CsPbX3 quantum dot room temperature synthetic method

A technology of room temperature synthesis and quantum dots, which is applied in the field of room temperature synthesis of CsPbX3 quantum dots, and can solve problems such as the need for an inert gas environment, poor application effect of electroluminescent devices, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

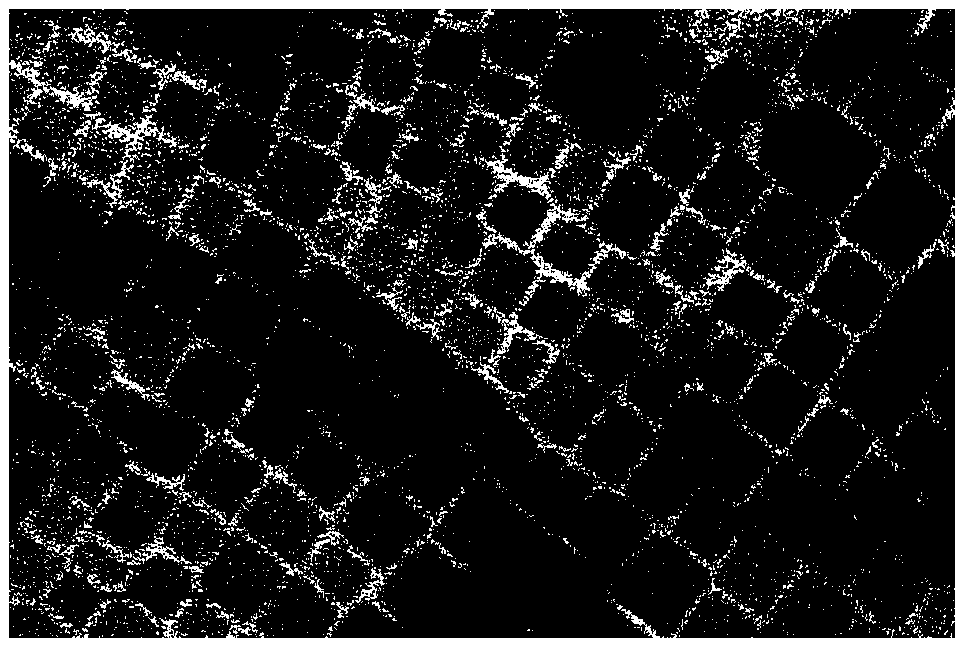

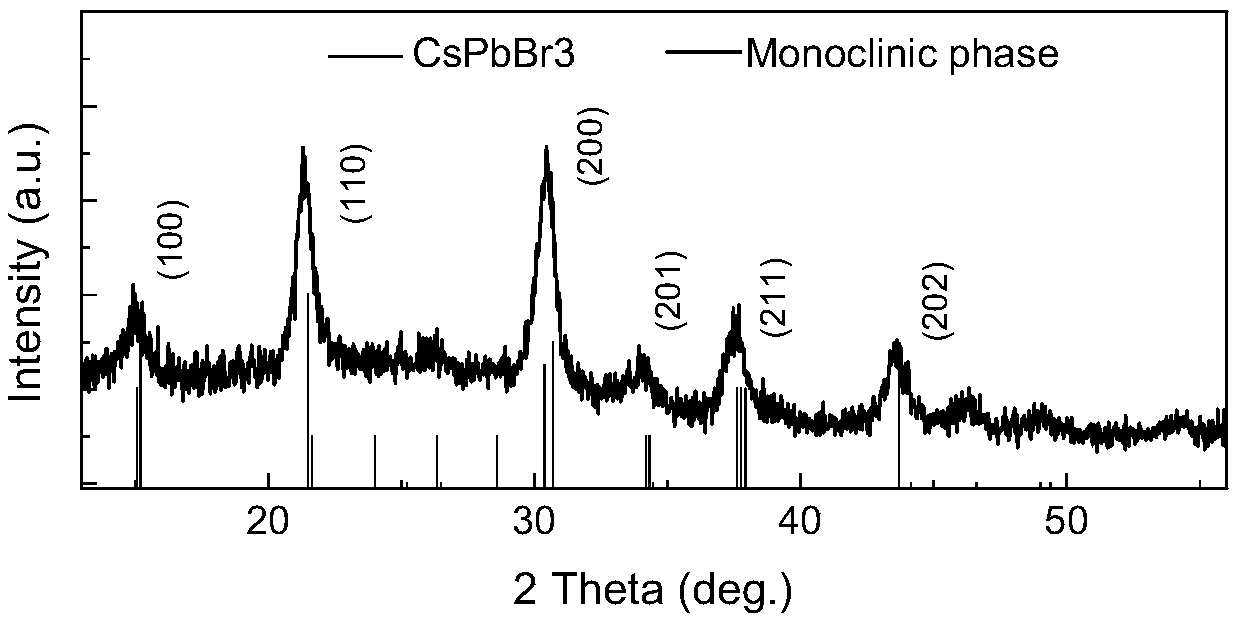

Image

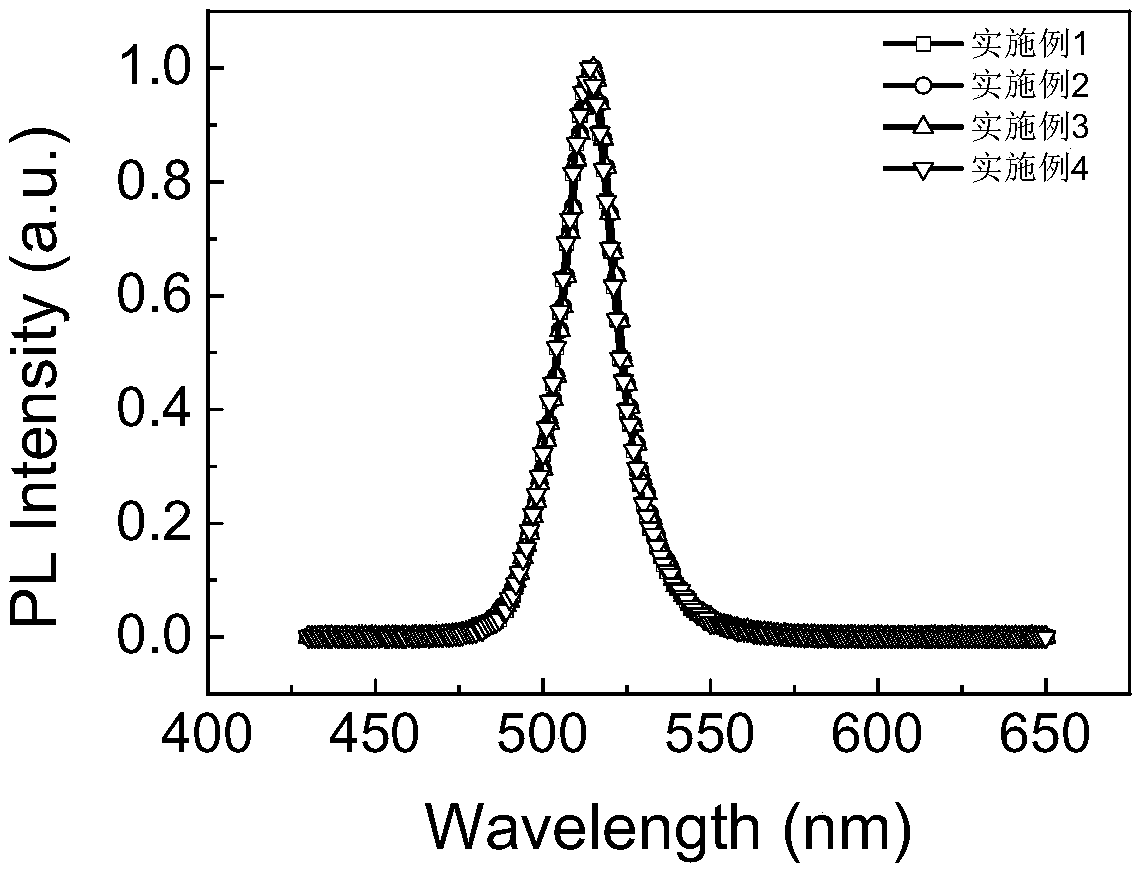

Examples

Embodiment 1

[0030] 1) Dissolve 1.2mmol of cesium carbonate in 3mL of octanoic acid to form a cesium precursor;

[0031] 2) 2 mmol of lead bromide and 4.4 mmol of tetra-n-octyl ammonium bromide were mixed in 30 mL of toluene and stirred in air at room temperature until completely dissolved to obtain a lead precursor;

[0032] 3) ultrasonically dissolve 0.6mmol DDAB in 10mL toluene;

[0033] 4) Inject the cesium precursor into the lead precursor, react for 3 minutes, add the DDAB solution in step 3), and continue stirring for 2 minutes to obtain CsPbBr 3 Quantum dot stock solution;

[0034] 5) Add 60mL ethyl acetate to the quantum dot stock solution and centrifuge to discard the supernatant, and disperse the precipitate in 10mL n-octane to obtain CsPbBr 3 quantum dots.

[0035] Application: Sequential spin coating of PEDOT:PSS, PTAA and CsPbBr on glass substrate with ITO electrodes 3 Quantum dots, and then sequentially evaporate 40nm TPBi, 1nm LiF and 100nm Al electrodes in a thermal ev...

Embodiment 2

[0037] Using the same process as in Example 1, the difference is that octanoic acid is changed to hexanoic acid in step 1) of Example 1, and other conditions remain the same.

Embodiment 3

[0039] Adopt the same process of embodiment 1, the difference is that tetra-n-octyl ammonium bromide is changed into tetrahexyl ammonium bromide in step 2) of embodiment 1, and other conditions remain the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com