Customization joint bone cement prosthesis reinforcing supporting frame and preparation and application thereof

A joint bone and bone cement technology, applied in joint implants, joint implants, etc., can solve the problems of low adhesion, increased difficulty in secondary joint surgery, and easy fracture or breakage of bone cement spacers. achieve enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

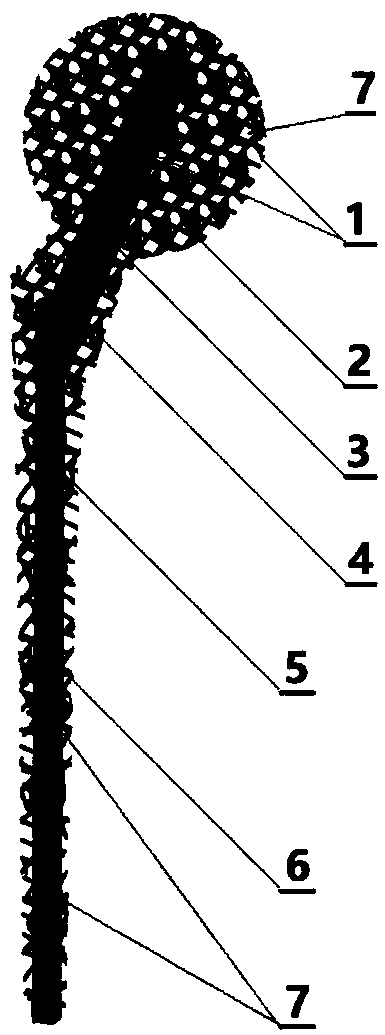

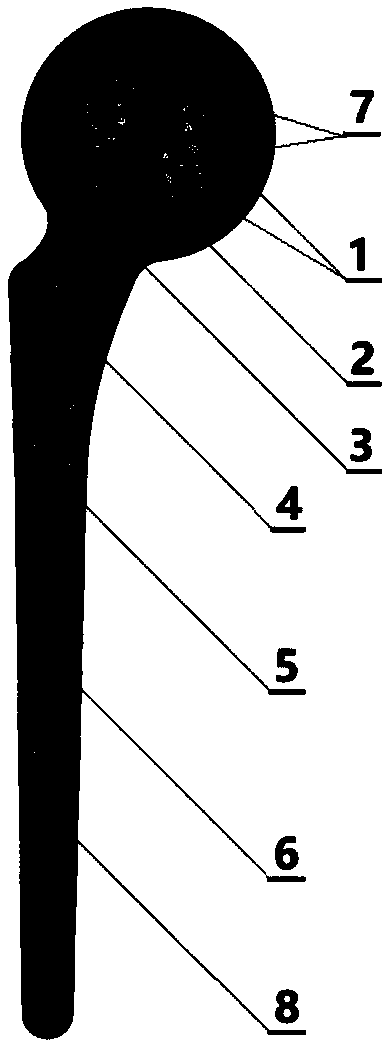

[0040]A personalized joint bone cement prosthesis reinforcement bracket is characterized in that: the reinforcement bracket 1 is provided with a bracket main beam 3, a bracket sub-beam 5 and a bracket net 7, and the bracket net 7 is arranged on the bracket main beam 3 and the bracket sub-beam Around 5, the support main beam 3 is provided with a support head 2 and a support neck 4, and the support subbeam 5 is provided with a support handle 6.

[0041] Further, the material of the support main beam 3 and the support sub-beam 5 is metal.

[0042] Further, the outer diameter of each part of the stent net 7 is smaller than that of the bone cement prosthesis 8 .

Embodiment 2

[0044] A personalized joint bone cement prosthesis reinforcement bracket is characterized in that: the reinforcement bracket 1 is provided with a bracket main beam 3, a bracket sub-beam 5 and a bracket net 7, and the bracket net 7 is arranged on the bracket main beam 3 and the bracket sub-beam Around 5, the support main beam 3 is provided with a support head 2 and a support neck 4, and the support subbeam 5 is provided with a support handle 6.

[0045] Further, the main beam 3 of the bracket and the sub-beam 5 of the bracket are made of polymer plastics.

[0046] Further, the outer diameter of each part of the stent net 7 is equal to the bone cement prosthesis 8 .

Embodiment 3

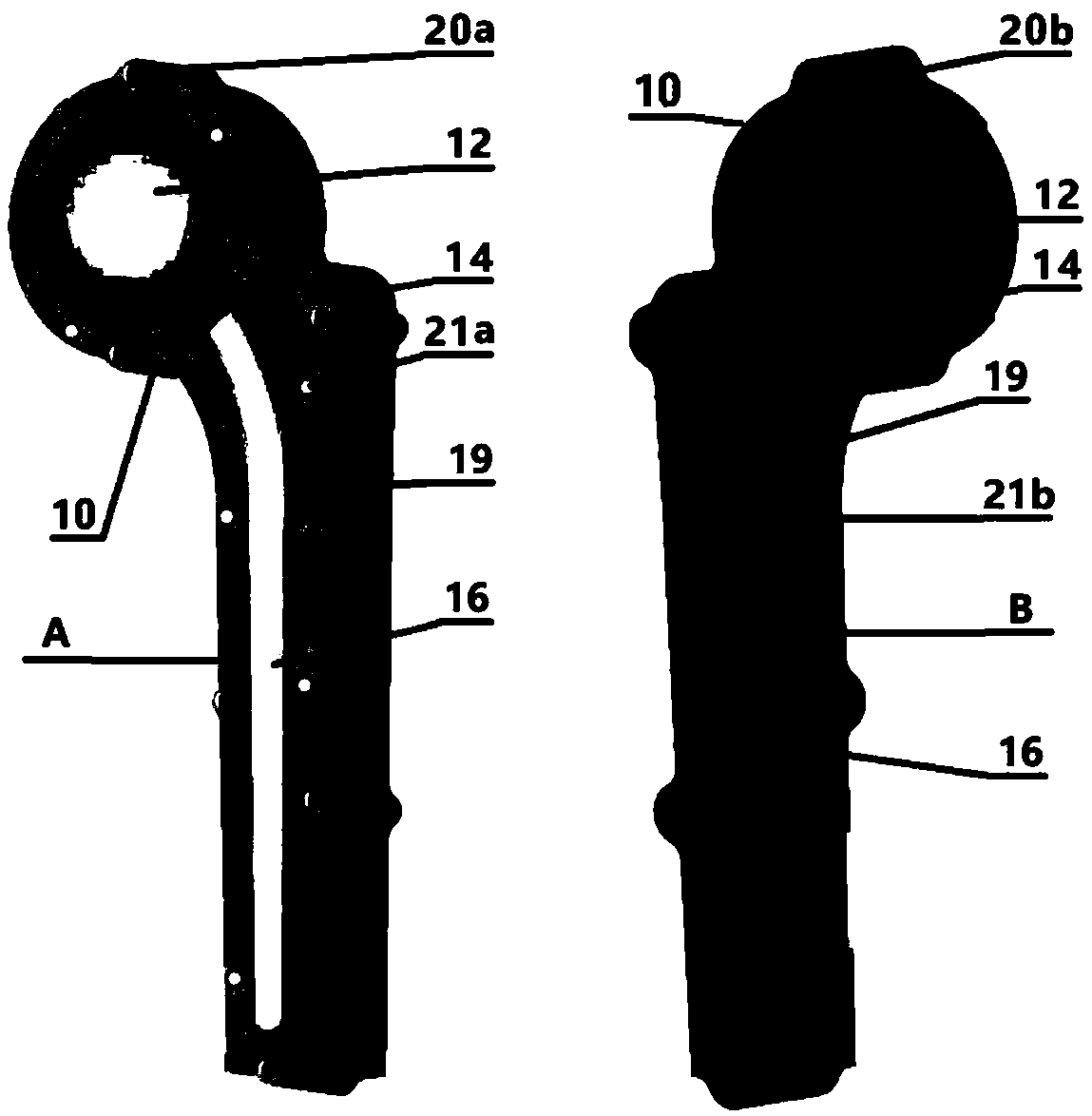

[0048] A preparation of a personalized joint bone cement prosthesis reinforcement bracket, which is characterized in that it includes building a three-dimensional model of a personalized joint bone cement prosthesis, designing a personalized joint bone cement prosthesis mold 10, and manufacturing a personalized joint bone cement prosthesis. Body mold 10. The process of designing a personalized joint bone cement prosthesis reinforcement bracket and manufacturing a personalized joint bone cement prosthesis reinforcement bracket, the operation steps are:

[0049] 1. Construction of personalized three-dimensional model of joint bone cement prosthesis

[0050] Professionals collect CT or X-ray or MR medical image data of the patient's joint parts (including the long bone part of the joint and the bone cement prosthesis handle), according to the anatomical image features and parameters of the specific patient's CT or X-ray or MR medical image data For example, select the diameter, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com