Carbon fiber composite material with high compressive strength and high-pressure draw ratio and preparation method thereof

A Rabi carbon fiber and composite material technology, which is applied in the field of composite materials, can solve the problems of low compression, bending and compression-tension balance performance, difficulty in meeting the requirements of new equipment, and reduced weight reduction effect, so as to achieve high impregnation efficiency and increase Effects of interfacial bonding force, interlayer shear performance, and mechanical strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

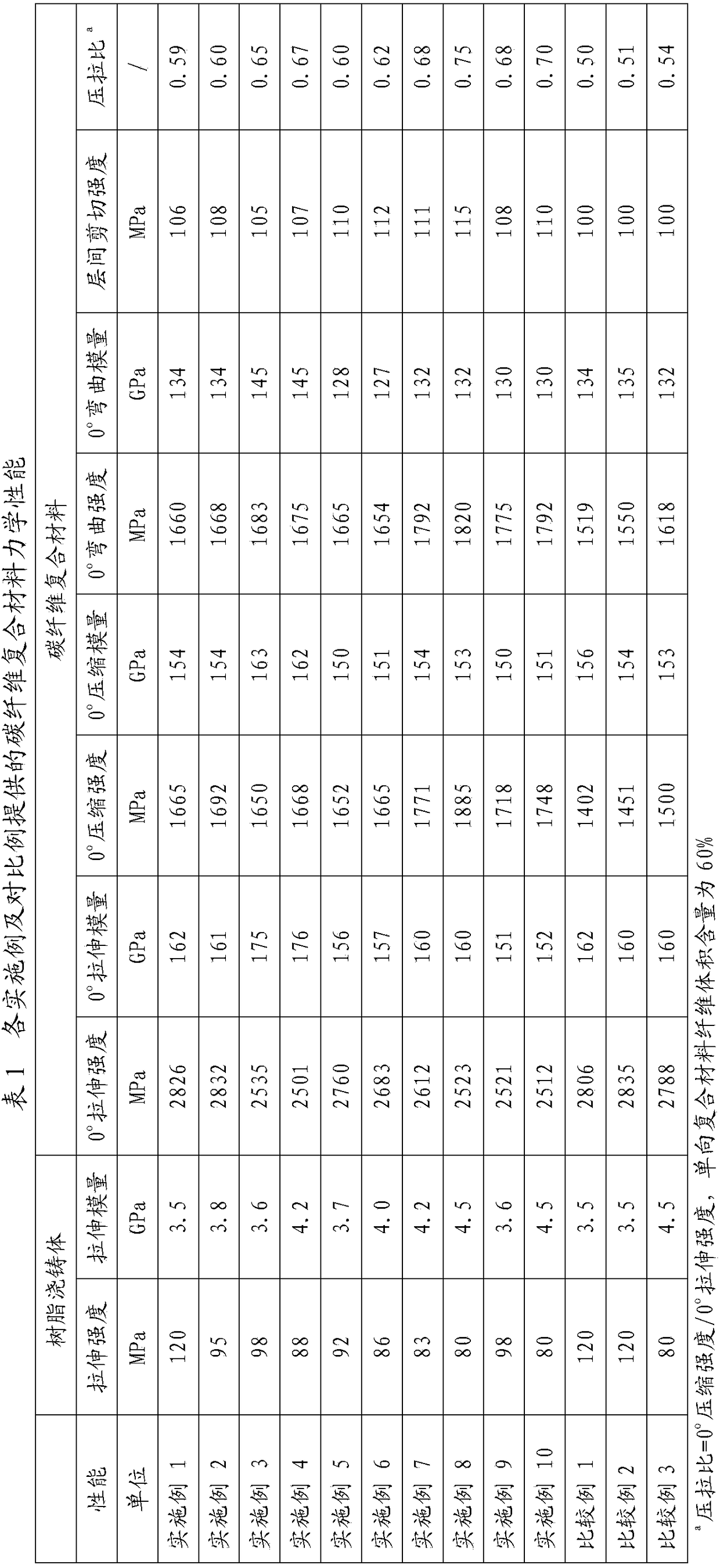

Examples

preparation example Construction

[0030] The embodiment of the present invention provides a method for preparing a carbon fiber composite material with high compressive strength and high-pressure ratio, comprising the following steps:

[0031] Step 1, 100 parts by mass of resin, 30-60 parts by mass of curing agent, 0.5-2 parts by mass of accelerator and 0.1-3 parts by mass of inorganic nanoparticles to obtain a resin matrix;

[0032] Specifically, in the embodiment of the present invention, high-speed mechanical stirring is used to uniformly disperse the inorganic nanoparticles in the matrix resin, and the defoaming treatment is ready for use; the inorganic nanoparticles are preferably functionalized particles with different functional groups from the surface treatment liquid in step 2, and can be mixed with carbon fiber The chemical reaction on the surface strengthens the bonding force between the resin and the fiber interface.

[0033] Step 2, impregnating carbon fibers with a fiber diameter of 5.4-7.0 μm in...

Embodiment 1

[0040] The TG800 high-strength medium-model carbon fiber (tensile strength: 6200MPa, tensile modulus: 295GPa) with a fiber monofilament diameter of 5.4 μm is pulled and soaked at a rate of 0.1m / min, and then dried and wound through the surface treatment solution. The surface treatment solution is composed of the following mass: Component composition: 20 parts of γ-aminopropyltriethoxysilane, 18 parts of ethanol, 62 parts of water, 0.1 part of hydroxylated graphene;

[0041] 68 parts of 4,4'-diaminodiphenylmethane tetraglycidyl epoxy resin, 32 parts of bisphenol A glycidyl ether epoxy resin, 60 parts of diaminodiphenylsulfone, 0.5 parts of benzyldimethylamine , 0.1 part of carboxylated graphene mixed at a high speed and uniformly prepared to obtain a matrix resin system; impregnating pre-surface-treated carbon fibers into the resin matrix to prepare a prepreg; laying and curing the prepreg to obtain a high Compressive strength and high-pressure ratio carbon fiber composite mate...

Embodiment 2

[0043] The TG800 high-strength medium-model carbon fiber (tensile strength: 6200MPa, tensile modulus: 295GPa) with a fiber monofilament diameter of 5.4 μm was pulled and soaked at a rate of 0.1m / min, and then dried and wound through the surface treatment solution. The composition of the surface treatment solution was 20 Parts of γ‐aminopropyltriethoxysilane, 18 parts of ethanol, 62 parts of water, 0.1 part of hydroxylated graphene;

[0044] 68 parts of 4,4'‐diaminodiphenylmethane tetraglycidyl epoxy resin, 32 parts of bisphenol A glycidyl ether epoxy resin, 60 parts of diaminodiphenylsulfone, 0.5 part of benzyldimethylamine , 0.5 parts of carboxylated carbon nanotubes are mixed at high speed and stirred evenly to prepare a matrix resin system; impregnating pre-treated carbon fibers into the resin matrix to prepare a prepreg; laying and curing the prepreg to obtain a high Compressive strength and high-pressure ratio carbon fiber composite materials, the curing process is (130°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com