An environmentally friendly large yellow croaker feed that replaces chilled feed throughout the process and its preparation method

A large yellow croaker, chilled technology, applied in animal feed, animal feed, food processing and other directions, can solve the problem of not being able to completely replace chilled fish, and achieve the effects of strengthening liver and kidney immunity, saving labor costs, and growing faster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

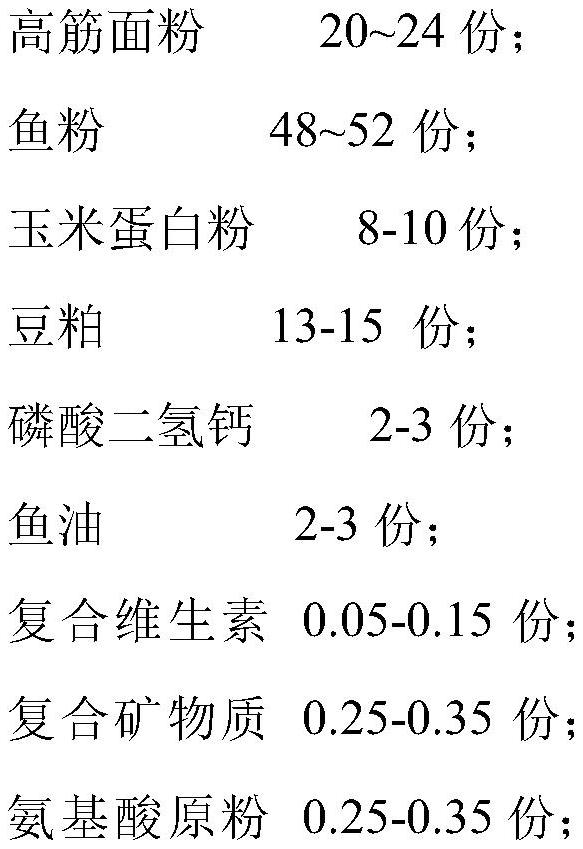

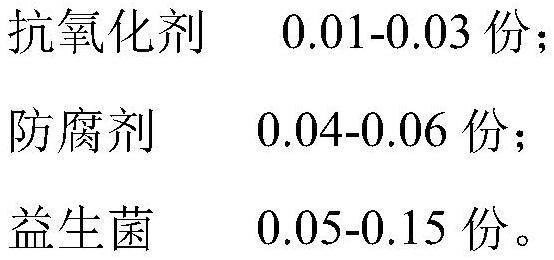

Image

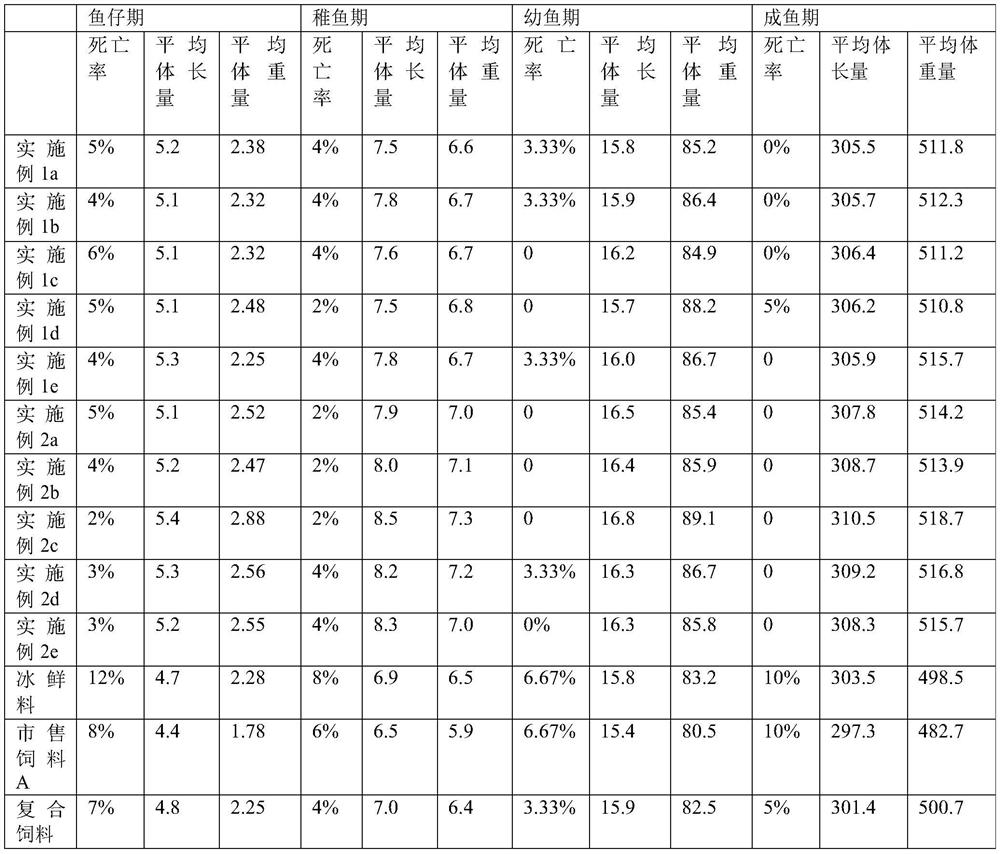

Examples

Embodiment 1a

[0041] A preparation method for an environmentally friendly large yellow croaker feed that replaces chilled feed throughout the whole process, comprising the following steps:

[0042] Step1, use a feed mill to grind 20kg of high-gluten flour, 48kg of fish meal, 8kg of corn gluten meal, 13kg of soybean meal, 2kg of calcium dihydrogen phosphate, 0.05kg of multivitamin, 0.25kg of multivitamin, 0.25kg of raw amino acid powder, and 0.05kg of probiotics After pulverizing and stirring evenly, pass through a 100-mesh sieve to obtain the mixture;

[0043] Step2, put the pulverized mixture into a differential pressure extruder for pre-expansion to obtain a pre-expanded material;

[0044] Step3, mix 2kg of fish oil, 0.01kg of antioxidant, and 0.04kg of preservative evenly, then add it to the pre-expanded material, stir evenly and dry it to obtain the dried material;

[0045] Step4, putting the dried material into the differential pressure extruder again for extruding to obtain the large...

Embodiment 1

[0053] The preparation method of Example 1b-Example 1e is the same as that of Example 1a, the difference is that the components and the specific content of the components of Example 1b-Example 1e are different from Example 1a. See the table below for details (unit: kg):

[0054] Example 1a Example 1b Example 1c Example 1d Example 1e High-gluten flour 20 24 21 22 23 fish meal 48 52 51 49 50 corn protein flour 8 10 8.5 9 9.5 soybean meal 13 15 14 13.5 14.5 Calcium Dihydrogen Phosphate 2 3 2.2 2.8 2.5 multi-vitamins 0.05 0.15 0.10 0.12 0.08 complex minerals 0.25 0.35 0..30 0.32 0.28 Amino Acid Powder 0.25 0.35 0.28 0.30 0.32 Probiotics 0.05 0.15 0.10 0.07 0.12 fish oil 2 3 2.7 2.4 2.1 Antioxidants 0.01 0.03 0.02 0.025 0.015 preservative 0.04 0.06 0.045 0.050 0.055

Embodiment 2a

[0056] A preparation method for an environmentally friendly large yellow croaker feed that replaces chilled feed throughout the whole process, comprising the following steps:

[0057] Step1, use a feed mill to grind 21kg of high-gluten flour, 49kg of fish meal, 9kg of corn gluten meal, 14kg of soybean meal, 3kg of calcium dihydrogen phosphate, 0.06kg of multivitamin, 0.26kg of multivitamin, 0.26kg of amino acid raw powder, and 0.06kg of probiotics After pulverizing and stirring evenly, pass through a 100-mesh sieve to obtain mixture A, pass the mixture A through a 80-mesh sieve to continue screening, and obtain mixture B1 with a particle size between 80-100 mesh and a mixture with a particle size below 80 mesh B2;

[0058] Step2, put the pulverized mixture B1 into a differential pressure extruder for pre-expansion to obtain a pre-expanded material;

[0059] Step3, mix 2kg of fish oil, 0.01kg of antioxidant, 0.04kg of preservative, and 0.69kg of mixture B2 evenly, then add it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com