Conduit lifting device and method used for injection of concrete into steel tubes of power transmission tower in upper air

A technology for concrete filled steel tubes and transmission towers, which is applied in the processing of towers, building materials, and building types, etc. It can solve problems such as low operating safety, slow lifting speed, and low operating efficiency, so as to reduce safety risks and increase safety , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

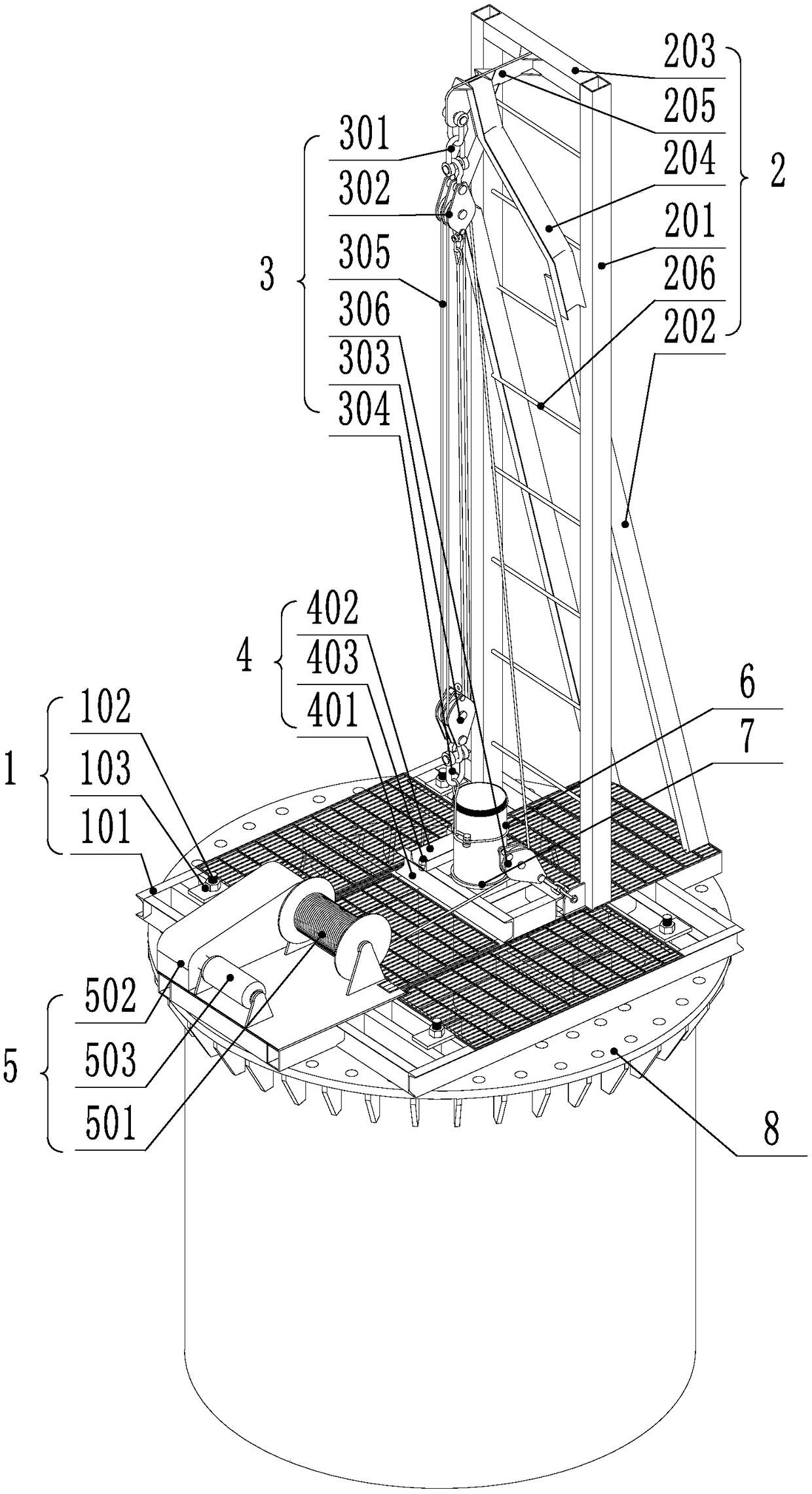

[0035] A conduit lifting device for high-altitude pouring of steel pipe concrete for transmission towers, which consists of 1 part of the base, 2 parts of the bracket, 3 parts of the wire rope pulley group, 4 parts of the fixed support of the conduit, and 5 of the hoisting mechanism, such as figure 1 shown.

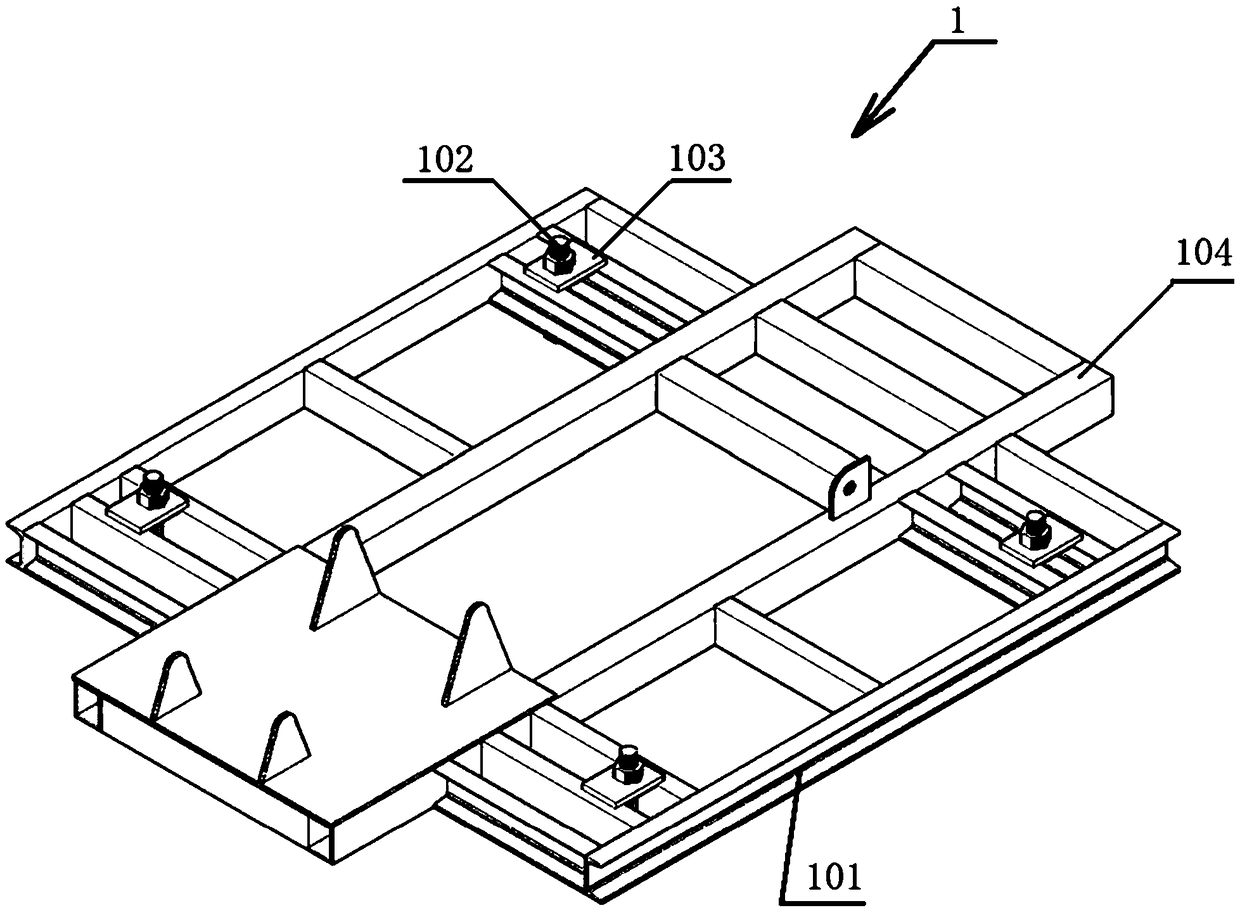

[0036] Among them: the base part 1 of the conduit lifting device is mainly composed of a bottom frame 101, a fixing bolt 102, and a backing plate 103, such as figure 2shown. The bottom frame 101 is made of square steel and channel steel welded into a whole frame, and long slot holes are arranged at the four corners for arranging the fixing bolts 102 between the bottom frame 101 and the steel pipe flange 8 . The specific position of the slotted hole is comprehensively determined by the bolt hole position of each steel pipe fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com