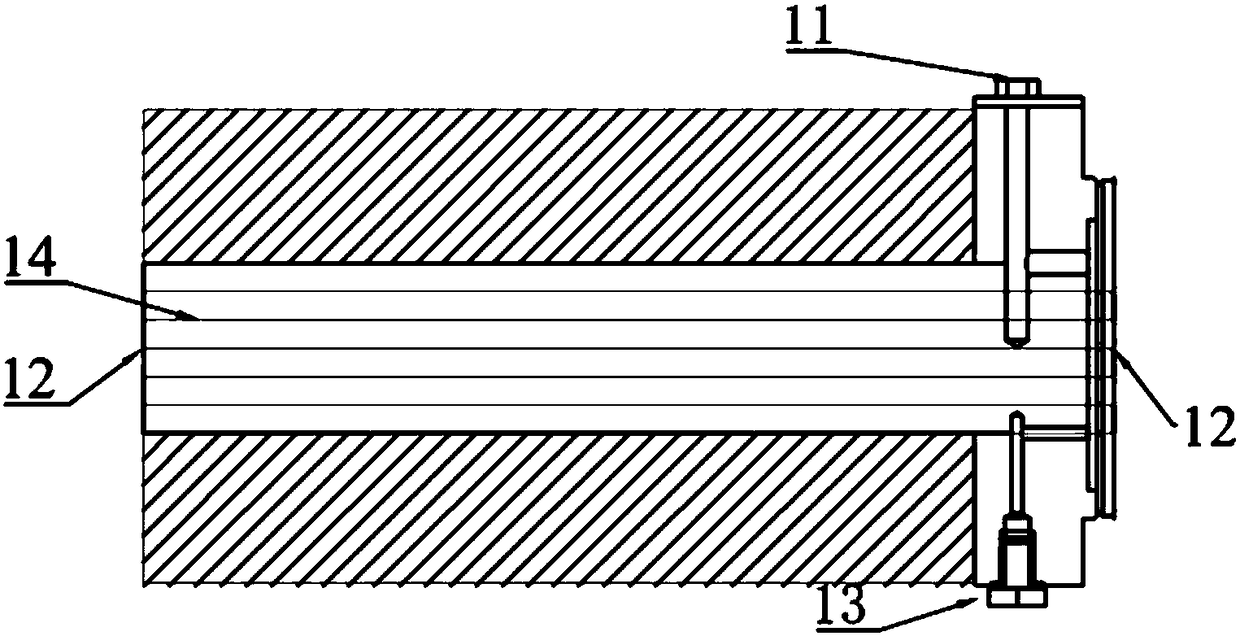

[0028] Such as figure 2 Shown:

[0029] The burner of the present invention has the burner passage 14 that is made of porous medium ceramic material; Extinguishing grid 12 (for example metal grid sheet) is installed in burner inlet and outlet; 11 is a silicon-molybdenum material electric heating rod, and a temperature detection device 13 is also arranged in the burner, and the temperature d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com