Manufacturing method of hydrogen oxygen generator of combustion machine

A production method and generator technology, which is applied in the production field of hydrogen-oxygen generators for burners, can solve the problems of large pollution discharge and shortage of natural gas sources, and achieve the effects of high calorific value, alleviating the shortage of gas sources, and saving gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

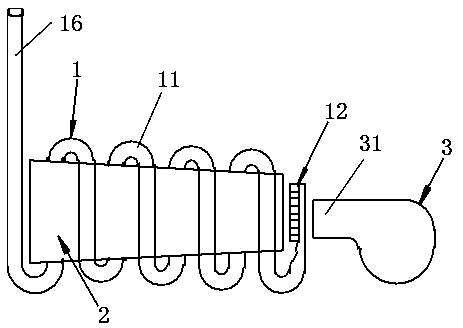

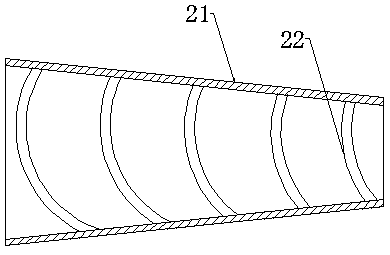

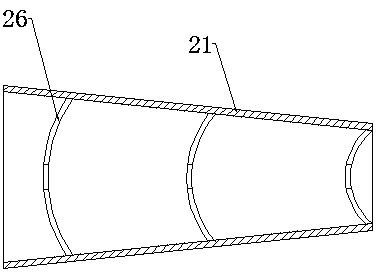

[0032] A method for making a hydrogen-oxygen generator for a burner, comprising the following steps: ① first melting 35kg of nickel, 15kg of scandium, and 50kg of lanthanum oxide, and then melting 30kg of titanium; ② melting the melted nickel, lanthanum oxide and The titanium mixture is evenly poured into the mold, and cast into a hydrogen-oxygen generator. The hydrogen-oxygen generator includes a cylinder, and blades are arranged inside the cylinder, and the blades are described. The outer side of the hydrogen-oxygen generator is wound with a steam generator, the steam generator includes a water pipe spirally wound on the hydrogen-oxygen generator, one end of the water pipe is a water inlet, and the other end is provided with an air injection port; the air injection port and the burner are connected The crater is adjacent. A circular plate is provided at the air injection port, and several air injection holes arranged in a circle are arranged at the edge of the circular plat...

Embodiment 2

[0034] A method for making a hydrogen-oxygen generator for a burner, comprising the following steps: ① first melting 10kg of nickel, 5kg of scandium, and 80kg of lanthanum oxide, and then melting 10kg of titanium; ② melting the melted nickel, lanthanum oxide and Titanium is evenly mixed and poured into a mold, and cast into a hydrogen-oxygen generator 1 . Other steps are the same as in Example 1.

Embodiment 3

[0036] A method for making a hydrogen-oxygen generator for a burner, comprising the following steps: ① melting 60kg of nickel, 30kg of scandium, and 20kg of lanthanum oxide, and then melting 50kg of titanium; ② melting the melted nickel, lanthanum oxide, and Titanium is evenly mixed and poured into a mold, and cast into a hydrogen-oxygen generator 1 . Other steps are the same as in Example 1.

[0037] Embodiment 1, embodiment 2 and embodiment 3 fused and cast oxyhydrogen generators, after using for 3 months, there is no phenomenon of corrosion, no oxidation, no damage and fracture. Different boilers, different combustion methods and different generators for power generation. According to the situation, the shape is changed, but the formula is not changed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com