An amphiphilic adsorption type thiol-modified nano-hydroxyapatite adsorbent and its preparation method and application

A nano-hydroxyapatite, adsorption-type technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of not considering the interaction between heavy metals and rare earth elements, and not suitable for the treatment of heavy metals and rare earths Element complex pollution and other problems, to achieve the effect of low engineering cost, reduce energy consumption and resource consumption, and reduce pollution treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

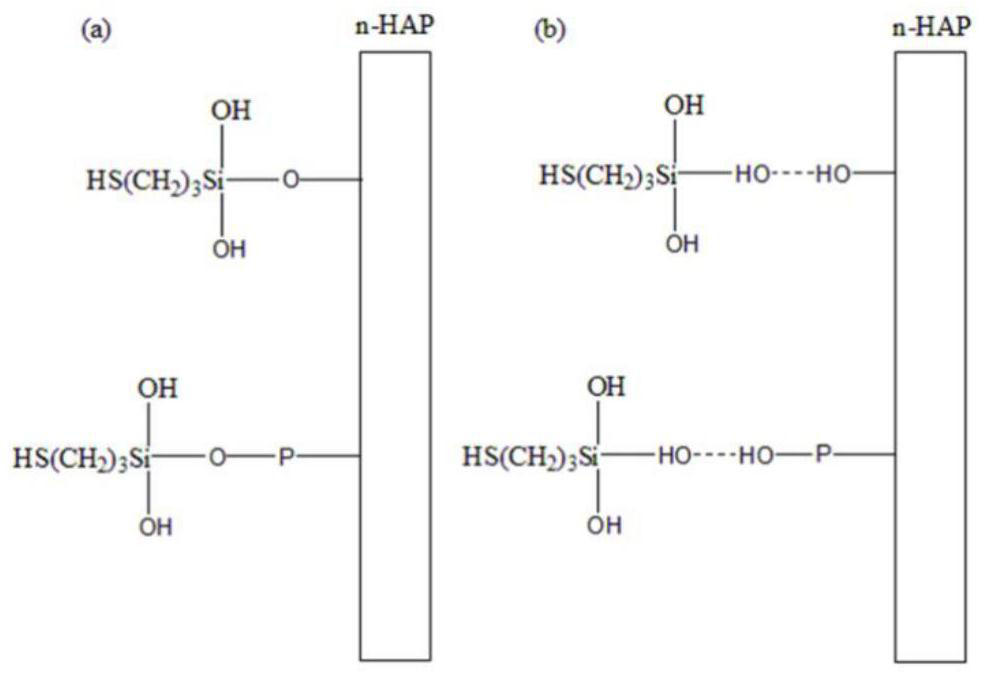

[0035] Preparation of amphiphilic adsorption type thiol-modified nano-hydroxyapatite adsorbent:

[0036] (1) Prepare an ethanol-water mixed solution with a volume ratio of 1:3, and slowly add acetic acid buffer dropwise to adjust the pH value to 4;

[0037] (2) Take ethanol-water solution and add silane coupling agent KH-590, hydrolyze at room temperature for 30min under the condition of pH 4, and prepare 10ml KH-590 hydrolysis solution;

[0038] (3) Take ethanol-water solution preparation concentration and be 40ml nano-hydroxyapatite (n-HAP) slurry of 125g / L, ultrasonic dispersion 30min; Then add step (2) 10mL KH-590 hydrolysis solution wherein, make KH- The mass ratio of 590 to n-HAP is 1:2, stir at 60°C for 90 minutes, evaporate to dryness at 80°C; and ensure that the pH of the reaction system needs to be controlled at about 4 throughout;

[0039] (4) washing with ethanol and water for 5 times in sequence, drying in an oven at 80°C for 24 hours, cooling, and grinding to ob...

Embodiment 2

[0042] Preparation of amphiphilic adsorption type thiol-modified nano-hydroxyapatite adsorbent:

[0043] (1) Prepare an ethanol-water mixed solution with a volume ratio of 1:9, and slowly add acetic acid buffer dropwise to adjust the pH value to 4;

[0044] (2) Take ethanol-water solution and add silane coupling agent KH-590, hydrolyze at room temperature for 30min under the condition of pH 4, and prepare 10ml KH-590 hydrolysis solution;

[0045] (3) Take ethanol-water solution and prepare 40ml of nano-hydroxyapatite slurry (n-HAP) with a concentration of 125g / L, and ultrasonically disperse it for 30min; The mass ratio of 590 to n-HAP is 1:10, stirred at 60°C for 90 minutes, and evaporated to dryness at 80°C; and ensure that the pH of the reaction system needs to be controlled at about 4 throughout;

[0046] (4) washing with ethanol and water for 5 times in sequence, drying in an oven at 80°C for 24 hours, cooling, and grinding to obtain the adsorbent;

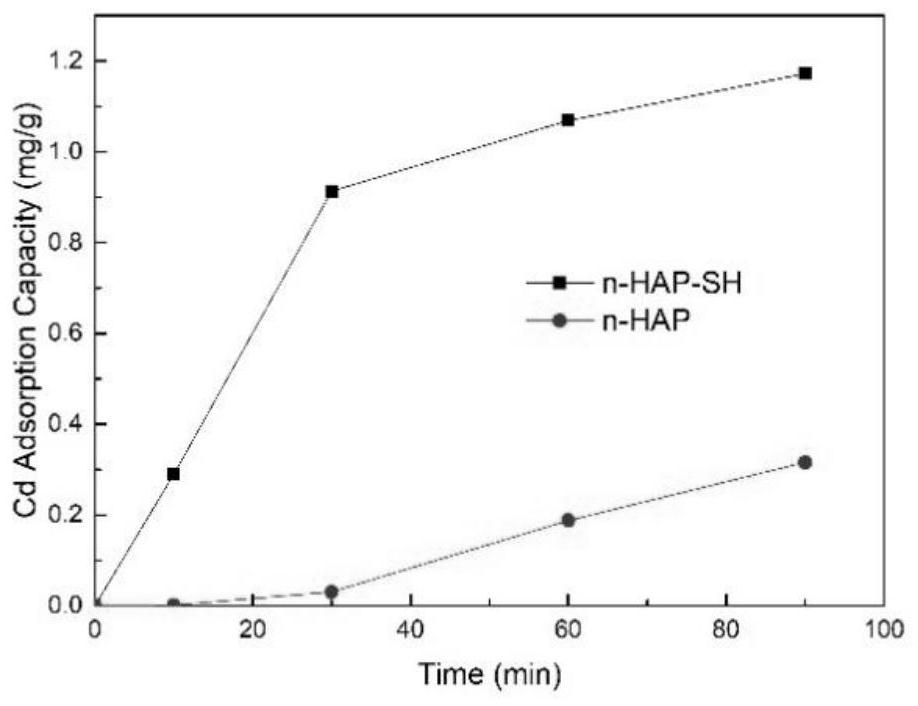

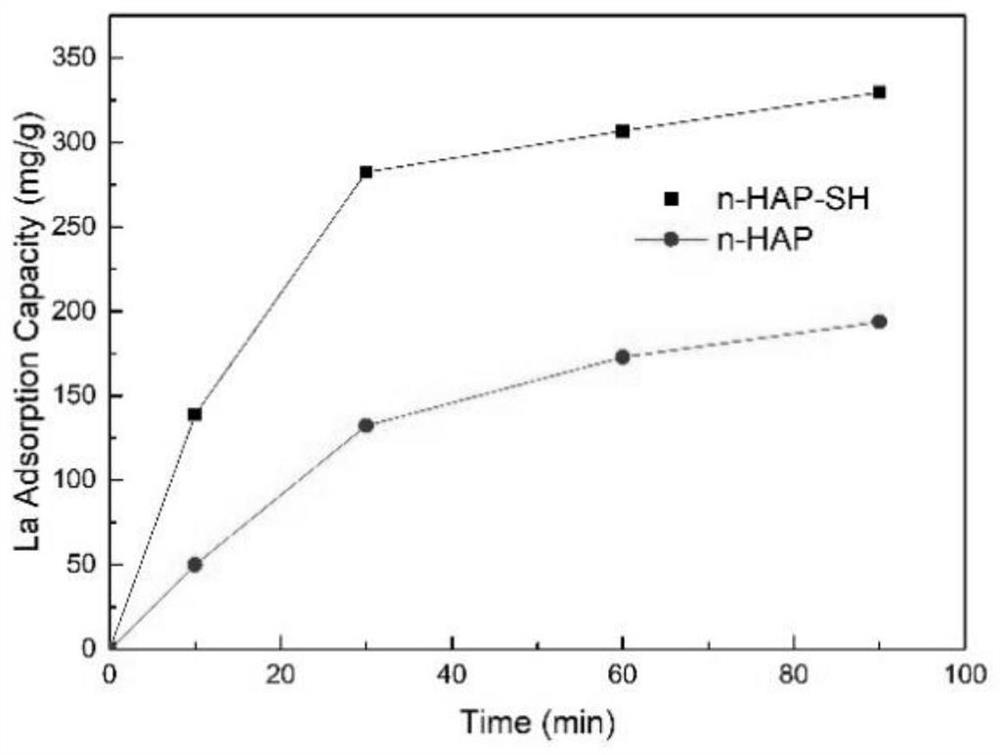

[0047] (5) The prepa...

Embodiment 3

[0049] Preparation of amphiphilic adsorption type thiol-modified nano-hydroxyapatite adsorbent:

[0050] (1) Prepare an ethanol-water mixed solution with a volume ratio of 1:3, and slowly add acetate buffer dropwise to adjust the pH value to 4.

[0051] (2) Take ethanol-water solution and add silane coupling agent KH-590, hydrolyze at room temperature for 30min under the condition of pH 4, and prepare 10ml KH-590 hydrolysis solution;

[0052] (3) Take ethanol-water solution to prepare 40ml nano-hydroxyapatite slurry with a concentration of 125g / L, and ultrasonically disperse it for 30min; The mass ratio is 1:5, stirred at 60°C for 90 minutes, evaporated to dryness at 80°C; and ensure that the pH of the reaction system needs to be controlled to be around 4 throughout the process;

[0053] (4) washing with ethanol and water for 5 times in sequence, drying in an oven at 80°C for 24 hours, cooling, and grinding to obtain the adsorbent;

[0054] (5) The prepared adsorbent is drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com