Laser processing method on the surface of ceramic products and ceramic products

A technology for ceramic products and processing methods, which is applied in manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve problems such as deep processing depth, and achieve the effect of shallow processing depth and good touch feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

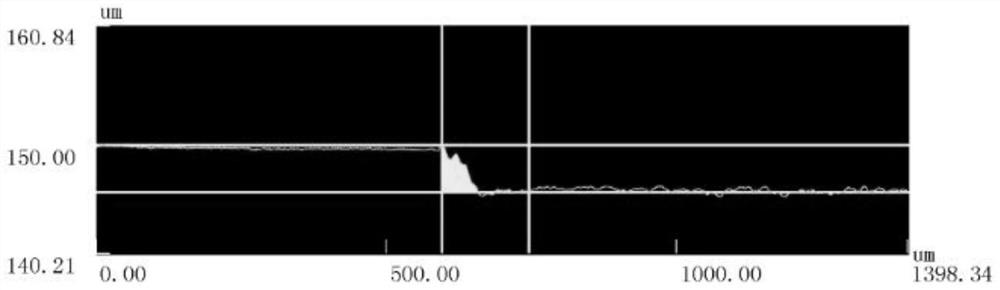

Image

Examples

Embodiment 1

[0025] A laser processing method on the surface of a ceramic product of the present embodiment comprises the following steps:

[0026] Step 1, wipe the aluminum oxide ceramic products with alcohol and then air dry;

[0027] Step 2: Edit the character outline image file that needs to be lasered in CorelDraw, export the image file in the format of PLT, import it into the laser laser system (marking software), and set the process parameters in the laser laser system;

[0028] Step 3, fix the alumina ceramic product in the horizontal support, set the wavelength of the ultrafast laser to 1064nm, the pulse width to 15ps, the filling interval to 0.03mm, the repetition frequency to 50KHZ, and the laser power to 40% in the marking software. Put the focus on the surface of the ceramic product; first, set the marking speed to 1000mm / s in the marking software, and use a single pulse to perform rough engraving on the surface of the alumina ceramic, and laser the appearance of the character...

Embodiment 2

[0035] A laser processing method on the surface of a ceramic product of the present embodiment comprises the following steps:

[0036] Step 1, wipe the zirconia ceramic products with alcohol and then air dry;

[0037] Step 2: Edit the character outline image file that needs to be lasered in CAD, export the image file in DXF format, import it into the laser laser system (marking software), and set the process parameters in the laser laser system;

[0038] Step 3, fix the zirconia ceramic product in the horizontal support, set the wavelength of the ultrafast laser to 1030nm, the pulse width to 20ps, the filling interval to 0.005mm, the repetition frequency to 300KHZ, and the laser power to 25% in the marking software. Put the focus on the surface of the ceramic product; first set the marking speed in the marking software to 800mm / s, and use a single pulse to perform rough engraving on the surface of the zirconia ceramic, and laser the appearance of the characters, and the bottom...

Embodiment 3

[0042] A laser processing method on the surface of a ceramic product of the present embodiment comprises the following steps:

[0043] Step 1, wipe the silicon nitride ceramic products with alcohol and then air dry;

[0044] Step 2: Edit the character outline image file that needs to be lasered in CAD, export the image file in DXF format, import it into the laser laser system (marking software), and set the process parameters in the laser laser system;

[0045]Step 3, fix the silicon nitride ceramic product in the horizontal support, set the wavelength of the ultrafast laser to 1045nm, the pulse width to 25ps, the filling spacing to 0.08mm, the repetition frequency to 1000KHZ, and the laser power to 28% in the marking software , put the focus on the surface of the ceramic product; first set the marking speed in the marking software to 1200mm / s, use the single pulse method to carry out rough engraving on the surface of the silicon nitride ceramic product, and laser out the appe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com