Colloidal electrolyte and battery containing colloidal electrolyte

A technology of colloidal electrolyte and electrolyte salt, applied in water-based electrolytes, secondary batteries, circuits, etc., can solve the problems of difficult to perfuse batteries, affect the performance of batteries, and fast gelation of colloidal electrolytes, and achieve good water retention and strength, electrolyte salts The effect of uniform distribution and convenient perfusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0082] The preparation process of the colloidal electrolyte includes: taking a certain amount of electrolyte salts zinc sulfate and lithium sulfate and dissolving them in solvent water to prepare an aqueous electrolyte A1 containing 2mol / L zinc sulfate and 1mol / L lithium sulfate.

[0083]Take 8mL of aqueous electrolyte A1, add 1mL of silica sol (solid content 30%), and 1mL of additive polystyrene sodium sulfonate aqueous solution (PSS, solid content 30%) to A1, and the mass percentage of PSS in the colloidal electrolyte is 3%.

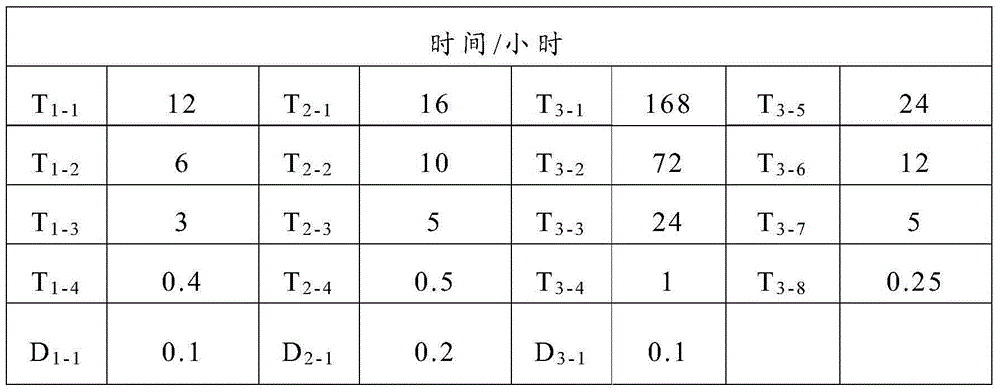

[0084] Record the time T from the aqueous electrolyte to the colloidal electrolyte 1-1 .

Embodiment 1-2

[0086] In Example 1-2, take 8.67mL of aqueous electrolyte A1, add 1mL of silica sol (solid content 30%), and 0.33mL of additive sodium polystyrene sulfonate aqueous solution (solid content 30%) to A1, The mass percentage of PSS in colloidal electrolyte is about 1%. The rest of the colloidal electrolyte preparation process is the same as in Example 1-1.

[0087] Record the time T from the aqueous electrolyte to the colloidal electrolyte 1-2 .

Embodiment 1-3

[0089] In Example 1-3, take 9 mL of aqueous electrolyte A1, add 1 mL of silica sol (solid content 30%), and 0.05 mL of additive polystyrene sodium sulfonate aqueous solution (solid content 30%) to A1, PSS The mass percentage of colloidal electrolyte is about 0.15%. The rest of the colloidal electrolyte preparation process is the same as in Example 1-1.

[0090] Record the time T from the aqueous electrolyte to the colloidal electrolyte 1-3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com