A kind of polyester with random hybridization of amide structure and its preparation method

A technology of polyester and amide, which is applied in the field of polyester with random hybridization of amide structure and its preparation. It can solve the problems of film stretching difficulty, operator health injury, rigidity increase and flexibility weakening, etc., and achieve mechanical strength and size Good stability, improved hydrolysis resistance and flexibility, and improved hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

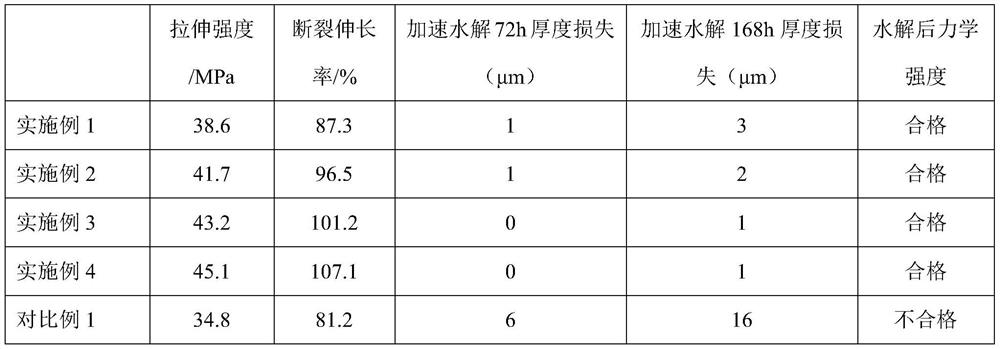

Examples

Embodiment 1

[0032] A kind of polyester that utilizes amide structure to carry out random hybridization and preparation method thereof, comprises the following steps:

[0033] (1) 1329g terephthalic acid, 236g ethylene glycol, 0.6g ethylene glycol antimony catalyst, 2g silicon dioxide antimony agent and 1g trimethyl phosphate stabilizer were weighed and mixed evenly, and added to a 5L reaction kettle, Stir, introduce nitrogen to exhaust oxygen, repeat 3 times, then pressurize and heat up to carry out preliminary esterification reaction, the reaction temperature is maintained at 240-260°C, and the pressure in the kettle is maintained at about 400kPa.

[0034] (2) After the preliminary esterification reaction finishes, close the process tower valve, add 46.5g hexamethylenediamine and 236g ethylene glycol from the hopper, after deoxygenation, add in the kettle and carry out the secondary esterification reaction, the reaction temperature is at 220- 250°C. After the secondary esterification re...

Embodiment 2

[0038] A kind of polyester that utilizes amide structure to carry out random hybridization and preparation method thereof, comprises the following steps:

[0039] (1) 1329g terephthalic acid, 224g ethylene glycol, 0.8g ethylene glycol antimony catalyst, 3g silicon dioxide antimony agent and 1g trimethyl phosphate stabilizer were weighed and mixed evenly, and added to a 5L reaction kettle, Stir, introduce nitrogen to exhaust oxygen, repeat 3 times, then pressurize and heat up to carry out preliminary esterification reaction, the reaction temperature is maintained at 240-260°C, and the pressure in the kettle is maintained at about 400kPa.

[0040] (2) After the preliminary esterification reaction finishes, close the process tower valve, add 93g hexamethylenediamine and 224g ethylene glycol from the hopper, after deoxygenation, add in the kettle and carry out the secondary esterification reaction, the reaction temperature is at 220-250 ℃. After the secondary esterification react...

Embodiment 3

[0044] A kind of polyester that utilizes amide structure to carry out random hybridization and preparation method thereof, comprises the following steps:

[0045] (1) Weigh 1329g terephthalic acid, 211g ethylene glycol, 1g ethylene glycol antimony catalyst, 3g silicon dioxide antimony agent and 2g trimethyl phosphate stabilizer and mix well, add to 5L reaction kettle, stir , introduce nitrogen to exhaust oxygen, repeat 3 times, then pressurize and heat up to carry out preliminary esterification reaction, the reaction temperature is maintained at 240-260°C, and the pressure in the kettle is maintained at about 400kPa.

[0046] (2) After the initial esterification reaction, close the valve of the process tower, add 140g of hexamethylenediamine and 211g of ethylene glycol from the hopper, after deoxygenation, add it to the kettle for secondary esterification, and the reaction temperature is 220-250 ℃. After the secondary esterification reaction is completed, the pressure in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com