A bridge damage detection method

A damage detection and bridge technology, applied in the direction of measuring devices, elastic testing, machine/structural component testing, etc., can solve the problems of limited influence of overall characteristics, unsatisfactory structural effects, and infeasibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Aiming at the damage detection method based on the influence line, the numerical simulation dynamic response calculation and analysis of the 2-axle vehicle crossing the bridge are carried out. The vehicle model parameters involved in the calculation are shown in Table 1:

[0126] Table 1. Vehicle parameters for numerical calculation

[0127]

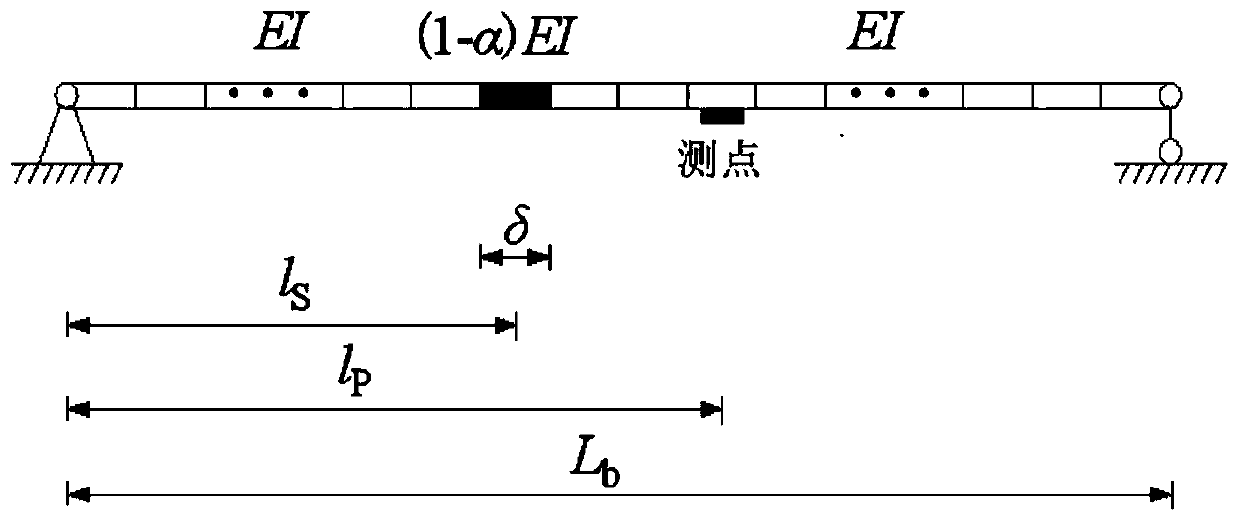

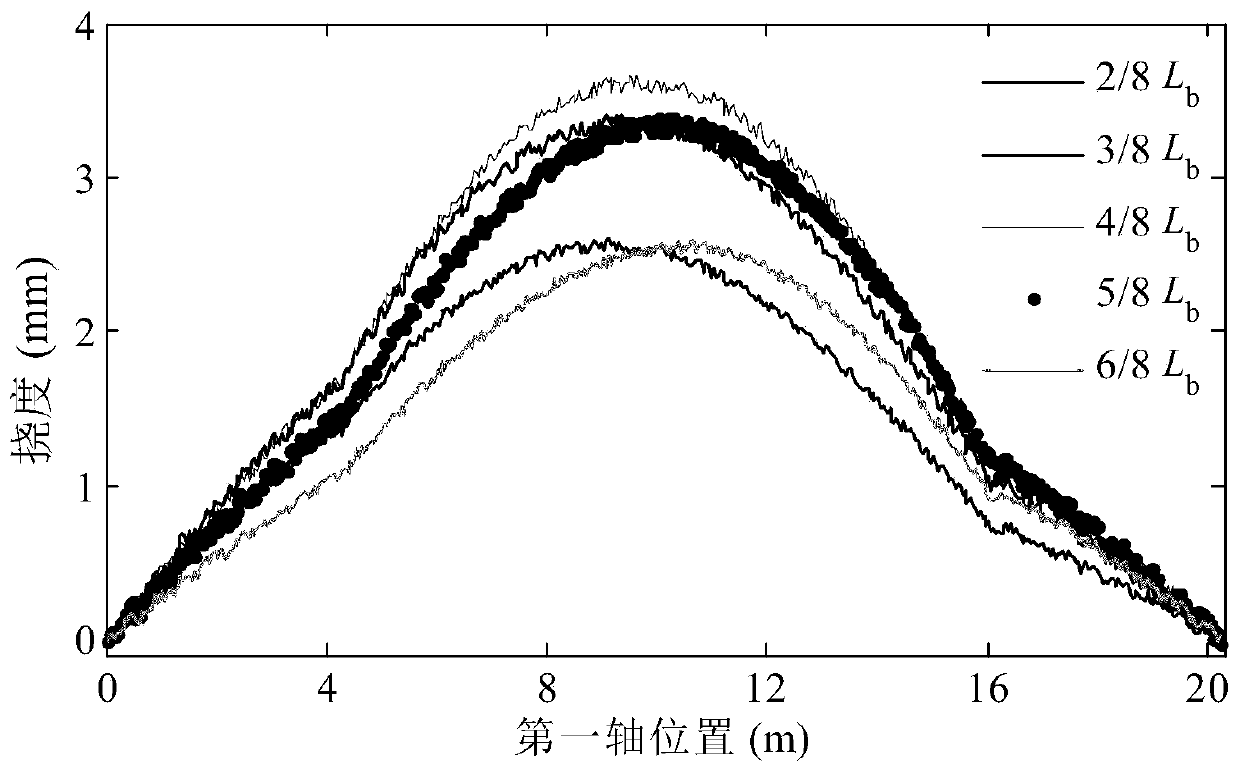

[0128] The main parameters of the simply supported beam bridge used in numerical simulation include: bridge length L b =16m, flexural rigidity EI=4.36×109N·m2, linear density ρ=1.07×104kg / m, damping ratio 0.02. Two types of damage are considered in the numerical simulation, single damage: l s =6.5m, δ=1m, α=0.2; two damages: l s1 =7.5m and l s2 = 11.5m, δ 1 = 1m, α 1 = 0.3, δ 2 = 1m, α 2 = 0.2. In order to ensure the accuracy of the numerical simulation, a lower vehicle speed with an average speed of 2m / s is adopted, and the impact of road irregularities is not considered at low speeds. A certain white noise signal is added to the dis...

Embodiment 2

[0138] Model introduction

[0139] A laboratory model test was performed to further verify the damage detection method based on the influence line of the bridge of the present invention. The test site layout is as Picture 10 , The test composition includes: bridge model, lateral baffle, loaded vehicle, speed acquisition device, displacement sensor and dynamic signal test instrument. The main girder of the bridge model consists of two independent steel beams, one of which is a three-span test beam with 1.5m upper bridge span, 5m test span and 1.5m exit span. The test span creates artificial damage. The other is an auxiliary beam. A smooth guide rail is fixed on the auxiliary beam to support the "V"-shaped wheel of the loaded vehicle so that the "V"-shaped wheel of the test vehicle can move linearly along the guide rail. The two I-beams are independent of each other, and the lateral spacing between their center lines is 0.258m, which is consistent with the lateral wheelbase of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com