Preparation method of lithium battery negative electrode multilayer hollow tin oxide material

A tin oxide and lithium battery technology, applied in tin oxide, battery electrodes, nanotechnology for materials and surface science, etc., can solve the problem of affecting high rate charge and discharge performance, low conductivity of metal oxides, capacity fading, etc. Problems, to achieve the effect of facilitating the doping of conductive particles, reducing mobility and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

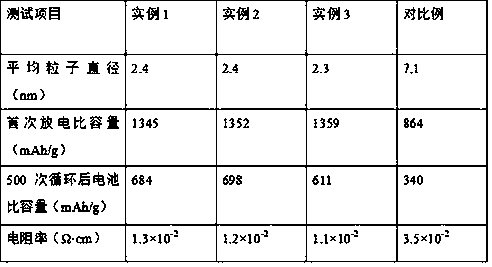

example 1

[0026] In parts by weight, take 20 parts of titanium dioxide and 40 parts of deionized water and add them to the hydrothermal reactor, stir at a speed of 200r / min, adjust the pH of the solution to 2.2 with a mass fraction of 20% sulfuric acid solution, and control the temperature of the reactor At 60°C, add 30 parts of a mixed solution of tin tetrachloride and antimony trichloride dropwise under stirring, wherein the mass ratio of tin tetrachloride and antimony trichloride is 14:1, and the mass fraction of the mixed solution is 15%. , keep warm for 50 minutes to obtain the reaction product; filter the above reaction product, remove the filtrate to obtain a filter cake, wash the filter cake with deionized water until the washing liquid is neutral, place it in an oven with a set temperature of 60°C, and dry 10h, grind the dried filter cake through a 200-mesh sieve, put it into a muffle furnace, heat up to 750°C, and calcinate for 7h to obtain conductive titanium dioxide powder; w...

example 2

[0028] In parts by weight, take 23 parts of titanium dioxide and 45 parts of deionized water and add them to the hydrothermal reactor, stir at a speed of 250r / min, adjust the pH of the solution to 2.3 with a mass fraction of 20% sulfuric acid solution, and control the temperature of the reactor At 63°C, 33 parts of a mixed solution of tin tetrachloride and antimony trichloride were added dropwise under stirring, wherein the mass ratio of tin tetrachloride and antimony trichloride was 14:1, and the mass fraction of the mixed solution was 15%. , heat preservation reaction for 55min, to obtain the reaction product; filter the above reaction product, remove the filtrate to obtain the filter cake, wash the filter cake with deionized water until the washing liquid is neutral, put it in an oven with a set temperature of 65°C, and dry 11h, grind the dried filter cake through a 200-mesh sieve, put it into a muffle furnace, heat up to 775°C, and calcinate for 7h to obtain conductive tita...

example 3

[0030] In parts by weight, take 25 parts of titanium dioxide and 50 parts of deionized water and add them to the hydrothermal reactor, stir at a speed of 300r / min, adjust the pH of the solution to 2.5 with a mass fraction of 20% sulfuric acid solution, and control the temperature of the reactor At 65°C, add 35 parts of a mixed solution of tin tetrachloride and antimony trichloride dropwise under stirring, wherein the mass ratio of tin tetrachloride and antimony trichloride is 14:1, and the mass fraction of the mixed solution is 15% , keep warm for 60 minutes to obtain the reaction product; filter the above reaction product, remove the filtrate to obtain a filter cake, wash the filter cake with deionized water until the washing liquid is neutral, place it in an oven with a set temperature of 70°C, and dry 12h, grind the dried filter cake through a 200-mesh sieve, put it into a muffle furnace, heat up to 800°C, and calcinate for 8h to obtain conductive titanium dioxide powder; we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com