Coating polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene technology, which are applied in the field of plastic packaging, can solve the problems of lowering the heat-sealing temperature of the coating film, and the strength of the coating film does not show advantages, etc., and achieve fast heat-sealing speed, stable processing and production, and heat-sealing. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through embodiment.

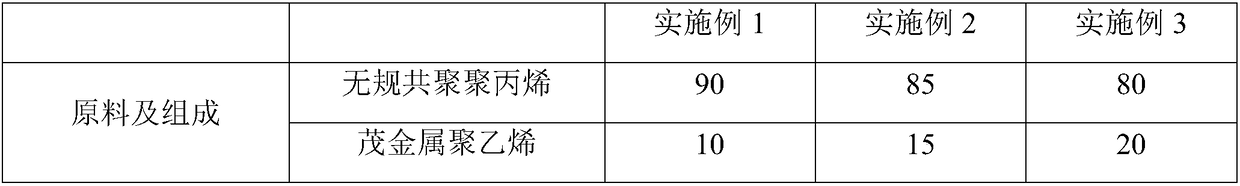

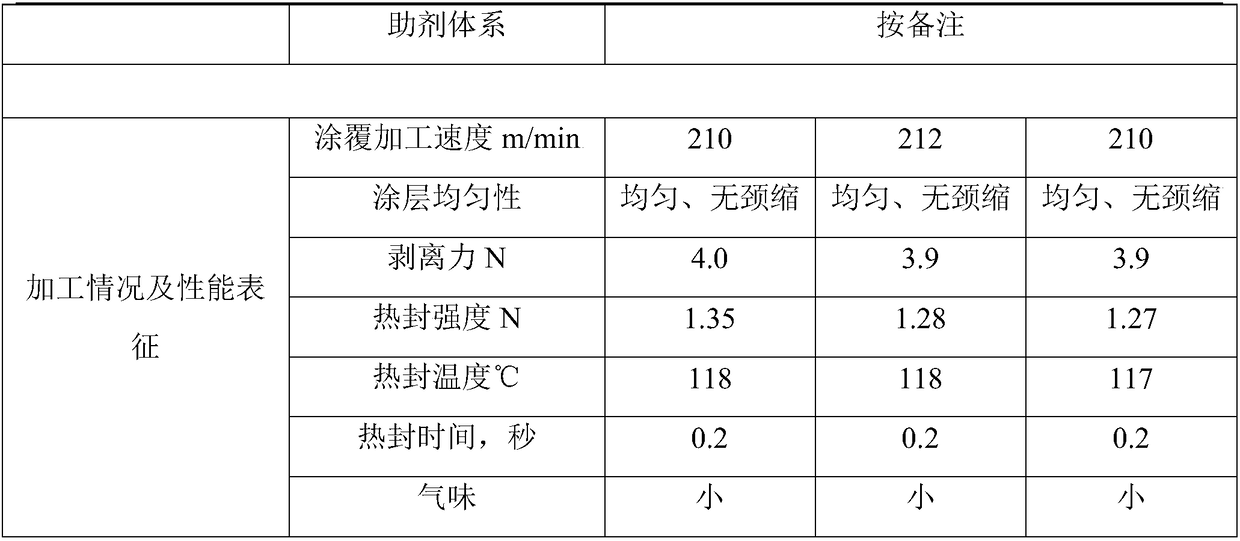

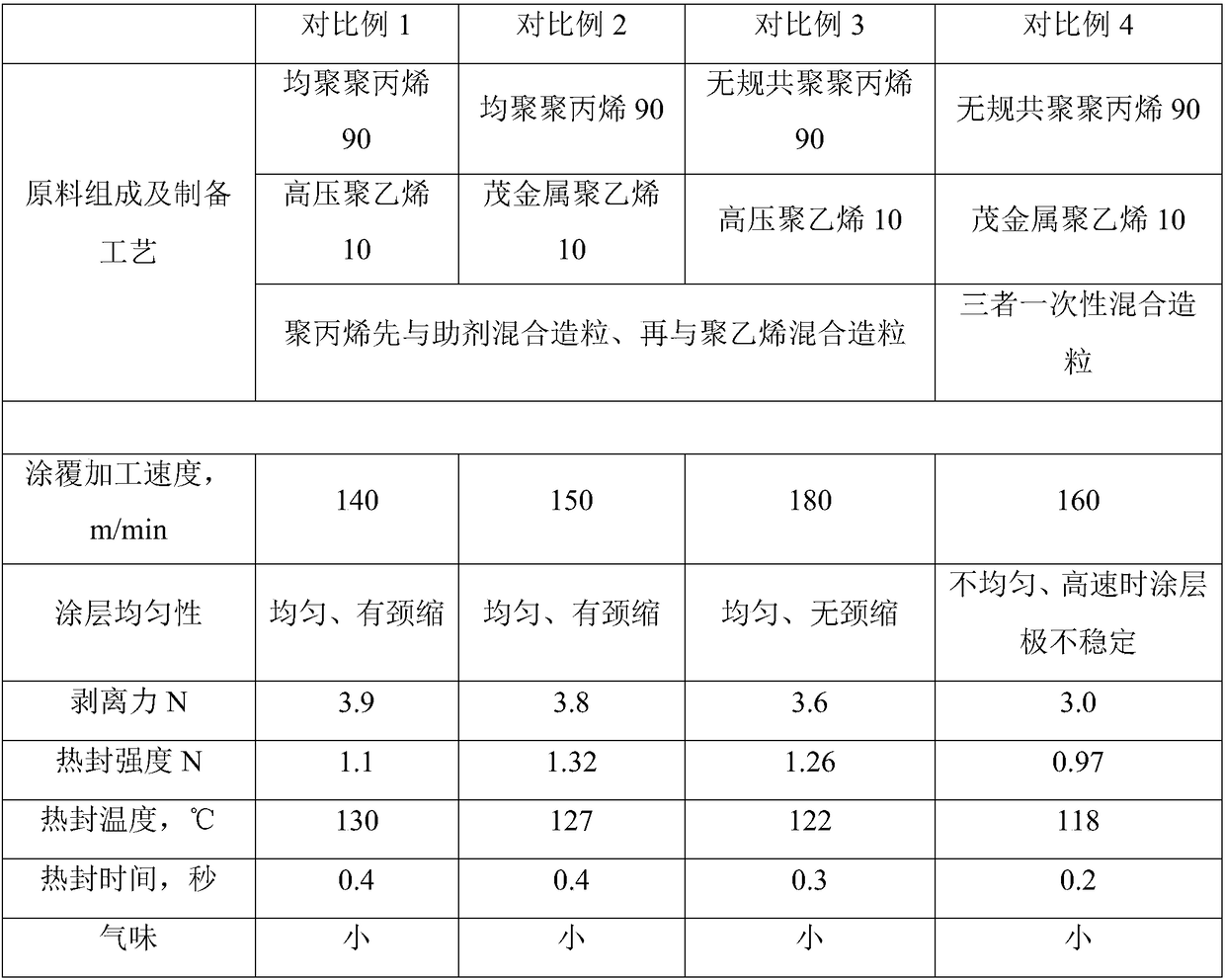

[0020] See Table 1 for the raw material composition of Examples 1-3, and see Table 1 for the processing and performance of the present invention coated on BOPP film.

[0021] The molecular weight distribution of the random copolymerized polypropylene used is 3.8, the MFR is 31 g / 10min, and the amount of comonomer ethylene is 4.2%; the MFR of the metallocene polyethylene used is 1.8 g / 10min, and the molecular weight distribution is 3.6. The preparation method is as follows: firstly mix the random copolymerized polypropylene and the auxiliary agent system, then extrude and granulate, then mix it with metallocene polyethylene evenly, and then extrude and granulate through twin-screw to obtain the coated polypropylene combination described in the invention thing.

[0022] Judging from the effects of the examples, the present invention greatly improves the coating processing speed, coating uniformit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com