Three-shell iron-silicon-substrate soft magnet composite material and manufacturing method thereof

A soft magnetic composite material, three-shell technology, applied in the fields of inorganic material magnetism, metal processing equipment, transportation and packaging, etc., can solve the problems of high energy and raw material loss, complex preparation process, unfavorable mass preparation, etc., and achieve constant conductance. The effect of good magnetic properties, good chemical stability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

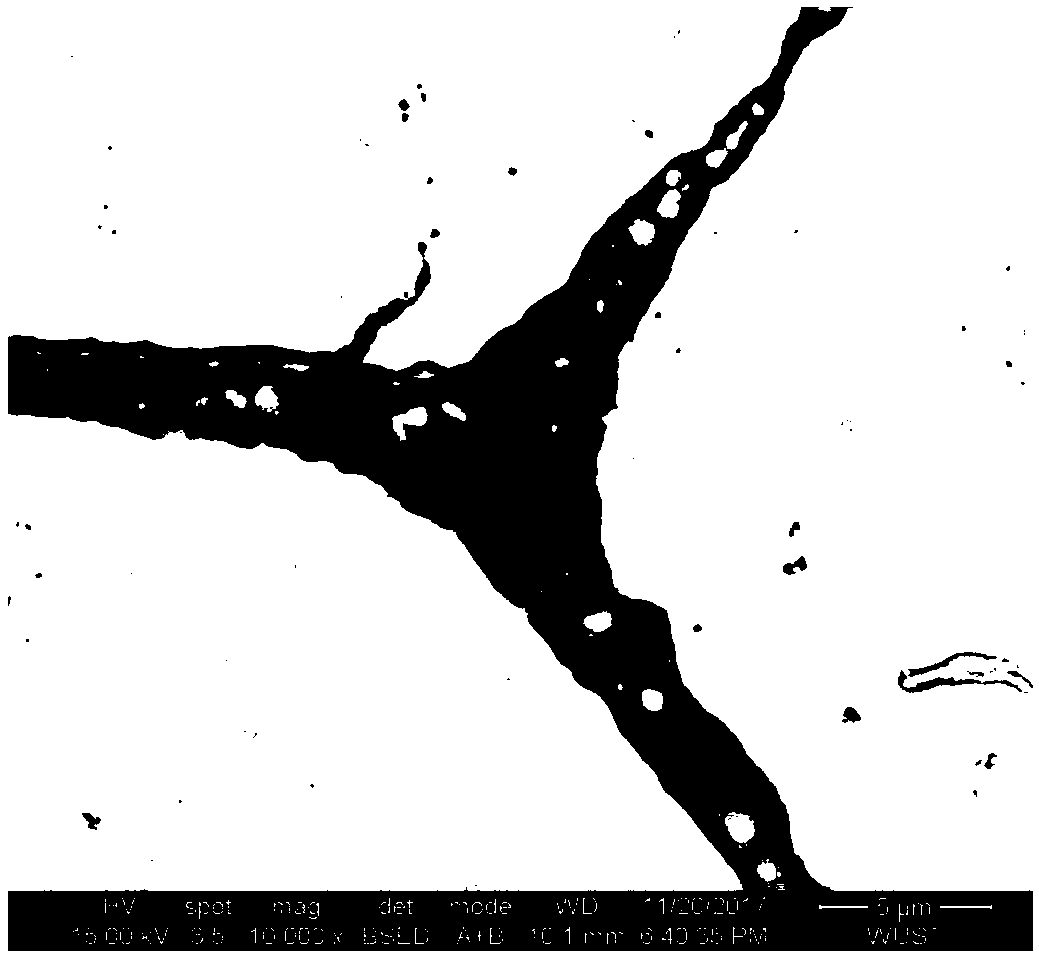

Image

Examples

Embodiment 1

[0033] A three-shell iron-silicon-based soft magnetic composite material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0034] The first step, composite powder preparation

[0035] According to the iron-silicon alloy powder:water mass ratio of 1:(5-40), the iron-silicon alloy powder is placed in the water, stirred at a water temperature of 30-60°C for 5-10 hours, and solid-liquid separation, A composite powder is obtained.

[0036] The second step, cold forming

[0037] The composite powder is vacuum-dried, loaded into a mold, and cold-pressed under the condition of 300-600 MPa to obtain a green body.

[0038] The third step, sintering

[0039] The green body is placed in a high-temperature sintering furnace, heated to 800-900° C. under vacuum conditions, and sintered for 0.5-1 hour to obtain a sintered green body.

[0040] The fourth step, heat treatment

[0041] The sintered green body is placed in a heat treat...

Embodiment 2

[0046] A three-shell iron-silicon-based soft magnetic composite material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0047] The first step, composite powder preparation

[0048] According to the iron-silicon alloy powder:water mass ratio of 1:(20-55), the iron-silicon alloy powder is placed in the water, stirred at a water temperature of 35-65°C for 10-15 hours, and solid-liquid separation, A composite powder is obtained.

[0049] The second step, cold forming

[0050] The composite powder is vacuum-dried, loaded into a mold, and cold-pressed under the condition of 450-750 MPa to obtain a green body.

[0051] The third step, sintering

[0052] The green body is placed in a high-temperature sintering furnace, heated to 900-1000° C. under vacuum conditions, and sintered for 1.5-2 hours to obtain a sintered green body.

[0053] The fourth step, heat treatment

[0054] The sintered green body is placed in a heat tre...

Embodiment 3

[0059] A three-shell iron-silicon-based soft magnetic composite material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0060] The first step, composite powder preparation

[0061] According to the iron-silicon alloy powder:water mass ratio of 1:(35-70), the iron-silicon alloy powder is placed in the water, stirred at a water temperature of 40-70°C for 15-20h, and solid-liquid separation, A composite powder is obtained.

[0062] The second step, cold forming

[0063] The composite powder is vacuum-dried, loaded into a mold, and cold-pressed under the condition of 600-900 MPa to obtain a green body.

[0064] The third step, sintering

[0065] The green body is placed in a high-temperature sintering furnace, heated to 1000-1100° C. under protective atmosphere conditions, and sintered for 2.5-3 hours to obtain a sintered green body.

[0066] The fourth step, heat treatment

[0067] The sintered green body is placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com