A graphite oxide phase monolayer c 3 no 4 Composite membrane material and its preparation method and application

A technology of C3N4 and graphite phase, which is applied in the field of graphite oxide phase single-layer C3N4 composite membrane material and its preparation, can solve the problems of limited application and no visible light response, and achieve the effect of increased contact area and excellent recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

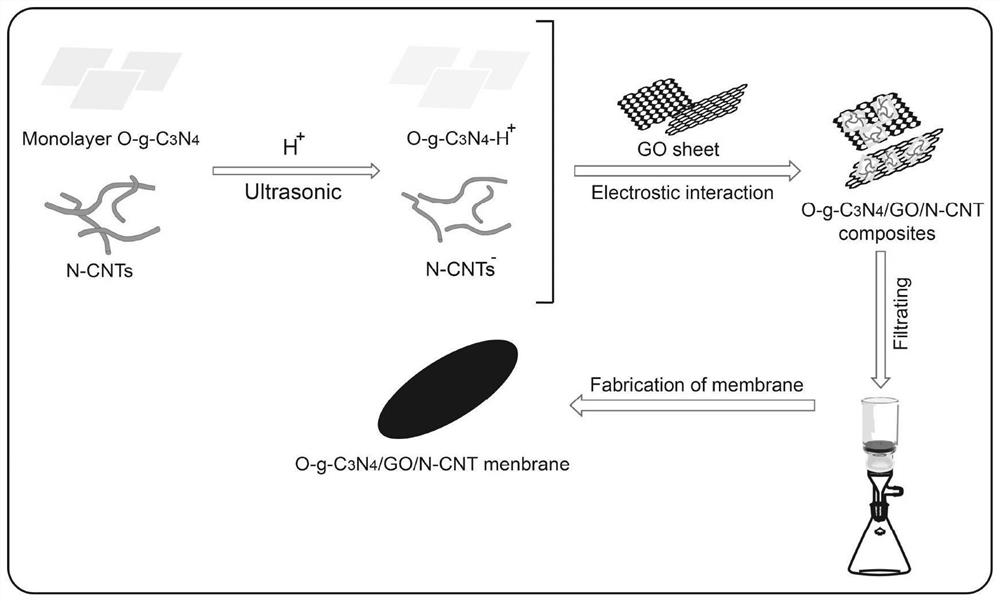

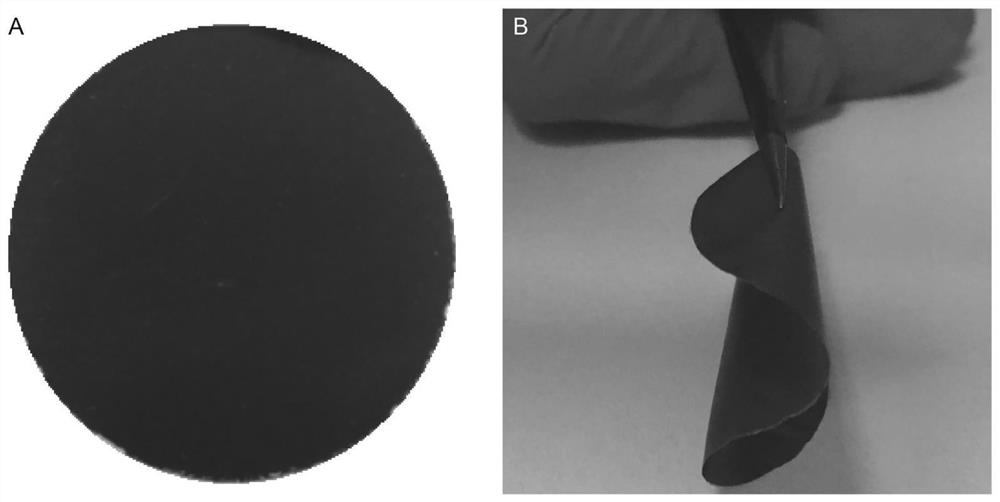

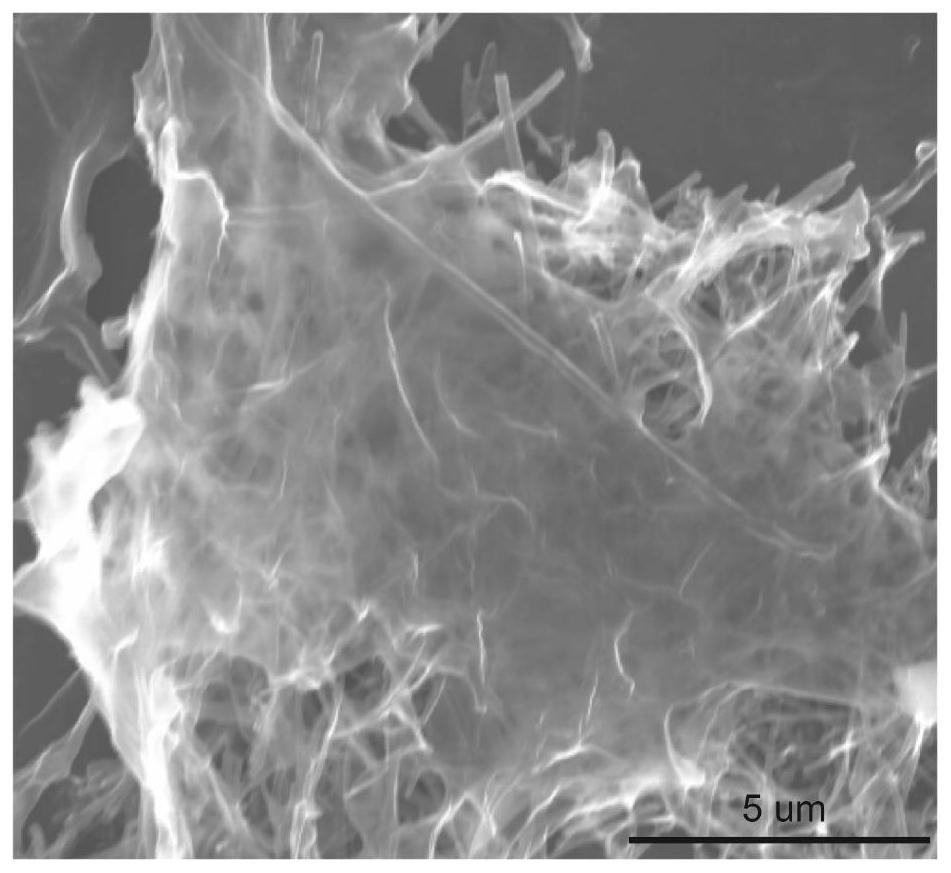

[0026] Such as figure 1 As shown, a graphite oxide phase monolayer C 3 N 4 The preparation method of composite membrane material comprises the following steps: weighing O-g-C 3 N 4 and N-CNT in two centrifuge tubes, respectively added concentrated hydrochloric acid, ultrasonic 90min. O-g-C treated with concentrated hydrochloric acid 3 N 4 Mix with N-CNT in the same centrifuge tube, centrifuge, wash 3 times with water, and keep the precipitate. Add GO, mix and sonicate for 2h to obtain a mixed solution. Install the suction filtration device, take the mixed solution for suction filtration, take it out after suction filtration, dry, add ethanol solution dropwise on the back of the filter membrane, and mix O-g-C 3 N 4 / GO / N-CNT membrane was peeled off from the filter membrane, and finally a graphite oxide phase monolayer C 3 N 4 Composite membrane materials such as figure 2 , image 3 shown. from figure 2 It can be seen from the optical pictures that the film can b...

Embodiment 1

[0031] Example 1: Graphite Oxide Phase Monolayer C 3 N 4 Application of composite membrane materials in photocatalytic degradation of antibiotic molecules in water. Accurately take 20mL of tetracycline hydrochloride solution with a concentration of 10mg / L in the quartz photoreactor, take a sample of 0.5mL and mark it as -30 in a 1.5mL centrifuge tube, then add graphite oxide phase monolayer C into the reactor 3 N 4 Composite membrane material, take a sample of 0.5mL in a 1.5mL centrifuge tube after ventilating and stirring for 30min in a dark place, and mark it as 0. Turn on the circulating condensate device and the xenon lamp light source in turn (there is a 400nm filter at the xenon lamp light source), start the photocatalytic reaction process, take 0.5mL samples every 30min and put them in a 1.5mL centrifuge tube and mark them, and the photoreaction ends when it reaches 360min . The sample was centrifuged at 10000r / min for 30min, and the absorbance of tetracycline hydro...

Embodiment 2

[0038] Example 2: Graphite Oxide Phase Monolayer C 3 N 4 Application of composite membrane material in photocatalytic degradation of organic dye pollutant molecules in water body. Accurately take 20mL of rhodamine 6G solution with a concentration of 10mg / L in the quartz photoreactor, take a sample of 0.5mL and mark it as -30 in a 1.5mL centrifuge tube, and then add graphite oxide phase monolayer C into the reactor 3 N 4 Composite membrane material, take a sample of 0.5mL in a 1.5mL centrifuge tube after ventilating and stirring for 30min in a dark place, and mark it as 0. Turn on the circulating condensate device and the xenon lamp light source in turn (there is a 400nm filter at the xenon lamp light source), start the photocatalytic reaction process, take 0.5mL samples every 30min and put them in a 1.5mL centrifuge tube and mark them, and the photoreaction ends when it reaches 360min . The sample was centrifuged at 10000r / min for 30min, and the absorbance of rhodamine 6G ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com